Project overview

CO2 reduction and energy efficiency

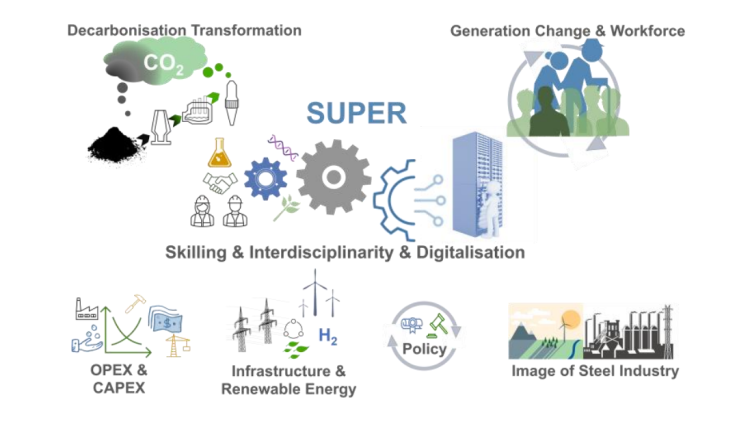

SUPER - Sustainable future steel production and people recruiting and skilling

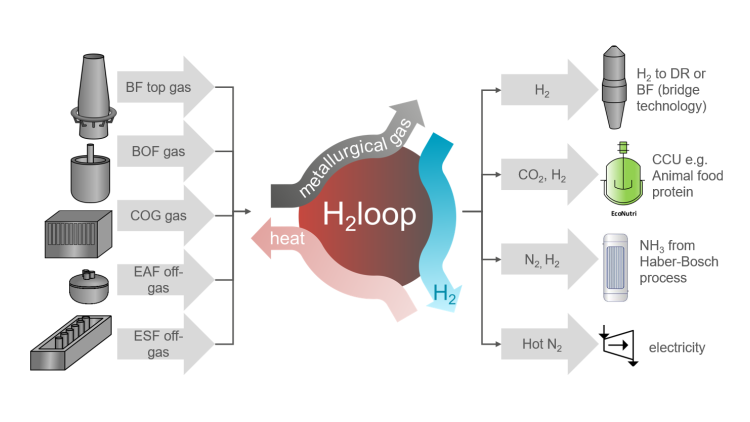

H2loop - Sustainable decarbonisation of integrated steel plants by hydrogen production from chemical looping

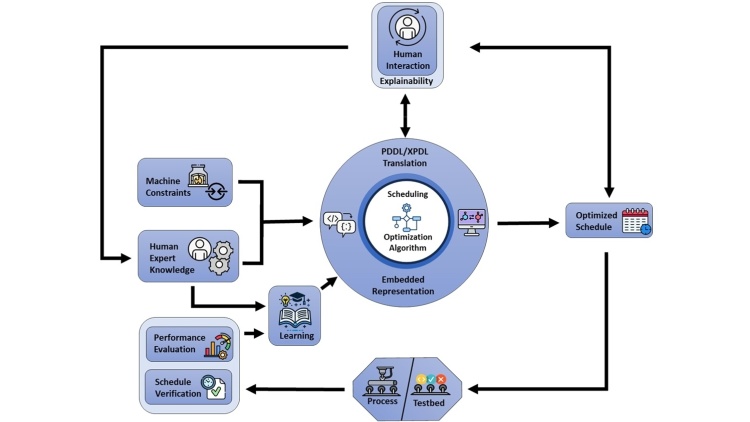

DeepScheduling - Explainable AI and Human-Centric Learning Solution Framework for Industrial Scheduling Optimization

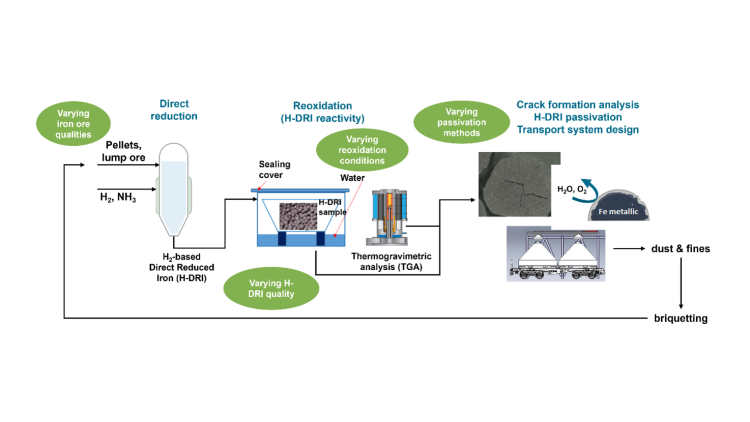

Safe H-DRI - Safe transport of DRI from H2-based direct reduction considering quality-related H-DRI reactivity, stability, the efficiency of passivation methods and health and recycling aspects

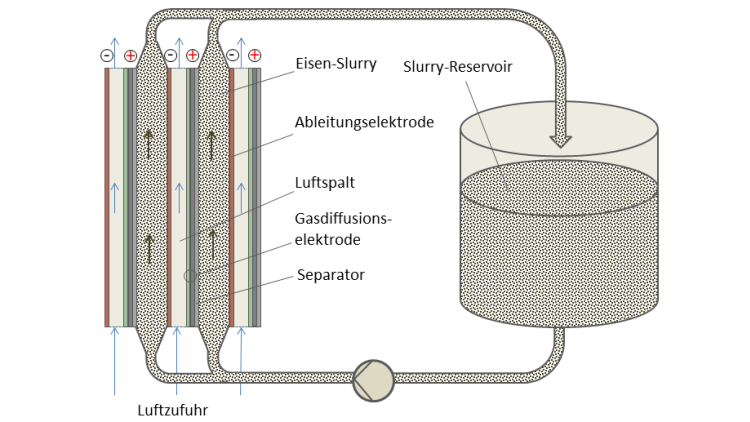

FeEnCap - Encapsulated iron materials for new type of iron slurry/air batteries

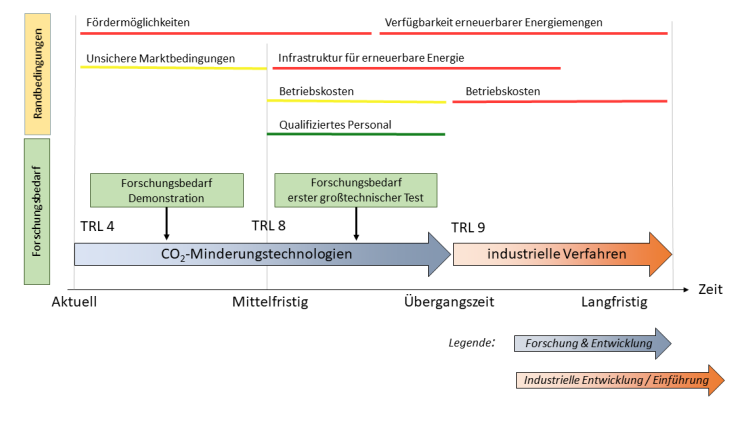

SCI4climate.NRW - Scientific support of the climate-neutral transformation of industry

H2II - Hydrogen sequence impulse injection into the Blast Furnace shaft

H2TransBF2030 - Minimisation of CO2 Emissions from the BF by hydrogen containing injectants and use of HBI during transition to new Ironmaking processes until 2030

SynErgie3 - Synchronized and energy-adaptive production technology for the flexible alignment of industrial processes to a fluctuating energy supply

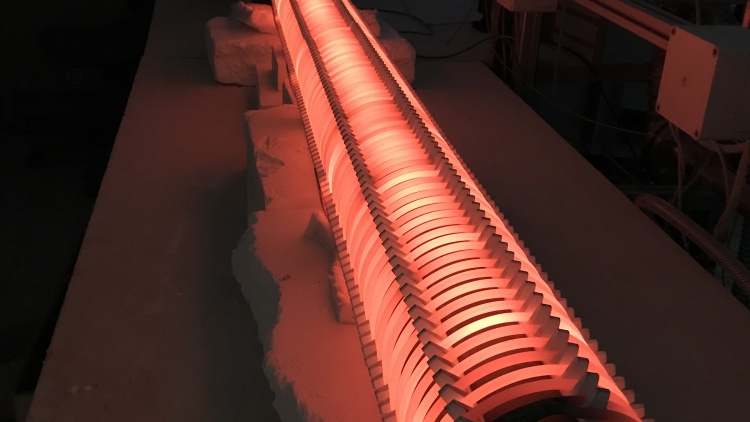

H2-HotRoll - Avoidance of CO2 emissions in the steel industry by utilizing of hydrogen in continuous thermoprocess plants on the example of reheating furnaces

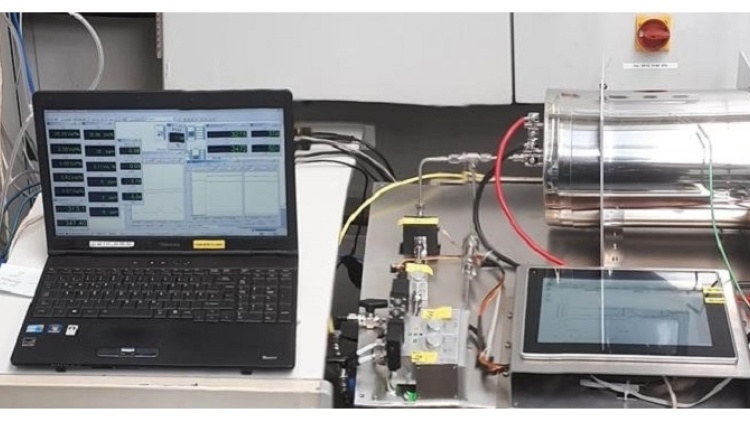

SelGaKat - Method for increasing the energy efficiency by selective gas quality measurement taking into account the hydrogen content using a catalytic reference combustion chamber

AMIGDALA - Alliance for Modelling Industries towards the Green Deal’s objectives And circuLArity

BeRefCo - Operational testing of a reflective furnace wall coating and determination of the influence on energy requirements and CO2 emissions

MemKoWI – Membrane processes for the separation of carbon dioxide and hydrogen from industrial gases

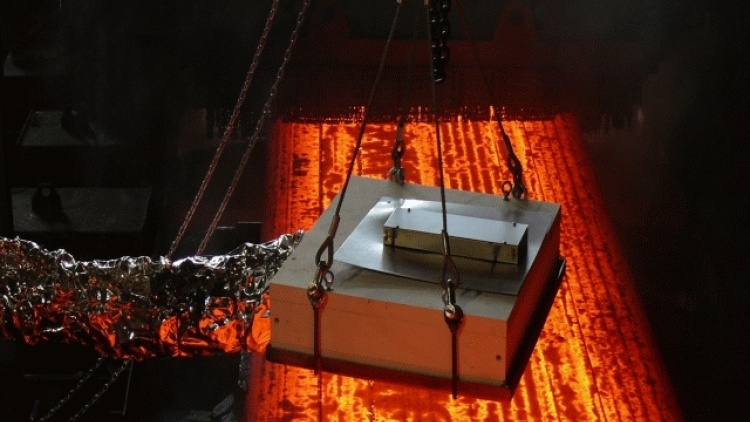

DRI-smelter – Novel process for the production of pig iron by melting sponge iron from direct reduction in a DRI smelter

ReInvent – Reduction of greenhouse gases

HYDREAMS - Clean hydrogen combustion and digital tools for reheating and heat treatment for steel

DissHEAT – Dissemination of the heating technology research results for emission minimization and process optimization towards todays fossil-free heating agenda

InTEGrated – Development of innovative TEG systems

InnoGuss – Development of innovative transformation paths for the decarbonization of the foundry industry in NRW

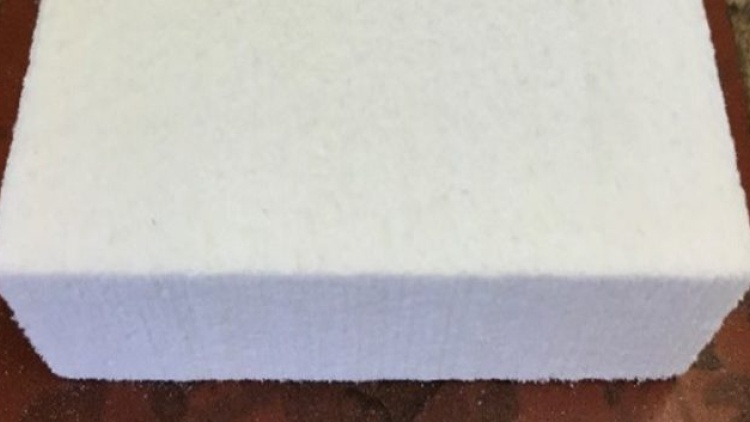

AeroRef – Reduction of energy demand in heating furnaces by new combination of aerogel and refractory

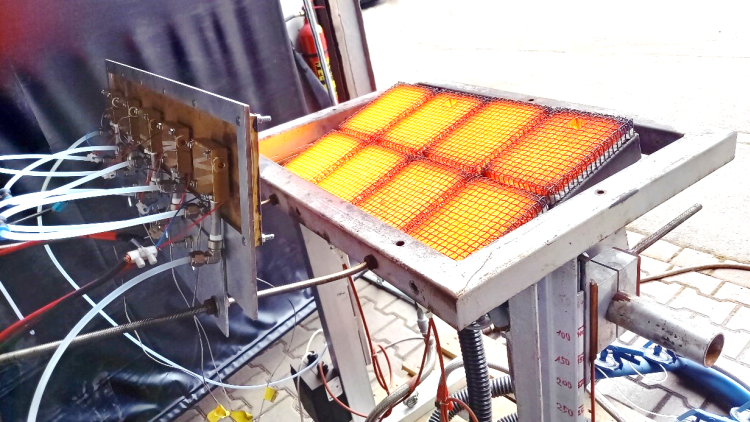

HyBeSt – Hybrid Heating in the steel industry

FlexElectricSteel – Intraday Energy Management for Electric Steel Plants

VEIK – Improvement of heat treatment and heating in industrial furnaces by new innovative ceramic hot gas fans

H2-DisTherPro – Avoidance of CO2 emissions in the steel industry by utilzing of hydrogen in batch-type thermoprocess plants on the example of batch annealing

H2Stahl – Hydrogen technologies for a successive decarbonisation of the steel industry

InnoKon – Innovative non-stick surface to increase the service life of oxygen lances on the converter

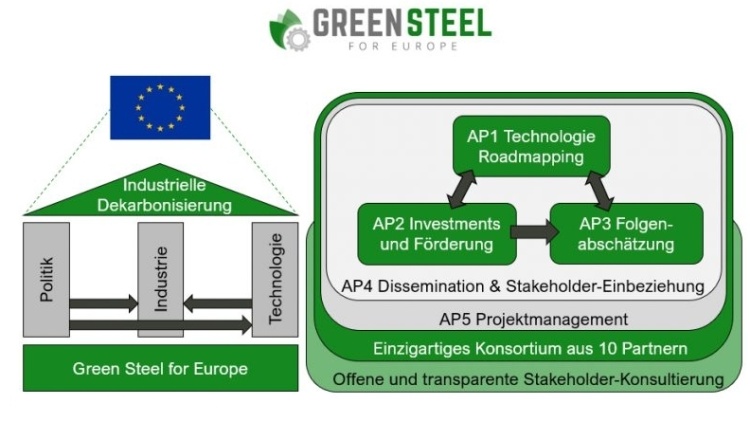

Green Steel for Europe

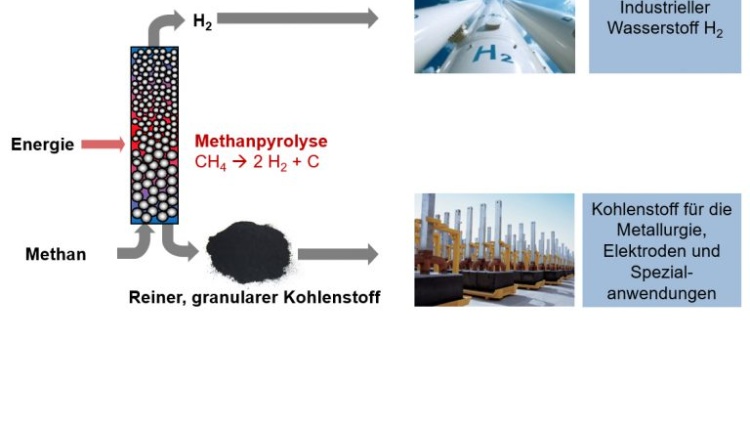

Me²H2-Methane pyrolysis

ReflexRolle – Development of a reflecting, anti-adhesive Coating for furnace rollers

STEBGUT – Furnace roller

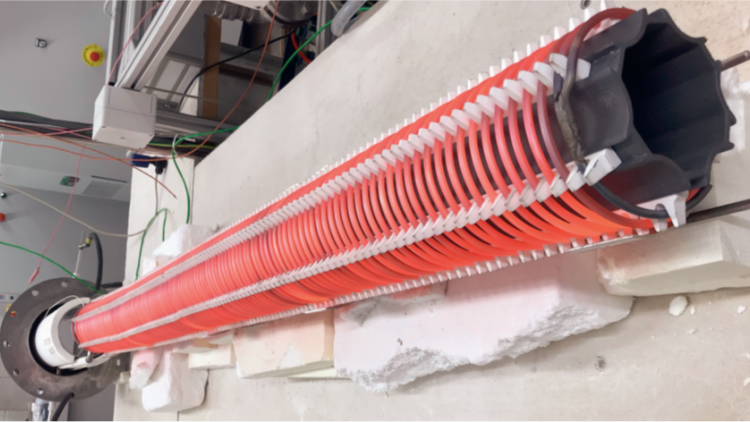

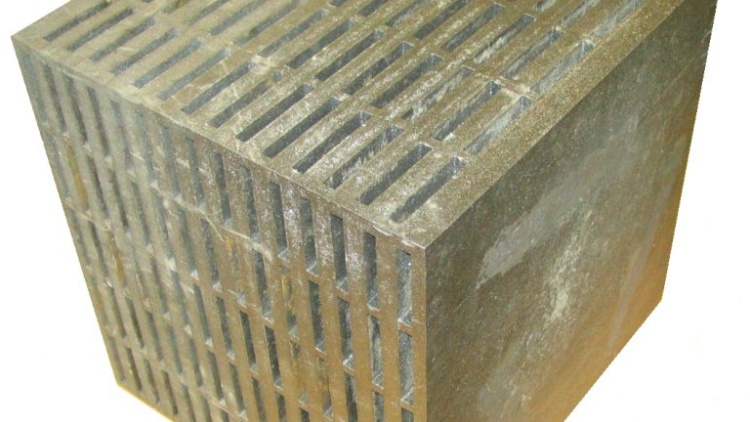

OptiReg2 – Heat exchanger

REKUKER – Ceramic heat exchanger

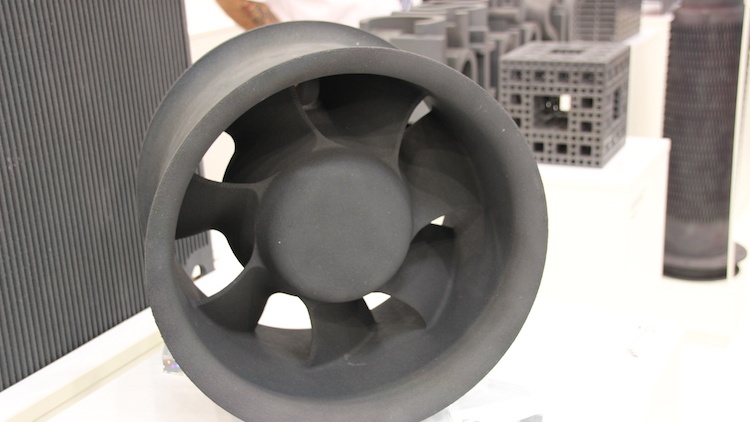

INCERV – Ceramic hot gas fans

NEBS – Use of waste heat for electricity generation using ORC

PowGETEG – TEG for high temperature waste heat recovery

INTEGA – Thermoelectric generators (TEG) for high temperature

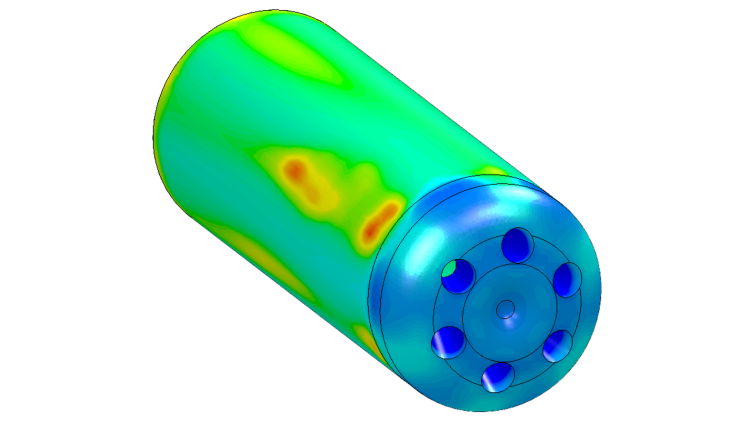

SimulEAF – Optimization of the processes in the electric arc furnace

PlantTemp – Plant wide control of steel bath temperature

PreventSecDust – Reduction of dust emissions in the furnace

Longlife Tuyere – New improved blast furnace tuyeres

TransHyDE_FP1 - System analysis of transport solutions for green hydrogen

REDERS – Reduced CO2 emissions by increasing the recycling rate in steel production

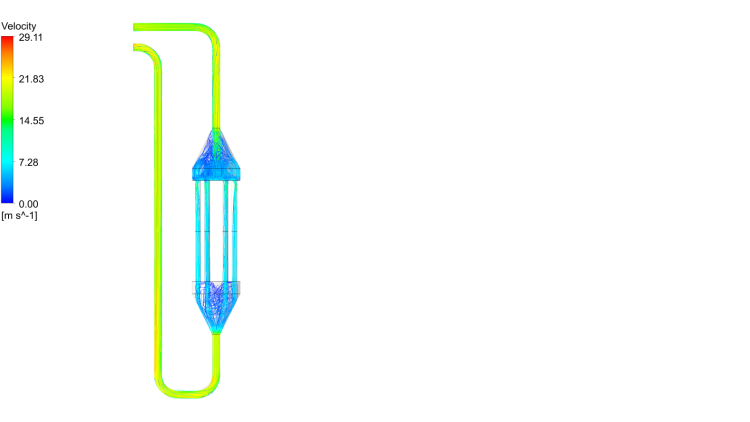

H2BF – CO2-Mitigation through injection of H2 into the blast furnace