Digitisation and Process Measurement

In the increasingly competitive energy-intensive process industry, resource-saving and consistently transparent processes offer a competitive advantage. The BFI supports you in the digital transformation towards a networked, customer-oriented supplier of individual products, even for small batch sizes. Innovative process measurement technology is used to digitize previously unknown process information and make it usable for AI-supported process control and cross-plant logistics. In the following sections, you will find some of our concepts as well as examples of research and development work that has already been implemented.

Process Measurement

Without sufficient online information about the status of the production process and the quality parameters of the product, neither the control of individual systems and process chains nor AI-supported digitalization solutions can be implemented. This is where BFI offers innovative ideas and industry-compatible solutions for process measurement technology. The following is a selection of our solutions.

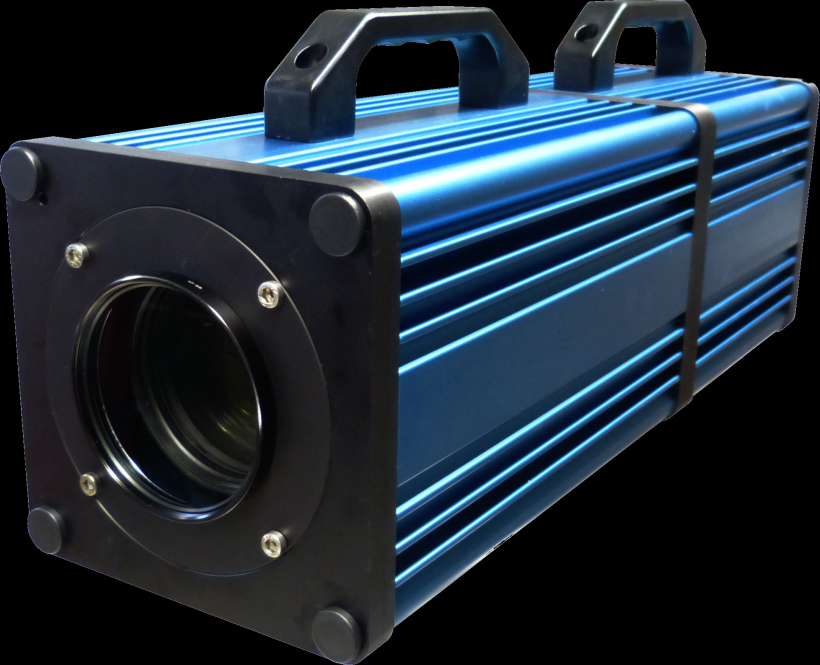

Camera Technology and Image Processing

BFI has been successfully using various types of cameras for process or product monitoring in conjunction with individual analysis software for many years. Visual, infrared, UV and hyperspectral cameras are used in industrial environments. Hot forgings (round and square) are measured with our non-contact diameter measurement system. TopPlan was used to measure the flatness of hot and cold coils.

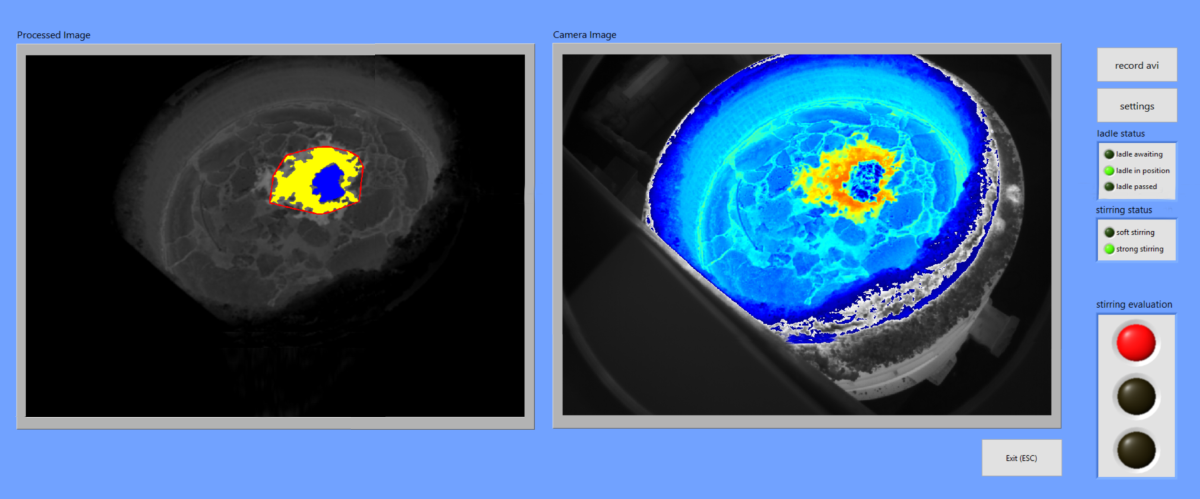

Solutions for determining the rinsing efficiency of the melt treatment in the rinsing stand (DynStir) and vacuum plant, deslagging (OptDeSlag) and casting powder monitoring (RealTimeCast-Support) are in industrial use. These solutions consist of a camera installed on the system (in the visual or infrared wavelength range) and downstream image processing using conventional and AI methods.

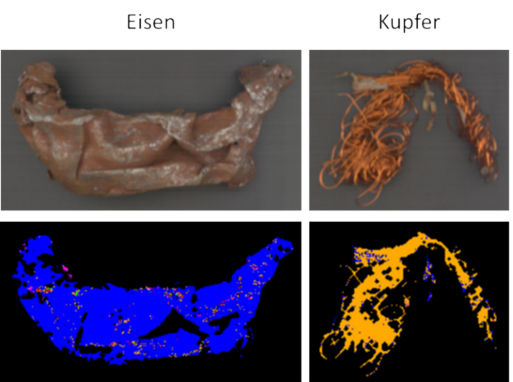

Hyperspectral cameras with different spectral ranges (VIS/NIR and MWIR) are successfully used in industrial environments for the identification of hard-to-detect foreign metal and plastic components in the production of high-quality recycled material (REDERS).

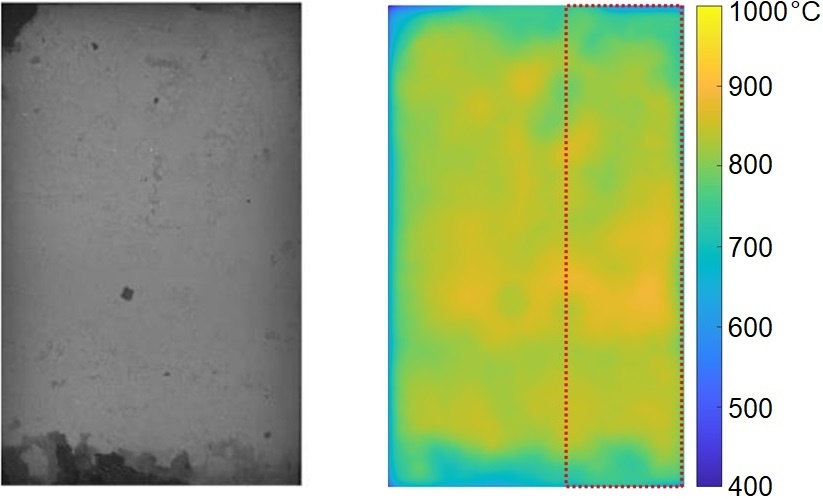

The detection of residual scale after primary descaling and the measurement of very thin secondary and primary scale layers on billets, slabs and strips was realized with SW, RGB and IR cameras (HiPerScale, INFIRE and ReduHeatLoss). With these measuring techniques, it is possible, for example, to estimate the product surface quality promptly, identify process deviations at an early stage and continuously influence descaling.

Acoustic Measurement Technology

Solutions for contactless vibration measurements for the detection of vibration-induced process conditions (e.g. sump tip detection, slag foaming) have been developed using acoustic methods (Con-SolCast).

Iron and acid content in pickles can be measured using an ultrasound technology developed in-house.

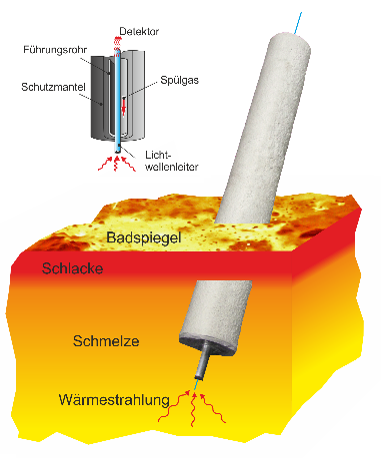

Fiber optic-based temperature measurement

Our patented method for the continuous measurement of temperature in metallic melts using fiber optic sensors (MeltCon) is being used very successfully. In an initial feasibility study, the fiber-optic measuring system was further developed in order to be able to analyse the chemical composition of the melt with regard to relevant elements (OMiAS).

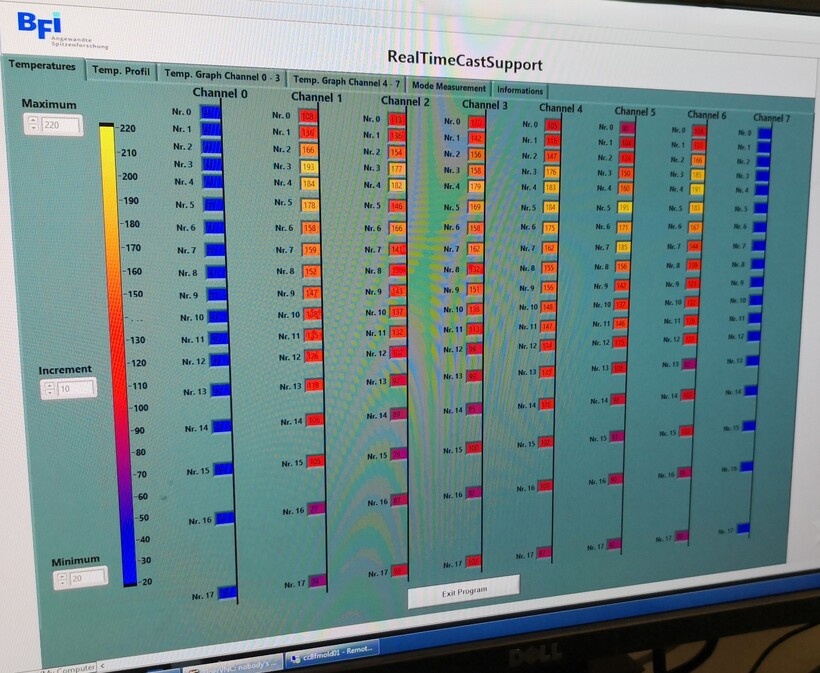

Through the development of evaluation software, applications for measuring the temperature distribution in the mould with fiber optic sensors have been successfully implemented in several projects (ConSolCast, OpConDigiCast, RealTimeCast support).

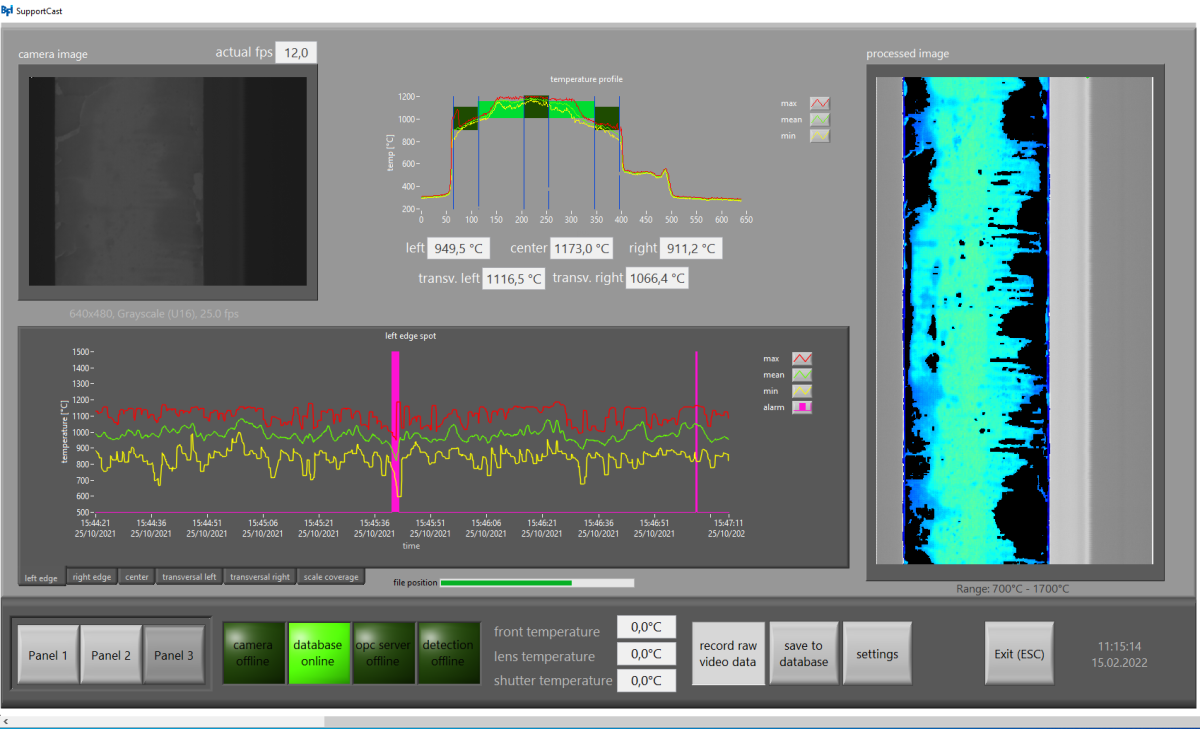

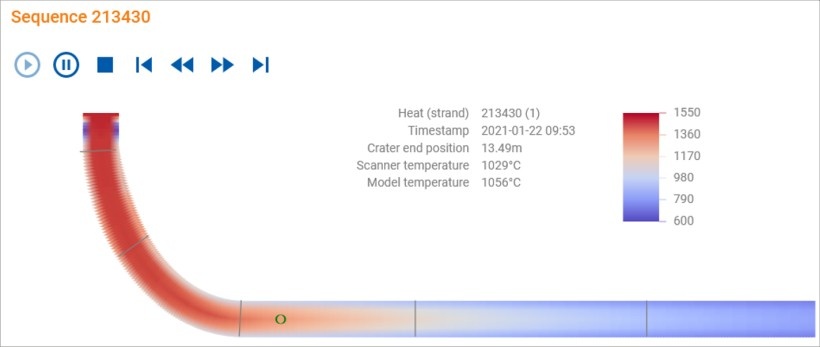

An IR camera with specially developed image processing software, which can also detect scale (SupportCast), was used to monitor the temperature distribution on the strand. The BFI is currently developing a self-sufficient sensor for measuring the temperature in the refractory of steel mill ladles (SmartLadle).

Digital Transformation

For many years, the BFI has been supporting the process industry in the digital transformation, the change to the age of knowledge and creativity. For the process industry, digitalization means the use of data and algorithmic systems for new or improved processes, products and business models that are shaped by digital technologies such as artificial intelligence and digital innovations.

Digital Twins

The data collected along a complex process chain is merged and evaluated in proactive digital twins and provides detailed information on the production process and the condition of the products. The specific requirements of industrial data, the correct tracking of products and the challenges of assigning data to constantly changing products must be taken into account.

Big Data and AI

Analyzing large amounts of data using modern artificial intelligence (AI) methods provides information on how a product can be manufactured more efficiently or how product quality can be improved. This always involves a process-stage approach and, where necessary, a cross-plant approach.

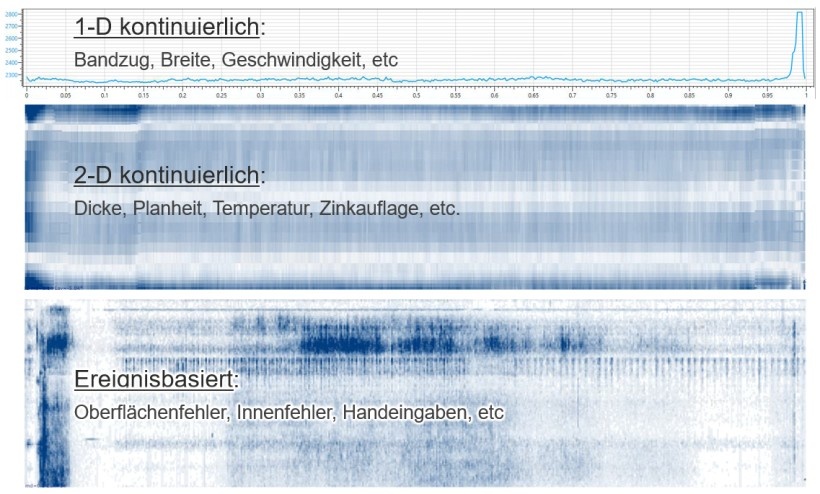

Examples of applications include the cross-process-stage analysis of large quantities of one-, two- and three-dimensional and event-based data, such as the classification results of surface inspection systems (EvalHD, CheckSIS), the analysis of a large number of measurement signals, the rapid search for similar process situations in process signals over long periods of time (SitErk) or the analysis of high-resolution time series process data with regard to the causes of errors to derive influential key factors (PRESED).

Machine Learning

The application of modern machine learning (ML) methods as a subset of AI offers the possibility of making the essential information usable from large amounts of data.

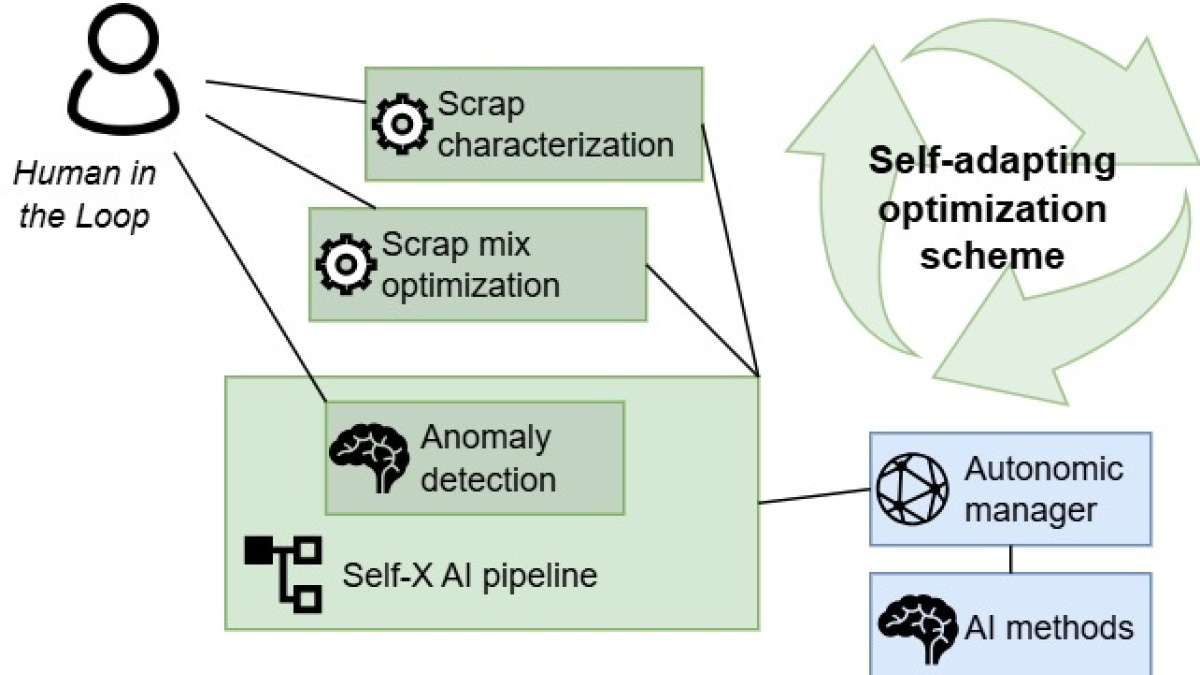

A human-centered approach is always important for the use of AI or ML in BFI. Through an innovative AI data pipeline with autonomous data processing functions, continuously updated AI applications can be developed that support the integration of data and an autonomous manager's role in the application through customized, trustworthy self-X AI technologies (s-X-AIPI).

The highest level of security, trust and seamless communication between industrial solutions supported by artificial intelligence and the users must be guaranteed. The ALCHIMIA project also uses methods of Federated Learning for the cross-plant optimization of hybrid process models. The BFI is also contributing its expertise to the Ruhr Metropolis Competence Center for the Working World of the Future with Artificial Intelligence (HUMAINE).

Decision support systems: Examples for quality and logistics

The increasing availability of large amounts of data and a multitude of process and product information, combined with challenging personnel situations in production companies, leads to an enormous workload for those responsible. Here, the BFI can contribute to a considerable reduction in workload through a variety of decision support systems tailored to the application.

For the evaluation of product quality, a set of rules is created using ML on the basis of historical decisions and, if necessary, adapted to changed process conditions and customer requirements (DeepQuality). In flat steel production, the expected flatness of the product can be estimated and thus provide the plant operator with valuable information on how the process should be run in order to achieve the best quality (HatFlat).

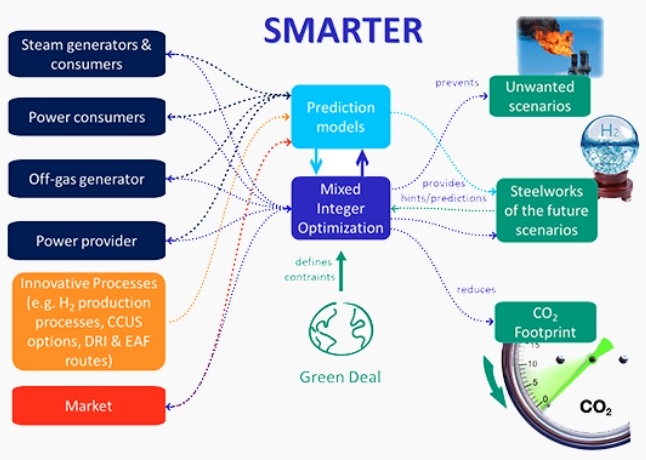

The performance of the systems with regard to the product quality required by the customer is crucial for the detailed planning of production upstream of the systems. Decision support based on a performance index provides valuable assistance here (DynReAct). With the help of advanced methods and tools, a solution was developed to support the optimized management of gas and steam networks in integrated steel plants with the aim of improving energy efficiency, reducing CO2 emissions as well as energy and administrative costs (SMARTER).

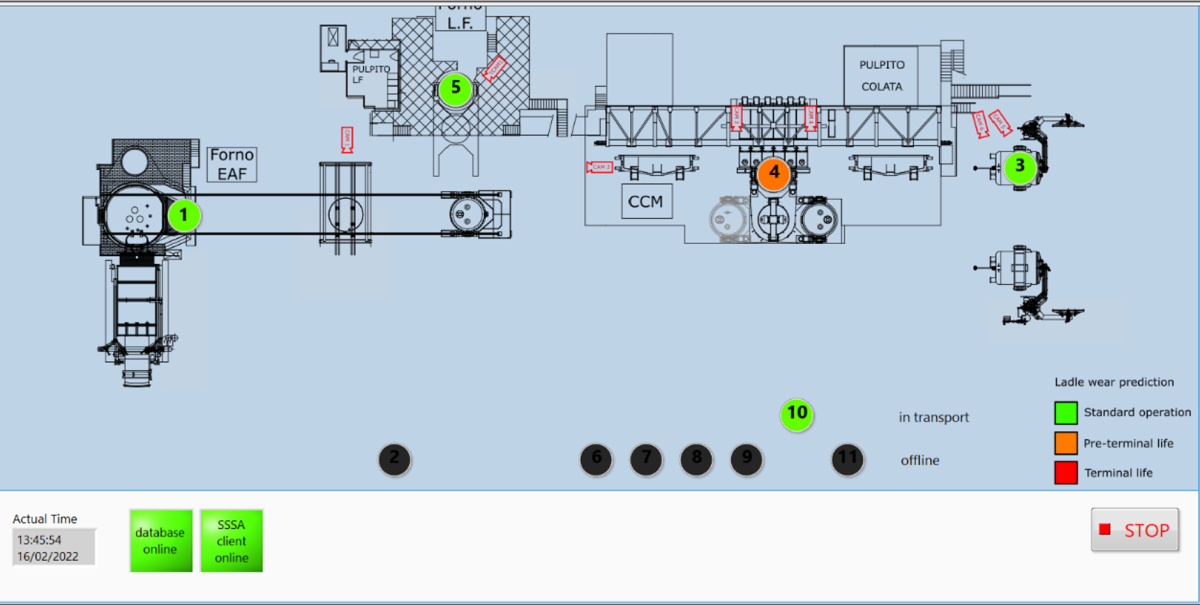

In order to implement Industry 4.0 in the steel industry, solutions are needed that track all intermediate and end products along the entire production chain. To make this possible in steelworks, the BFI has coordinated a project to optimise ladle logistics (TrackOpt).

Software solutions according to customer specifications

The availability of large amounts of data brings with it the challenge of pre-processing and evaluating them in a suitable form and presenting them in an optimized form for the respective user (production, quality management, technical customer consulting). Thanks to its many years of practical experience in applied cutting-edge research on site in the process industry, BFI speaks the language of users from the store floor to company management. This enables us to offer customised software solutions as stand-alone versions or web applications.

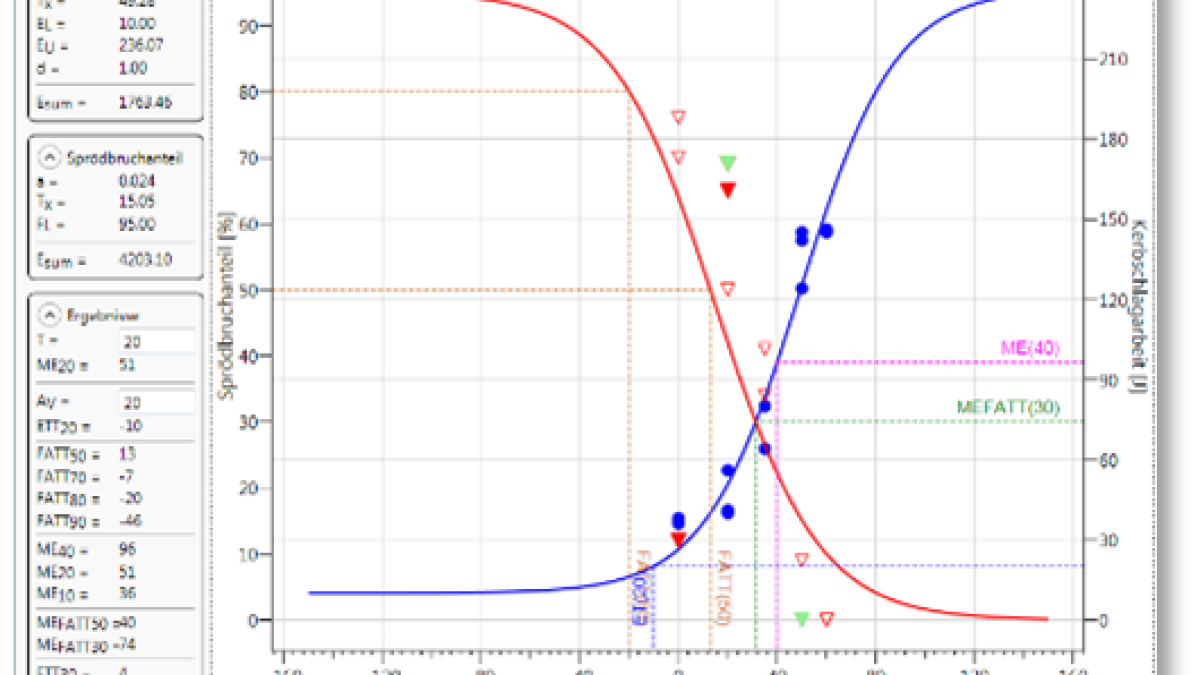

An example of a single-user application is the software for SEP test sheet 1670. This allows the compensation calculation for impact energy and brittle fracture percentage as well as key figures such as ME and ETT, which are defined in SEP 1670 and can be derived from the compensation curves.

For the implementation of software solutions, the BFI is involved in the development of European standards for the process industry (COCOP, CAPRI). The use of open standards (e.g. OPC/UA, MQTT) and established open-source components (e.g. JavaScript, Angular, Flask, React) ensures the maintenance and adaptation of BFI solutions even after the end of the project by the industrial partner itself or as a BFI service.

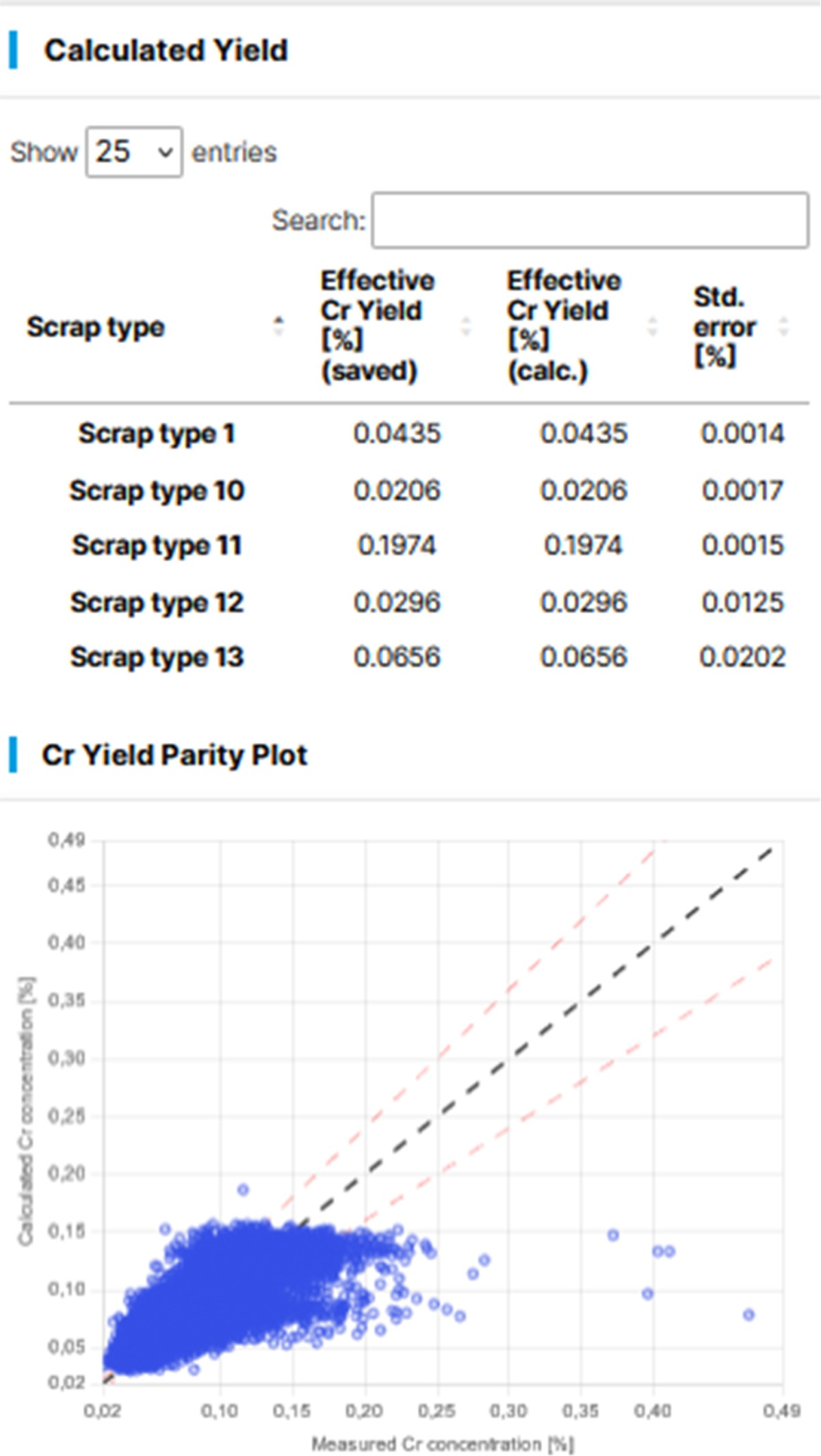

The BFI has developed web-based software for scrap characterization and scrap mix optimization based on ML evaluation of process data (REVaMP, ALCHIMIA, s-X-AIPI) to create a cost- and quality-optimized scrap mix for crude steel production. The process and quality data are fed in via database interfaces. The metallic yield and element content are calculated for each scrap type in use and their development over time is tracked. The current scrap properties are taken into account in the scrap mix optimization. The software tool also supports the evaluation and quality monitoring of the scrap delivered to the steelworks.

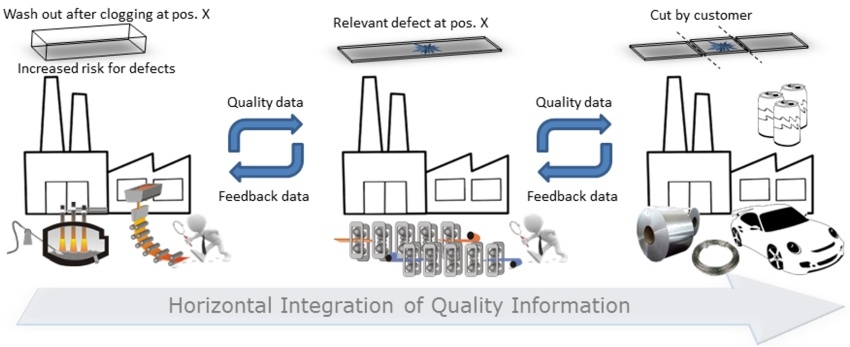

For the transfer of validated product-related quality data, which is increasingly required by customers in the process industry in addition to certificates, the BFI has developed an adaptive platform that realizes the horizontal integration of quality information across the entire supply chain (Quality4.0) in order to establish a new level of cooperation between customers and suppliers and to place a joint focus on the manufacture of products of the highest quality in times of challenging global markets.

Projects on this topic

AgiFlex - Agent-based models minimizing carbon usage in flexible and efficient future integrated steelworks

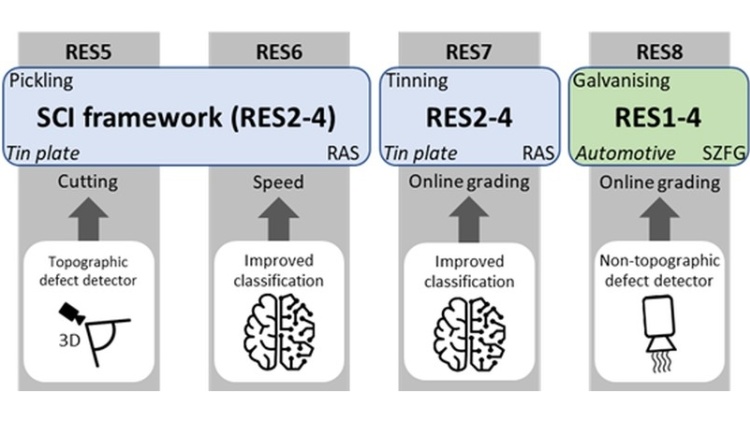

SufConInspect - Enabling zero-defect manufacturing for flat steel production by means of optimized inspection results and a new level of online surface quality control

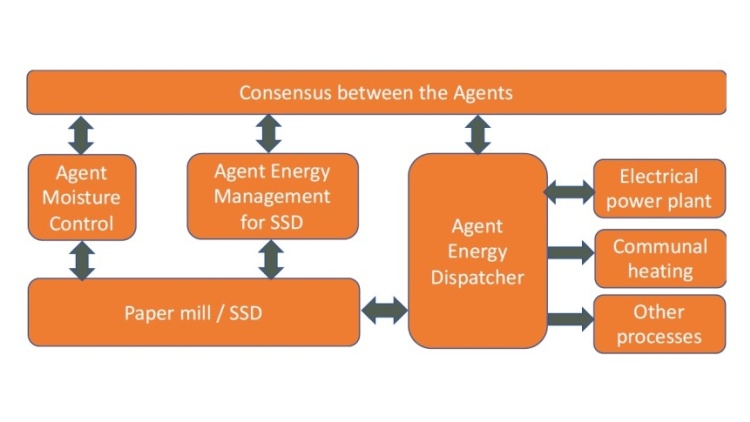

SteamDry - Superheated steam drying for sustainable and recyclable web-like materials

Your contact persons

2 Dr. Bernd Kleimt

+49 211 98492-385

bernd.kleimt_at_bfi.de

44 Colin Goffin

+49 211 98492 230

Colin.Goffin_at_bfi.de