CO2 reduction and energy efficiency

The BFI has been actively involved in shaping the transformation to a climate-neutral process industry for many years. This includes reducing CO2 emissions and lowering energy requirements throughout the entire process chain. The use of H2 for reduction or in thermal process plants is being trialled in the BFI technical centre and in an industrial environment, and measures to comply with emission values are being developed. All work is carried out in close co-operation with companies in the process industry.

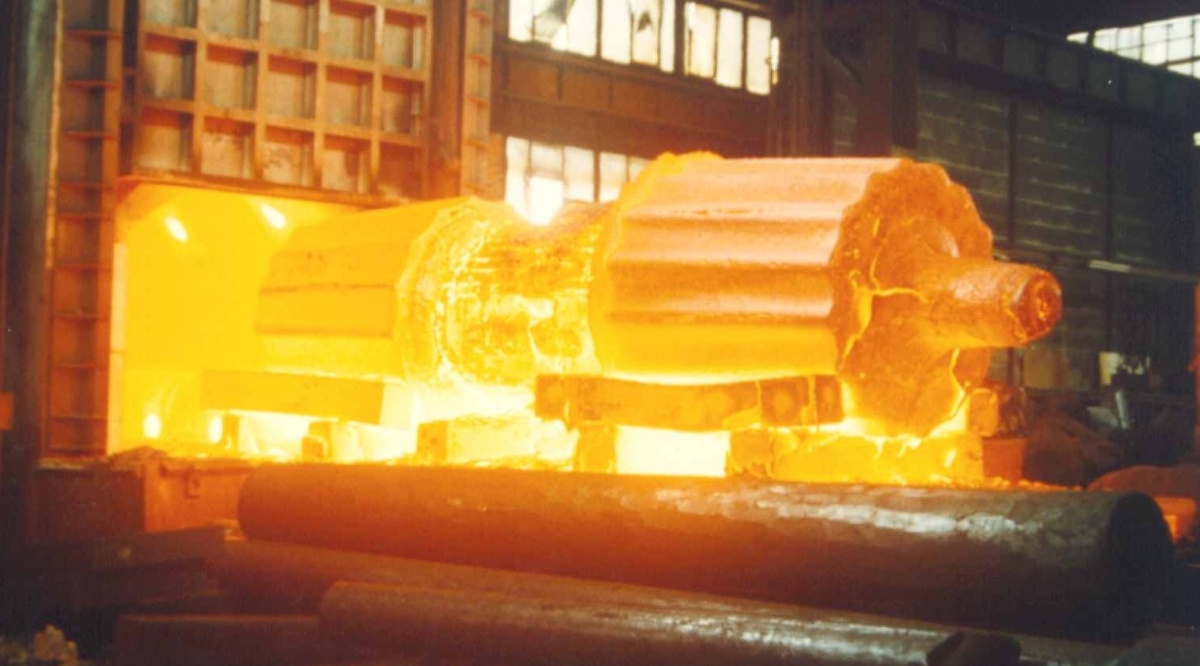

Testing the direct reduction route on a pilot scale

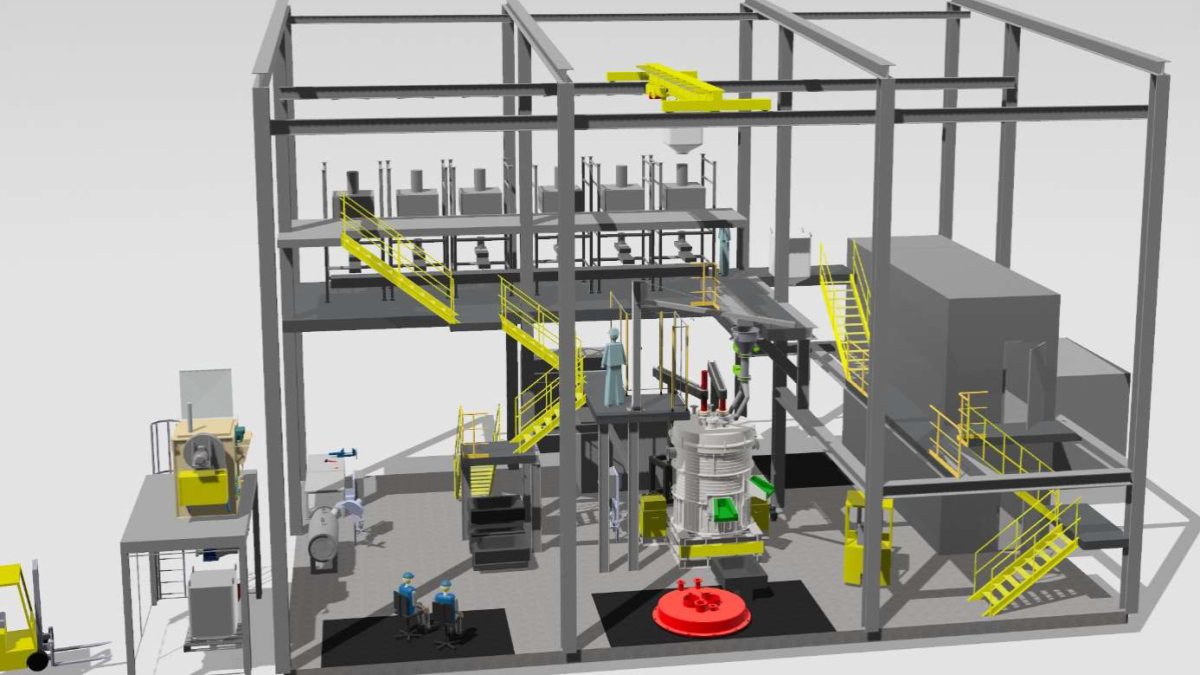

To test the direct reduction route, the BFI is conducting research with pilot-scale plants. As part of the BMWK-funded project "H2Stahl", the BFI is building a direct reduction pilot plant and is carrying out test campaigns.

A test smelter is being built as part of the DRI smelter project funded by the Ministry of Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia. The BFI is responsible for the scientific management of the test campaigns. Thanks to its proximity to Carbon2Chem and the steelworks, the entire process chain through to pig iron can be mapped and scientifically researched close to industry.

This is accompanied by experimental investigations in the BFI technical centre and simulations.

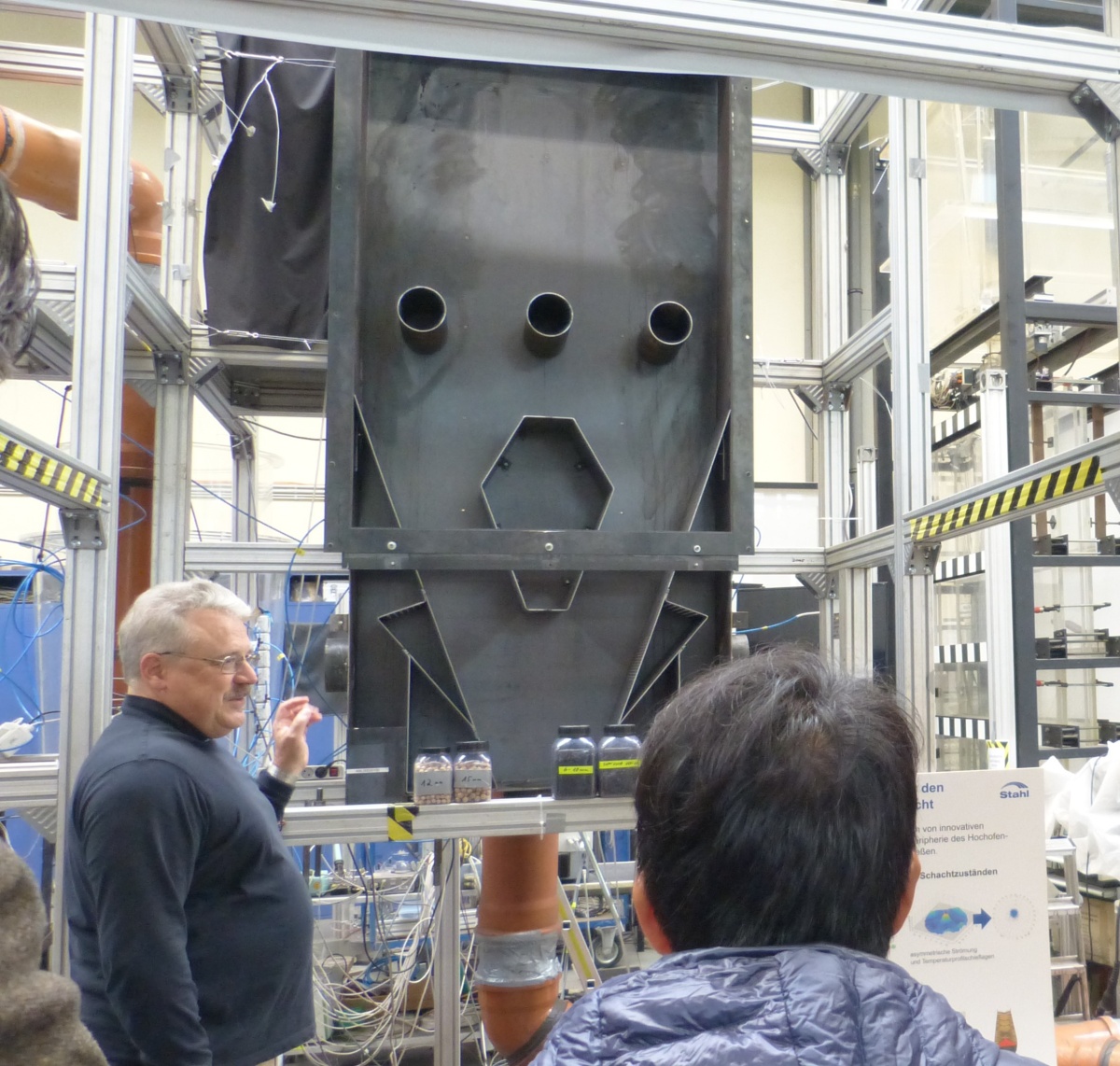

As part of the EU-funded MaxH2DR project, the BFI has set up a demonstration plant to analyse the movement of solid and gas and combines this with an online-capable 3D process model.

Use of hydrogen and ammonia in thermoprocessing systems

To reduce CO2 emissions in the process industry, R&D projects for the safe and efficient combustion of H2, natural gas and their mixtures (up to 100 % H2) are being carried out at the BFI (HYDREAMS, H2-DisTherpro, H2-HotRoll). Burners with an output of 50 - 600 KW are systematically investigated at the high-temperature pilot plant and with the help of CFD simulations (Fluent) and optimised for the respective application. It is expected that some small and medium-sized companies in the process industry will not be able to be connected to the hydrogen network and will therefore have to be supplied with climate-neutral NH3 as an alternative energy source. In addition to the H2 infrastructure, the BFI is building an NH3 infrastructure at its high-temperature pilot plant for the necessary investigations into industrial implementation. Together with project partners, systematic investigations into the safe combustion of ammonia and ammonia/H2 mixtures in thermal process plants are to be carried out here as part of R&D projects.

Electrification of thermoprocessing systems

Together with its partners, the BFI has developed a hybrid radiant tube for the flexible use of fuel gas and electricity and successfully tested it at the MeTA (HyBeSt). This is suitable for use in hot-dip galvanising plants, as the same sizes are used in the temperature range of up to 1300°C. Further development work is currently being carried out in this area (Synergie3).

New systems for effective waste heat utilisation

The BFI develops various concepts and demonstrators for waste heat utilisation in the high-temperature range, e.g. for media preheating (combustion air up to 1000°C) (REKUKER, OptiReg 2) or power generation, e.g. by means of TEG (thermoelectric generator; up to 600°C) (INTEGA, PowGETEG, InTEGrated) and implements these operationally.

Most of the newly developed systems are tested at the BFI's high-temperature pilot plant.

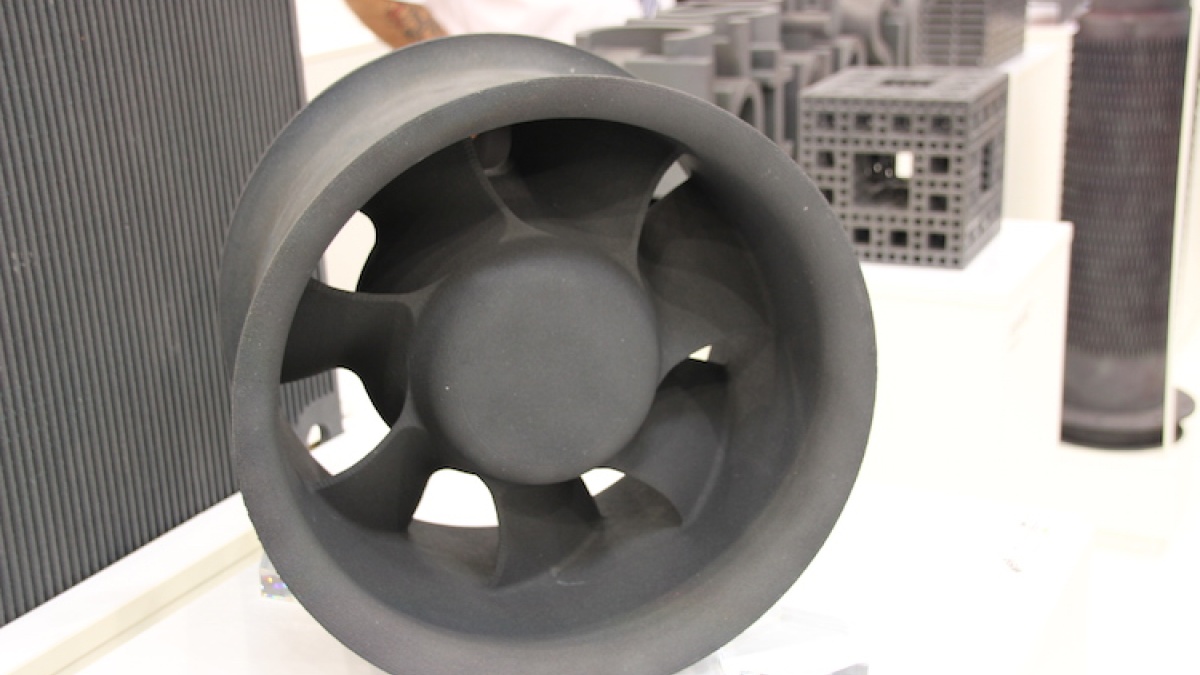

Components and coatings for high-temperature applications

In addition, good transport rolls with a new type of reflective surface were developed for use in preheating furnaces (furnaces > 1000°C) of hot-dip galvanising plants and tested in the technical centre (MeTA) and in operation (STEBGUT, ReflexRolle). In order to reduce waste heat losses, a new composite material consisting of refractory material and aerogel was developed and operationally tested as part of a joint project (AeroRef). The new composite material can be used up to a temperature of 1000°C.

Further development of processes for gas treatment and utilisation

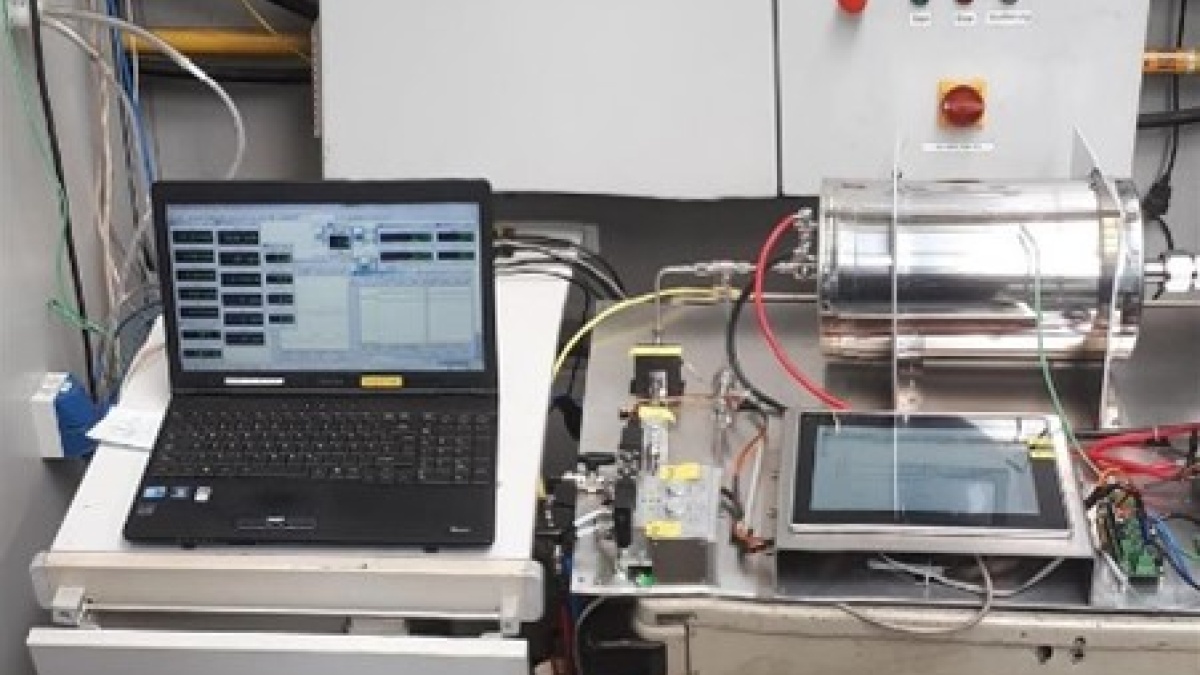

The BFI is investigating membrane processes for separating H2 or CO2 from gas mixtures. In the MemKoWi project, funded by the Federal Ministry for Economic Affairs and Energy, a membrane plant is being set up in the technical centre as well as a mobile test plant suitable for industrial use in a container. Areas of application include the separation of H2 from exhaust gases from steel production, the purification of H2 from process gases and H2 recovery and recirculation on continuous annealing lines.

Heating concepts are analysed, further developed and individually optimised for efficient fuel gas utilisation. This includes the metrological recording and control of gas quality fluctuations (SelGaKat), media preheating up to 1250°C and oxygen enrichment of the combustion air. Measuring systems for the fast and precise determination of combustion parameters have been developed and utilised for this purpose.

Strategic projects as part of the transformation

The BFI is involved in strategically important projects for the process industry in the context of CO2 reduction/decarbonisation and thus supports the industry in its transformation. Here are a few examples: InnoGuss, TransHyDE, DissHEAT, ReInvent, AMIGDALA. On the IN4climate.NRW platform, which is unique in Germany, the BFI works together with industry, science and politics on innovative strategies for a climate-neutral industry. The BFI is also involved in the accompanying scientific project on industrial transformation (SCI4Climate.NRW), in which NRW serves as a model region. Here, transformation paths for the climate-neutral production of steel, chemical base materials, cement, glass or paper are analysed, which prerequisites and new infrastructures are needed for the changeover and what contribution the circular economy can make.

Simulation calculations to optimise the processes

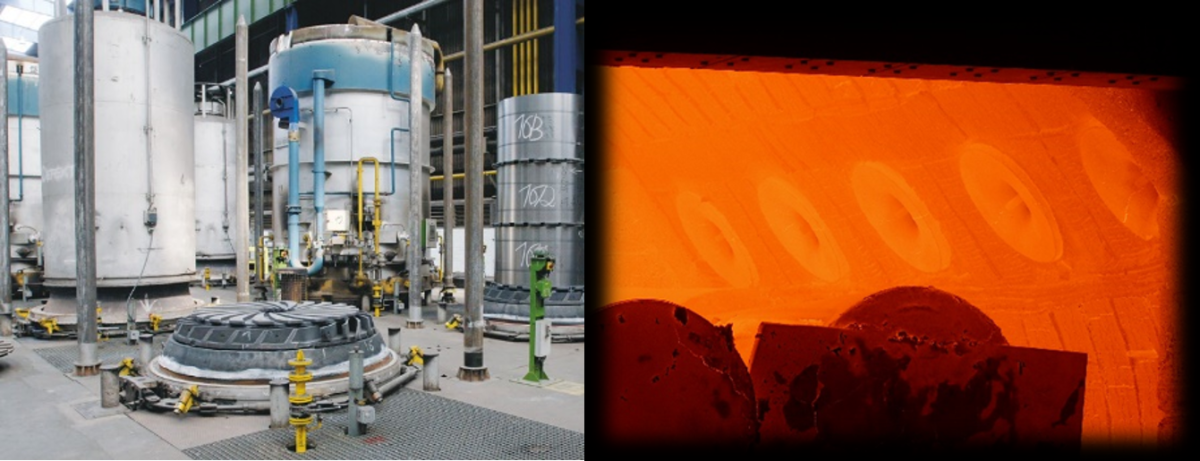

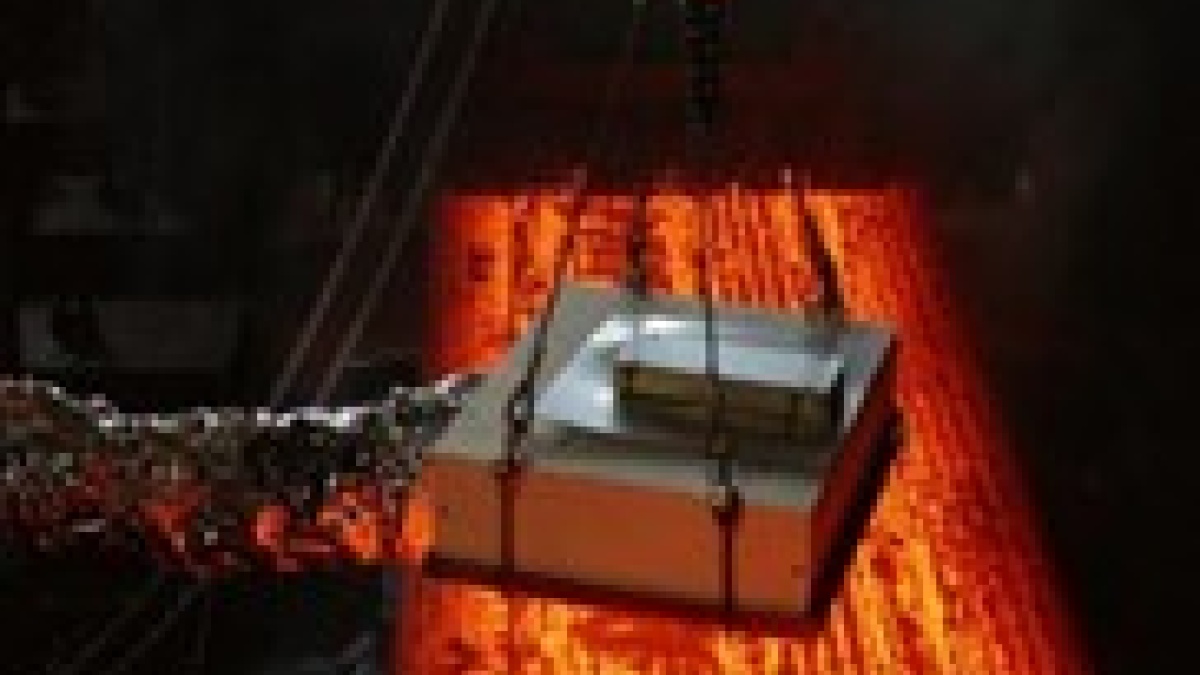

In order to reduce energy requirements and CO2 emissions, the complex processes in electric arc furnaces and blast furnaces are analysed using numerical simulation, new measurement techniques and dynamic process models. New methods must be developed for this in order to be able to carry out the simulation calculations with reasonable computing time and memory requirements (see SimulEAF). The dynamic process models are continuously being expanded and new measurement techniques integrated in order to enable more precise energetic process control (see DiGreeS).

The fibre-optic measurement of the temperature at the thermally highly stressed tip of blast furnace tuyeres is an example for an innovative messurement technique. The results of these measurements are incorporated into process models and blow mould simulations and make an important contribution to the development of measures to extend the service life of blast furnace blow moulds.

Projects on this topic

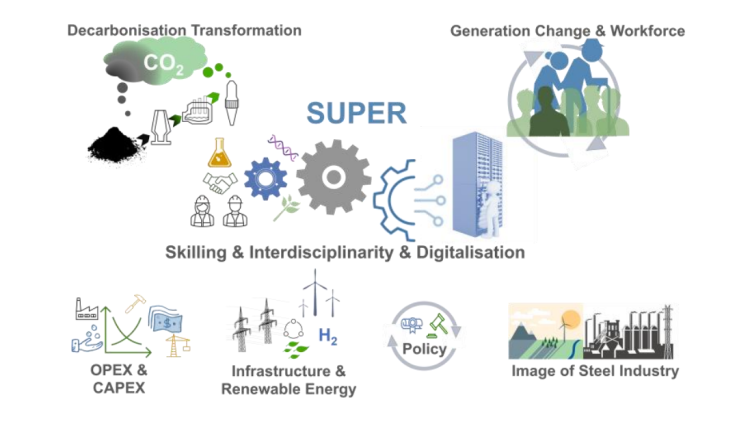

SUPER - Sustainable future steel production and people recruiting and skilling

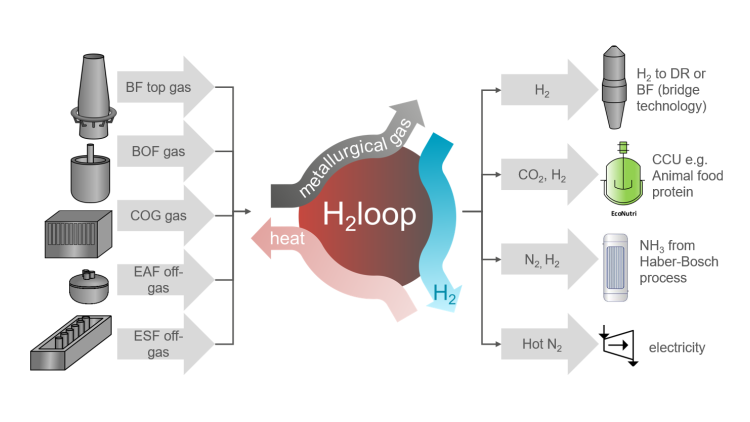

H2loop - Sustainable decarbonisation of integrated steel plants by hydrogen production from chemical looping

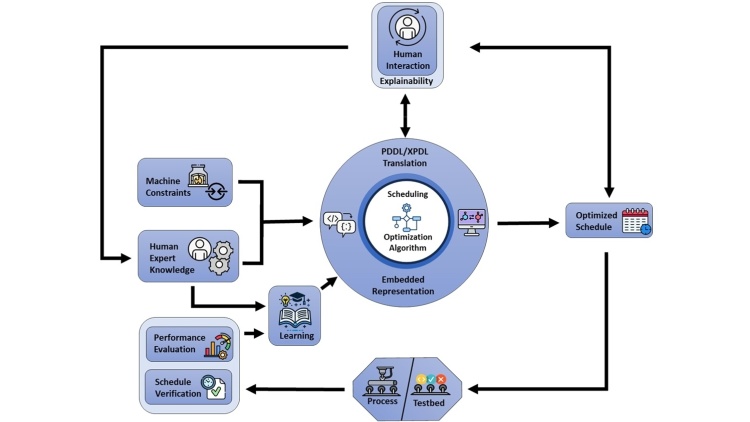

DeepScheduling - Explainable AI and Human-Centric Learning Solution Framework for Industrial Scheduling Optimization

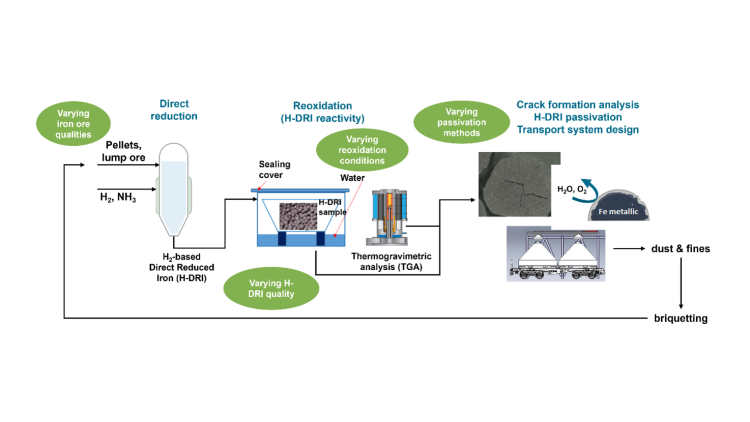

Safe H-DRI - Safe transport of DRI from H2-based direct reduction considering quality-related H-DRI reactivity, stability, the efficiency of passivation methods and health and recycling aspects

Your contact persons

1 Dr.-Ing. Bernhart Stranzinger

+49 211 98492–366

bernhart.stranzinger_at_bfi.de

28 Theresa Overbeck, M.Sc.

+49 211 98492-212

theresa.overbeck_at_bfi.de