Patents and licensing

Protecting innovations – sharing knowledge

VDEh Betriebsforschungsinstitut holds a large number of patents that underscore the innovative strength of our research institute. For decades, we have been developing innovative processing, measurement, analysis, and automation solutions for a wide range of technology fields in the steel and process industries.

Our developments are protected by patents both nationally and internationally. Even during the patent development phase, we actively seek cooperation partners in order to jointly develop and further advance products and markets.

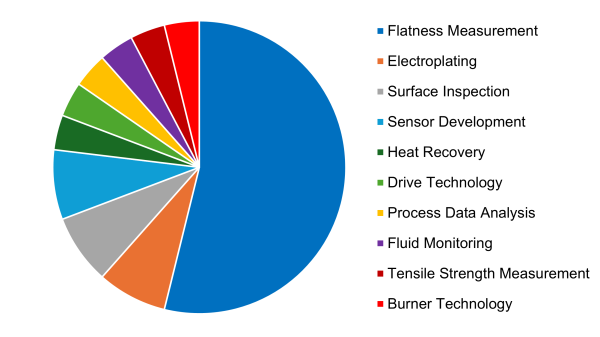

Focus areas of patent applications

Up to now, our patent applications have focused on the field of flatness measurement. In addition, we have active applications in numerous other technology areas.

Approaches to cooperation and licensing

We offer industry partners flexible cooperation and licensing models for our patents:

- Direct licensing of existing patents for industrial use

- Joint further development of patents into market-ready products

- Depending on the technology: exclusive or non-exclusive licensing rights

- Technology transfer and technical support by BFI experts

- Joint development and filing of patents

- Sale of existing patents

When is licensing of existing BFI patents possible?

Generally, we first file our solutions in Germany. The best time to get involved is during the nationalisation phase and the decision on whether to file a PCT or European patent, as well as the subsequent nationalisation or subsequent nationalisation, as you can decide on the scope of protection together with us.

Feel free to contact us.

Patents exploited and licensed to date

HR server:

During the production of flat steel products, modern measuring systems are increasingly capturing high-resolution quality and process data, which are stored coil-by-coil in plant-wide databases. However, to identify systematic issues, it is often necessary to analyse many coils simultaneously, which often involves virtually “rewinding” the data across several process steps.

With the cross-process-stage BFI HR Server, BFI has developed a patented solution that enables rapid access to high-resolution data and aggregates millions of quality and process values within seconds. This makes analyses that previously took weeks possible in near real time.

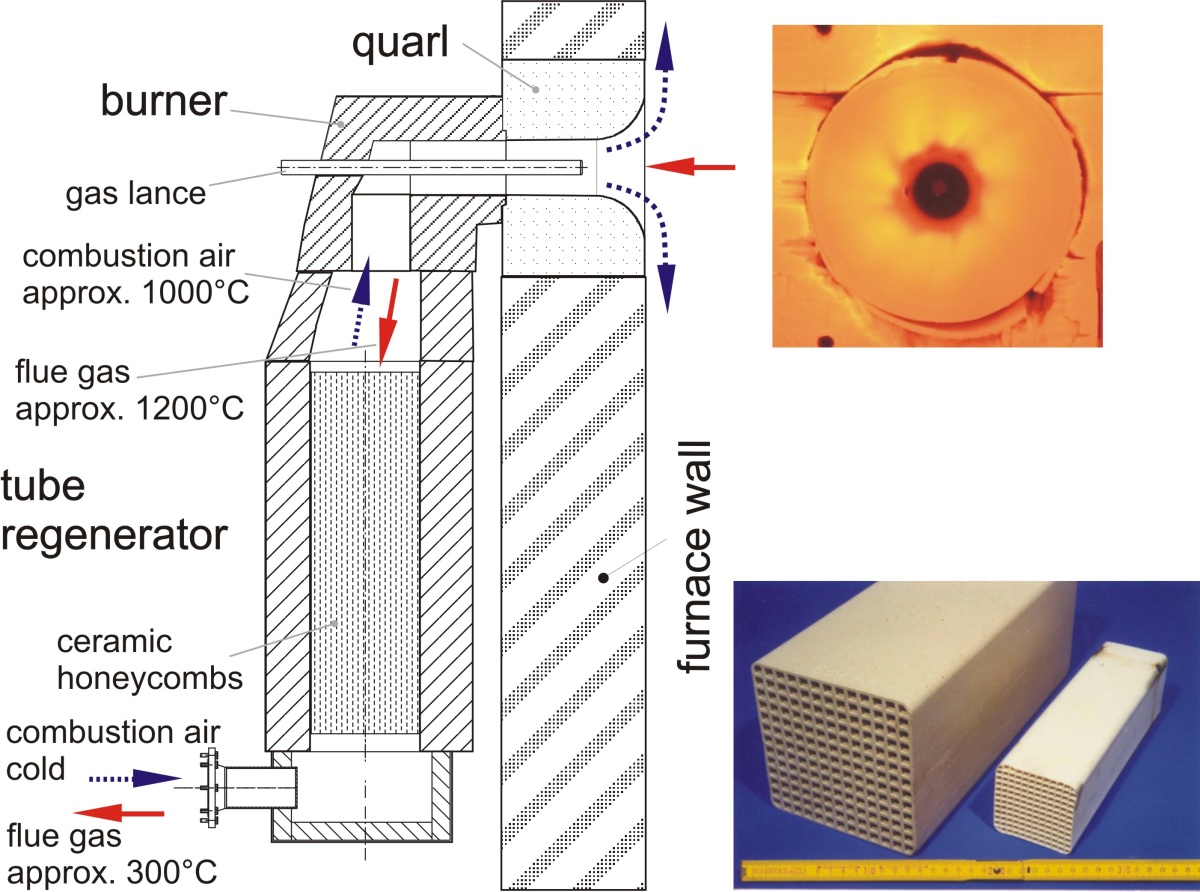

Flat flame burners & regenerative heat storage (ROREBS):

The ROREBS pipe regenerator burner system developed at BFI combines a thermal regenerator with a flat flame burner for exhaust gas temperatures up to 1350°C, with patent rights existing for each component.

The regenerator features ceramic honeycomb structures that are resistant to dust loading and can be installed either vertically or at an angle of up to 90°, ideal for side and ceiling burners. It was developed in collaboration with Buchwald & Kämper, who are also responsible for marketing.

The flat flame burner was developed in cooperation with Honeywell, who are co-owners of the patent and handle global sales. Together with Andritz Metals, both components have already been successfully implemented worldwide in batch furnaces for the steel industry.

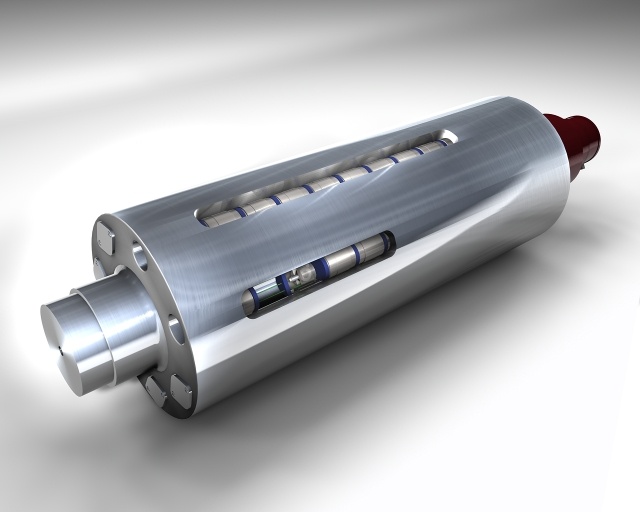

Axial measuring roll:

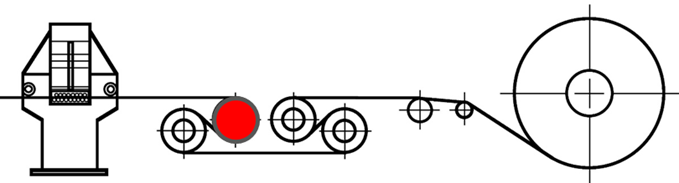

Developed and patented by BFI, the axial measuring roll is a flatness measuring roll for cold rolling mills and strip processing lines, which has been further developed and internationally marketed by licensees. It measures the flatness of metal strips made of steel, aluminium, copper, and other materials at the exit of the rolling mill, a crucial quality parameter that is directly used for process control.

For this purpose, force sensors integrated into the roll detect the radial forces exerted by the strip across the entire strip width onto the roll surface. The measured values are compared in real time with the target flatness and used for automatic control of the rolling process.

S measuring roll:

The S measuring roll is a variant of the BFI flatness measuring roll designed for the use in stretch-bend levelling lines. In this case, flatness is measured close to the levelling unit in the high-tension area, enabling the control system to react particularly quickly to changes.

The system is patented. In addition to the patent rights, BFI also provides the expertise for roll development as well as the appropriate control software.

Your contact person

44 Colin Goffin

+49 211 98492 230

Colin.Goffin_at_bfi.de