Modelling simulation calculations

Simulation with COMSOL Multiphysics®: Multiphysics for process optimisation in steel and process engineering

With COMSOL Multiphysics®, we offer powerful numerical simulations for complex physical phenomena in metallurgical and process engineering applications. Whether heat transfer, flow behaviour, reactions, or coupled multiphysics – we model processes, materials, and plant components realistically and efficiently.

Why COMSOL Multiphysics®?

COMSOL Multiphysics® combines an intuitive user interface with a powerful FEM engine and the ability to couple any physical phenomena, from heat and mass transfer to fluid flow and chemistry to electromagnetics and structural mechanics. For the steel and process industries, this means gaining valuable insights into thermal stresses, reaction zones, material behaviour, and energy losses. Ideal for developing robust processes and sustainable technologies.

Our services at a glance:

- Multiphysical FEM simulations (e.g. flow-heat transfer-reaction)

- Modelling of process reactions in blast furnaces, converters or reactors in general

- Thermomechanical analysis of components in high-temperature plants

- Gas and liquid flow in plant components (pipelines, nozzles, blow moulds, etc.)

- Creation of application-specific simulation apps for internal or external use

Integration and automation:

By connecting to Java or MATLAB interfaces, we implement automated workflows, sensitivity analyses and data-driven modelling.

Your added value:

Reduced development times, in-depth insights into complex processes and targeted process improvements, from basic research to practical optimisation.

Flow simulation with ANSYS Fluent®: Heat, gas flow and reactions

With ANSYS Fluent®, we simulate complex flow processes, heat transfer, chemical reactions, and dispersed multiphase flow in steel and process industry applications - accurately, efficiently, and realistically. Whether it’s industrial burners, entire furnaces, heat exchangers, or multiphase flows, we analyse real processes and support you in optimising your systems and products.

Why ANSYS Fluent®?

ANSYS Fluent® offers state-of-the-art CFD technology (Computational Fluid Dynamics) in an intuitive user interface. It enables the modeling of single-phase and multiphase flows, turbulence, heat and mass transfer, as well as combustion and reaction processes. The ANSYS product range allows for design and parameter studies to develop and optimize components and systems. This versatility allows us to offer you tailored solutions.

Our services at a glance:

- Simulation of gas and liquid flows

- Reaction modeling for combustion and reduction

- Modelling of blowing processes, injection systems and nozzle flows

- Multiphase flows (e.g., dedusting)

- Surface reactions (e.g., catalysts, chemical vapor deposition, corrosion)

- Heat transfer and thermal conduction in furnace and cooling systems

- Fluid-Structure-Interaction for component and process optimisation

High-performance computing and automation:

Efficient parallelization enables parameter-driven variant analyses within ANSYS Fluent's automation environment. In addition to a wide range of modern algorithms and models, Fluent offers the possibility to integrate custom, problem-specific modeling approaches directly and efficiently using User-Defined Functions (UDFs).

Your added value:

Fast, reliable results for informed decisions - from the design of new systems to solving problems and increasing efficiency in existing setups. Simulation that delivers - precise, fast, and clear! We make your processes visible.

Gas network calculations with Flomaster®

We offer digital mapping of gas networks ranging from individual plants to site gas networks. This allows us to evaluate the effects of various operating modes, start-up and shutdown processes, as well as emergency shutdowns on the entire gas network and connected components, and to derive appropriate measures. We use the Flomaster® simulation software for this work.

Why Flomaster®?

Flomaster® can be used to perform steady-state and transient simulations for incompressible liquids and compressible gases in pipeline networks. The software has a modular structure, which means that individual modules can be selected for specific tasks and linked together to display an entire network. Flomaster® thus enables the investigation and analysis of time-dependent processes, such as those that occur during start-up and shutdown of systems or the discontinuous feeding of media into a gas network. This enables the visualisation of temperature, pressure, and mass flow fluctuations and to record and evaluate their impact on the network.

Our services at a glance:

- Mapping of gas networks with the Flomaster® software

- Stationary and transient simulation of gas networks, particularly with regard to pressure and volume flow distributions

- Simulation of scenarios under various boundary conditions and evaluation of the impact of transient processes

Your added value:

- Analysis of transient processes (e.g., pressure surges caused by emergency shutdown of a plant) and their impact on the plant's internal gas network and connected systems

- Optimization of the operation of control and quick-closing valves

- Prevention of downtime

Mass flow calculations for liquid media with SIMBA®

We offer digital mapping of liquid media cycles. Depending on their application, all dissolved and undissolved components contained in the media are taken into account. This offers the advantage of simulating the volume flow distribution within the cycle and also displaying the components contained, such as solids or dissolved ions, and calculating their distribution. For this work, we use the commercial SIMBA® software, one of the leading platforms for material flow simulations.

Why SIMBA®?

SIMBA® enables the mapping of cycles and the integration of a wide variety of treatment plants such as settling tanks, cooling towers, or gravel filters, which are typically used in the steel industry and other process industries. Specifically for these industries, a database/library of treatment plants has been created in the platform over the past few years, which we draw on. In addition to distributing the volume flows within the respective cycle, individual components can also be viewed and simulated. An expansion to include energy content and heat quantity simulation is meanwhile available.

Our services at a glance:

- Balancing of water cycles

- Digital mapping of water cycles using SIMBA® software, taking into account the dissolved and undissolved components contained therein

- Integration of new treatment processes for separating components from the cycle or for extracting heat

- Simulation of scenarios, taking into account production planning and other future changes on the part of production or cycle management

Your added value:

- Forecasts for process water, chemical, and energy requirements

- Process and resource optimization

- Avoidance of downtime and bottlenecks

- Optimal planning of maintenance measures

- Digital testing of new process water treatment plants

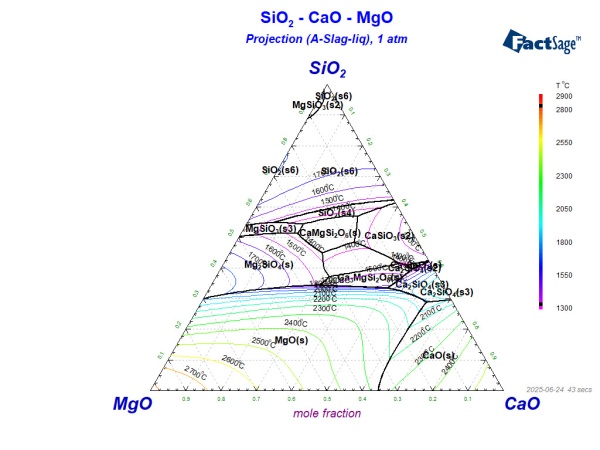

Thermodynamic calculations with FactSage® – Focus on steel, iron, slag, and residual materials

We offer sound thermodynamic modeling and equilibrium calculations for metallurgical processes, focusing on steel, hot iron, slag systems, and the recycling and evaluation of residual materials. We rely on the established FactSage® software, one of the world's leading platforms for thermochemical calculations.

Why FactSage®?

FactSage® combines powerful calculation modules with extensive, validated thermodynamic databases. This allows complex high-temperature processes to be simulated precisely – such as phase equilibria, material distributions, and reaction paths in systems with many components. FactSage® delivers reliable results, particularly in the field of iron, steel, slag, and oxidic residues – ideal for process optimization, quality improvement, and sustainable material cycles.

Our services at a glance:

- Thermodynamic equilibrium calculations for primary and secondary metallurgy

- Slag and process gas optimization to reduce metal losses and emissions

- Evaluation and thermal treatment of residues and recycled materials

- Calculation of phase diagrams, melting behavior, and reaction pathways

- Modeling of gas-metal, slag-metal, and solid reactions

Automation and data integration with Python

To efficiently handle complex issues, we seamlessly integrate FactSage calculations into Python-based workflows. This enables automated scenario calculations, data analyses, and connections to other simulation or process data sources.

Your added value:

Reliable data for sound decision-making—from process optimization and sustainable waste recycling to material development.

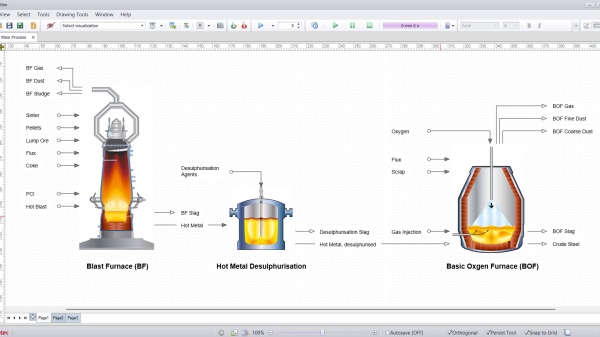

Flowsheet simulations with HSC Chemistry® – Holistic modeling of metallurgical processes

We offer professional flowsheet simulations with HSC Chemistry® for the analysis, optimisation, and evaluation of metallurgical processes—from primary metallurgy to recycling and waste utilization.

Why HSC Chemistry®?

HSC Chemistry® is an established tool for thermodynamic modeling and process simulation in the metal and recycling industries. The HSC-SIM module in particular enables the dynamic mapping of complex process chains, including material and energy flows.

Our services at a glance:

- Creation and optimisation of complete process flow diagrams (flowsheets)

- Material flow balances for metallurgical and chemical processes

- Evaluation and integration of residual materials and recycled materials

- Analysis of energy consumption and mass balances

- Support with scale-up, feasibility studies, and process development

Your advantage:

Holistic simulation provides you with a reliable basis for decision-making for economical and sustainable process management – from raw material processing to product refinement or recycling.

Targeted improvement of manufacturing processes – simulations with Simufact

We support companies in the analysis and optimisation of forming and manufacturing processes using simulation-based methods. With Simufact, processes such as forging, rolling, deep drawing, cutting and thermal processes can be virtually mapped, analysed in detail and evaluated.

Why Simufact?

The simulation software is based on MSC Marc and enables realistic, physically sound simulations. This allows for precise analysis of material behaviour, temperature profiles, tool loads and mechanical properties. The result is efficient process optimisation and reduced experimental effort.

Our services:

- Non-linear and linear multi-body FEM simulations

- Analysis of thermal, mechanical and contact-related processes

- Optimisation of processes and components

- Meaningful visualisation of results

Typical applications:

- Evaluation of component properties

- Identification of critical stresses

- Optimisation through adapted parameters

- Development of new processes

Your advantage:

Simulations enable early fault detection, shorten development times and reduce practical testing. With our experience, we offer practical, efficient support.