Circular Economy

The BFI provides comprehensive support to the steel and other process industries in their efforts to reduce resource consumption in production and in creation of added value from their liquid and solid by-products, residues, and process gases. The cross-sector approach is particularly important in this context. The BFI is therefore involved in the development and implementation of new processes and operating methods for resource-efficient material conversions and for the alternative use of solid and liquid by-products, residues, and process gases. The focus is on the following areas:

Dissemination of research results on the recycling of by-products in the steel sector

As part of the EU-funded international REUSteel project, the BFI has contributed to a collection of knowledge on the reuse and recycling of by-products in the steel industry. The impact of the results on sustainability and competitiveness was assessed, and the most promising and useful new lines of development as well as technological and non-technological barriers were identified.

Analytics and testing technology

The targeted recovery of valuable materials from waste and the increase in material efficiency require precise knowledge of the physical and chemical properties of the materials. BFI has a laboratory area equipped with state-of-the-art measurement technology for determining all relevant properties of liquid and solid media related to the production and processing of steel.

Separation and recovery of recyclable materials from liquid media

Established technologies for separating particles from cooling water, such as gravel and sand filters, produce a concentrate stream up to 5%–10% of the cooling water stream with low solid contents (<5 g/L), which must be dewatered with a high effort. As part of funded R&D projects (e.g. InspireWater), a magnetic separation process was developed at BFI as an alternative to gravel and sand filters. This process allows the separation of magnetisable particles and recyclable materials from liquid media such as cooling waters, emulsions, oils and polymer quenching baths. The amount of concentrate produced is 10 times lower than with conventional processes.

Two mobile plants are available for operational testing, one for treating volume flows of up to 5 m³/h and one for up to 50 m³/h. The technology is commercially available and is used very successfully in steelworks.

HYDROMETALLURGY

In cooperation with partners in the steel industry, the BFI developed a process for the chemical recycling of valuable materials such as titanium carbide from carbide processing (RecyTiC). The titanium carbides can thus be recycled with virtually no residue and returned to the manufacturing process. The transfer of the recovery process to tungsten carbides was investigated in the AIF-IGF project "Ultrasonic Reactor", which was funded by the Federal Ministry for Economic Affairs and Energy, among others.

Primary metal raw-materials are crucial to European industry, but are mainly imported into Europe. At the same time, Europe has large stocks of industrial by-products such as slag, which can contain significant concentrations of metals. The aim of the CHROMIC project was to recover chromium, vanadium, niobium, and molybdenum from carbon steel, stainless steel, and ferrochrome slag. Using microwave and conventional roasting combined with water leaching, >95% Cr and smaller amounts of V, Mo, and Nb (<10%) were recovered.

The transition of the iron and steel industry from carbon-based production (sintering plants, blast furnaces, oxygen blast furnaces) to hydrogen-based production (direct reduction, electric arc furnaces) will lead to a reduction in existing internal recycling routes via sintering plants and blast furnaces. One of the objectives of the TransZeroWaste project is the hydrometallurgical treatment of oil-containing sludge using suitable cleaning agents and the recovery of the deoiling agent by means of ceramic flat membranes to separate oil and solids.

The IGF research project ProEOS investigated measures to improve EOS quality in order to ensure its sustainable use. The research improved the control of slag quality, which improves marketability under new regulations. In the follow-up project ProEOSII, sustainable production and use of electric furnace slag from the steel manufacturing process was researched through metallurgical and processing measures in combination with a novel cooling water purification process.

Recycling of liquid media to increase resource efficiency

When treating liquid media such as cooling and gas scrubbing water and the respective process waters, recycling is the key approach to minimizing the use of fresh water. To achieve this, treatment processes are being newly developed or further refined so that dissolved salts such as chloride, sulphate, or nitrate are separated and other components such as cyanide or organic matter are converted.

Selective removal of divalent ions with NANOFILTRATION

Separating monovalent and divalent ions during wastewater treatment is advantageous for water softening and salt concentrates recycling. The BFI uses filtration technology in subsidized R&D projects (WEISS, IndiWater, MiningWater, ZHyRON), among other things.

Two different systems are available at the BFI for nanofiltration experiments on a laboratory, technical, and pilot scale: a high-pressure dead-end filtration system for membrane selection and a BFI pilot system for cross-flow filtration.

Two different systems are available at the BFI for nanofiltration experiments on a laboratory, technical, and pilot scale: a high-pressure dead-end filtration system for membrane selection and a BFI pilot system for cross-flow filtration.

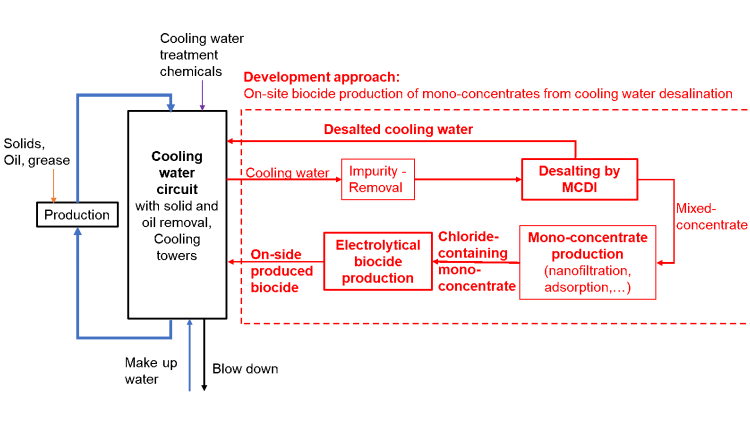

Customised desalination through membrane-based deionisation

Membrane-assisted capacitive deionisation (MCDI) was further developed as an alternative desalination process and used for the treatment of industrial water. Experience with the use of MCDI already exists in the cooling water sector (WEISS4PN, SPOTVIEW). This achieves water recovery of around 75% and chloride removal of up to 90%. The energy demand is 0.8 to 1.1 kWh/m³. Other current areas of application in the steel industry include the desalination of gas scrubbing water and wastewater (IndiWater, ZHyRON) and water recovery from mining wastewater, for example in phosphate mining (MiningWater).

Wastewater recycling using membrane distillation

Water treatment using membrane distillation (MD) is a thermally driven separation method. BFI R&D work in the EU-funded CORNERSTONE project addresses the extraction of heat from the gas scrubbing water (approx. 82 °C) of an iron ore direct reduction plant. This heat powers an MD plant, in which gas scrubbing water is treated after separation of particulate matter. Furthermore, MD technology is used for the desalination of wastewater in the EU project ZHyRON. The suitability of the MD process in combination with diffusion dialysis was investigated for the recovery of acids and metals from pickling solutions using combined membrane processes (ReWaCEM).

Removal of suspended compounds

The basis for ensuring efficient and stable desalination is the reliable removal of suspended solids (particles, biomass) and organic compounds (emulsified, such as oil and grease) prior to the desalination of cooling water and wastewater. This has been successfully demonstrated in R&D projects (MiningWater, Indiwater) through the use of vacuum filtration with ceramic flat membranes (plant technology from Cerafiltec, Germany). The modular system allows to create water treatment plants of any size. Two filtration plants are available at BFI: a laboratory plant with a membrane area of 0.01 m² (flow rate: 0.3 - 15 l/h) and a pilot plant with 3 modules with a membrane area of 18 m² for a maximum flow rate of 9 m³/h.

Utilisation of desalination concentrates via the production of monoconcentrates

Chloride-containing monoconcentrates produced in desalination plants (e.g., MCDI) can be used to manufacture biocides. For this purpose, a pilot plant for electrolytic biocide production with an anolyte volume flow of up to 16 L/h was used in the AiF-IGF research project KonzentratBiozid, which was funded by the Federal Ministry for Economic Affairs and Energy. In addition, sulfate-based monoconcentrates can be used as raw materials, e.g., in the construction industry.

Removal of heavy metals

In order to enable the recycling of industrial process water, dissolved heavy metals must be removed from high-salt wastewater, such as cooling and washing water. Adsorption offers an effective method for the selective removal of heavy metals at low concentrations. However, existing adsorbents are often too expensive and not suitable for the specific requirements of industrial wastewater. Therefore, the AiF-ZIM research project "Schwermetall-Adsorber" developed a cost-effective iron hydroxide-based adsorbent specifically designed for wastewater containing solids and salts. This new adsorbent and the associated processes were tested in suspension reactors and fixed beds to ensure the efficiency and cost-effectiveness of heavy metal removal.

Improving energy efficiency in industrial water cycles

The EU-funded WaterWatt research project aimed to remove market barriers to energy-efficient solutions in cooling and process water circuits and to create basic knowledge about energy management and savings potential. The objectives were achieved through: i) case studies in relevant industries, ii) development of improvement measures for energy efficiency in industrial water cycles, iii) market studies, iv) capacity-building activities, and v) dissemination in workshops and through e-learning.

An energy efficiency assessment platform (E3 platform) was developed to disseminate knowledge/expertise on energy efficiency improvements through games.

Processing of solid raw materials, by-products, and residual materials

The recycling of solid raw materials, by-products, and residual materials usually requires upstream processing. This involves adjusting the desired material properties for the subsequent recycling process, e.g., by crushing, classification, sorting, drying, de-oiling, agglomeration, or thermal pretreatment. BFI has many years of experience and various pilot plants for such processing, such as magnetic separation, crushing, grinding, screening, pelletizing, and granulating equipment, as well as briquetting presses.

Processing of ferrous materials for reuse in the direct reduction route

The transition to hydrogen-based steel production based on direct reduction will cut off the current internal recycling routes for ferrous materials produced during iron and steel production via sintering plants and blast furnaces. In the international TransZeroWaste project, the BFI is focusing on the resource-efficient processing and agglomeration of iron-containing materials, such as low-grade iron ores, oil-containing scale, and other materials, as a mandatory step prior to metallurgical reuse in the direct reduction route. In addition to the hydrometallurgical treatment described above for removing disruptive contaminants such as oils and fats, two further approaches were investigated as low-CO2 processing methods: cold pelletizing and briquetting, and hot pelletizing with microwaves.

In cold pelletizing and briquetting, the BFI is conducting laboratory tests on representative metallurgic residues to develop optimized formulations with innovative binders to achieve the best possible strength. De-oiled or degreased materials are also being investigated after appropriate pretreatment. The results obtained here are being validated by international partners on a pilot scale.

In hot pelletisation, the microwaves couple directly to the molecules, crystals, or cluster structures of the materials, and the energy can be used almost entirely for material heating and activation energy, so that only a little residual heat is transferred to the system (cool kiln). This has already been successfully tested in a pilot plant in the predecessor project DESTINY. To ensure proper implementation, TransZeroWaste will incorporate new validated concepts for the configuration of microwave ovens, material preparation, and control systems in order to industrialise microwave heating as a solution for highly energy-efficient processes.

The PSP-BOF project investigated the removal of phosphorus from converter slag. Topics include the development of a new cooling strategy for converter slag, the mechanical separation of the treated slag into a P-poor & Fe-rich and Fe-poor & P-rich slag fraction, and investigations into transfer to an industrial scale. The result is the separation of phosphorus from BOF slag and its use as fertilizer for agriculture and agricultural production, while the remaining slag can be used through internal recycling via sintering plants/blast furnaces.

As part of the follow-up project SlagReus, a process chain was developed at BFI using magnetic separation methods and suitable crushing and microwave technology to fractionate steel mill slag into a phosphorus-rich fraction for the fertilizer sector and an iron-rich fraction for recycling in metallurgical processes.

Metallurgical processes for metal recovery or slag conditioning

The BFI uses self-reducing agglomerates in shaft furnaces and electric arc furnaces to recover iron and alloying elements from metallurgical residues. Furthermore, BFI has extensive expertise in zinc recovery from zinc-containing dusts, including melt bath injection (SchmelzInjekt), as well as in the recovery of valuable alloying elements such as chromium in the production of high-alloy steels. The latter is achieved by reducing the liquid slag in the electric arc furnace, whereby fine-grained reducing agents are pneumatically injected into the melt (EPOSS). BFI has several injection facilities available for operational trials.

In the DRI smelter project funded by the state of North Rhine-Westphalia, in addition to investigating and optimizing the smelting of sponge iron from hydrogen-based direct reduction, another focus is on the targeted adjustment of slag composition through suitable processes and the addition of appropriate additives. The product slag from the smelter shall be used as a raw material for cement production, similar to blast furnace slag. Another aspect is the investigation of the recycling of iron-containing metallurgical residues.

In the InSGeP project, the BFI is part of an international consortium investigating slags produced during next-generation steel production in Europe. This project is developing guidelines for the use of new slags from future steel production. The project is based, among other things, on slag samples produced in laboratory, pilot, and industrial-scale trials. The slag is treated with various cooling and granulation processes and evaluated on the basis of chemical, mineralogical, ecological, and physical properties in order to obtain the physical properties and environmentally compatible products required for various applications. The use of slag in applications such as road construction, cement/concrete, or 3D printing is being tested.

Use of alternative and biogenic carbon carriers and upgrading of carbon-containing residues

In connection with the metallurgical recycling of residues, carbon carriers will continue to be needed in the future, but their use must be CO2-emission neutral.

In the SCI4Climate2.0 project funded by the state of North Rhine-Westphalia, the BFI quantifies the remaining carbon usage required in future hydrogen-based steel production and evaluates the corresponding potential for the use of bio-carbon or biomass.

The BFI has extensive experience in the production and operational use of carbon agglomerates or mixtures from alternative or biogenic carbon carriers that enable corresponding CO2 emission savings (INNOCARB).

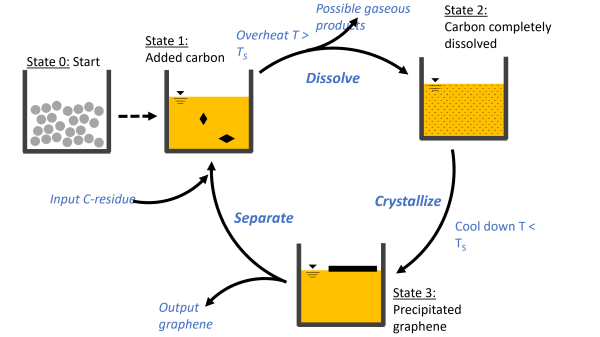

In addition, the BFI is currently developing a pilot-scale process for upgrading carbon-containing residues through recrystallization from molten metal (RekCarb; RekCarb2). For this purpose, melt recrystallization is carried out in a mini-plant to produce graphene nanoplatelets (GNP) in continuous operation. The use of inductive heating technology (medium frequency) enables continuous cyclic operation. The quality of the graphene produced is evaluated using Raman spectrometry, among other methods. The establishment of a reliable mass and energy balance serves as the basis for estimating the costs and effort involved in production operations. The application of GNP is being tested, for example, in cement mixtures and conductive dispersions.

Simulation calculations and modelling for process optimisation

Within the scope of all the above-mentioned topics, forecasts regarding the quality of the products manufactured and the resource requirements are important, as is the optimization of product-specific resource consumption. These are carried out by the BFI using thermochemical calculations or flow sheet modelling based on the HSC Chemistry® or FactSage® software tools. These tools are used, for example, in the projects Schmelzinjekt2, DRI-smelter and InSGeP.

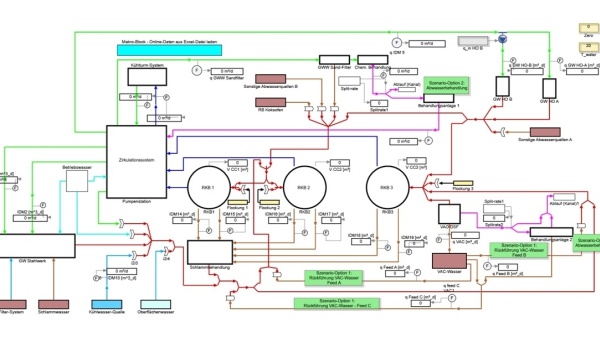

Furthermore, the BFI uses the commercial software tool SIMBA#® for modelling and simulation of issues in cooling and process water cycles in various funded R&D projects (WEISS4PN, IndiWater, CORNERSTONE, DynaWater4.0) and bilateral projects. The digital mapping of process water cycles enables forecasts to be made regarding process water, chemical, and energy requirements, process and resource optimization, the avoidance of downtime and bottlenecks, optimal planning of maintenance measures, and the digital testing of new process water treatment plants prior to operational implementation.

Measurement techniques for process monitoring and optimisation

Acid process baths for surface treatment

In collaboration with partners in various R&D projects, BFI has developed a model-based measurement technology (DynAcid®) for the continuous and simultaneous monitoring of acid and metal salt concentrations in process baths used for surface treatment in the steel and metalworking industries. The measurement technology is being used successfully in industrial treatment plants (currently available for the following acid system applications: HCl-Fe, H2SO2-Fe, HF-HNO3-metals, HNO3-H2SO4-Zn, H2SO4-Zn).

Atline measurement of zinc concentration in process water and sludge

In collaboration with partners, BFI is currently developing an atline analysis technique (analysis frequency 15 minutes) for measuring zinc concentration in process water and sludge in the AiF-IGF project ZinkAtline, which is funded by the Federal Ministry for Economic Affairs and Energy.

Solid measurement in process water

As part of an AiF-IGF project (FKZ 18673N) funded by the Federal Ministry for Economic Affairs and Energy, a solids sensor was developed that can be used for all relevant process water and concentration ranges (1–100,000 mg/L) in steel production and metal processing. The patented (DE102017006676B4) solids sensor is based on particle detection by a magnet with subsequent quantification of the coating using a load cell. This selective measuring principle makes the sensor insensitive to typical interference factors such as abrasion, salts, oils, low light transmission, and deposits. The solid matter measurement technology (MAGS) was successfully used as part of the EU RFCS project DuMiCo to monitor dust discharge from the blast furnace and thus to evaluate the operating status in real time. Furthermore, it can be used to monitor limit values for wastewater discharge and, for example, cooling water quality in the hot rolling process. This allows product quality to be maintained and maintenance costs to be reduced.

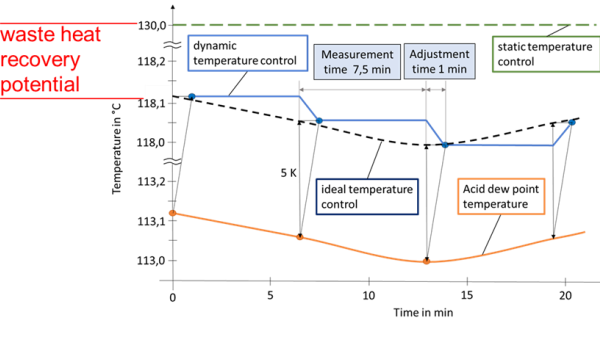

Acid dew point sensor for dynamic waste heat recovery from steel mill exhaust gases

The acid dew point temperature fluctuates greatly during the combustion of steel mill gases. To prevent corrosion damage, the exhaust gas temperature is usually set 10–20 K above the calculated maximum acid dew point temperature (ADP). This, however, causes energy losses at lower ADP temperatures. The RFCS project SafeDewPoint demonstrated that up to 20% of waste heat can be recovered by dynamically adjusting the exhaust gas temperature. A novel inline acid dew point sensor was developed and successfully tested for this purpose.

Online determination of slag basicity and viscosity

In order to determine slag properties more rapidly during the ongoing process, to optimize slag handling, and to identify deviations from the planned process sequence, BFI investigates new measurement methods and models for determination of current slag properties. The new measurement methods developed in the iSlag project include impedance probes for determining the chemical composition and basicity of slag in ladle furnaces and electric arc furnaces. In addition, a camera-based image processing system was developed in combination with an online slag balance model to estimate slag viscosity during the purging process in ladle furnaces. Both systems provide information about slag properties that is used by decision support systems to assist operators and plant managers in optimizing slag properties in terms of process technology and for optimal slag recycling within and outside the steel production cycle.

Characterisation of steel scrap and optimisation of the scrap mix

The use of steel scrap as feedstock makes a significant contribution to the circular economy in steel production. To characterise the variable properties of steel scrap, the BFI has developed web-based software that uses statistical calculations to determine the metal yield, composition, and melting energy requirements of different types of scrap based on the process data that is usually available (see REVaMP, s-X-AIPI). Cost- and quality-based optimization of the scrap mix uses the current results of scrap characterization.

Furthermore, various measurement methods for characterizing steel scrap are being developed at BFI. In REDERS, hyperspectral cameras are used to analyse the recycled material on a conveyor belt at the exit of a shredder plant in order to determine the proportion of scrap pieces containing nonferrous metals (Cu, Cr…) and organic components. In DigreeS, a combination of laser analysis (LIBS) and image processing is used to analyse the scrap load of a truck at the entrance to the steel mill. In REVaMP, neutron sensors and LIBS sensors were tested in collaboration with other research partners for the in-line analysis of steel scrap.

Projects on this topic

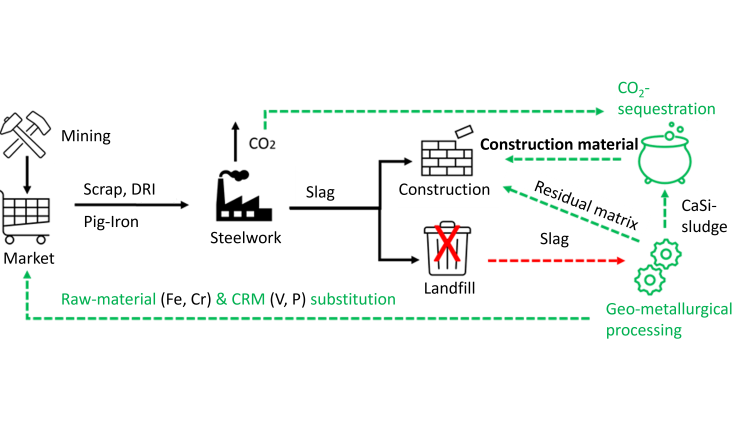

GeoCRM - Geometallurgical processing of steelmaking slag for recycling critical raw materials and CO2 binding

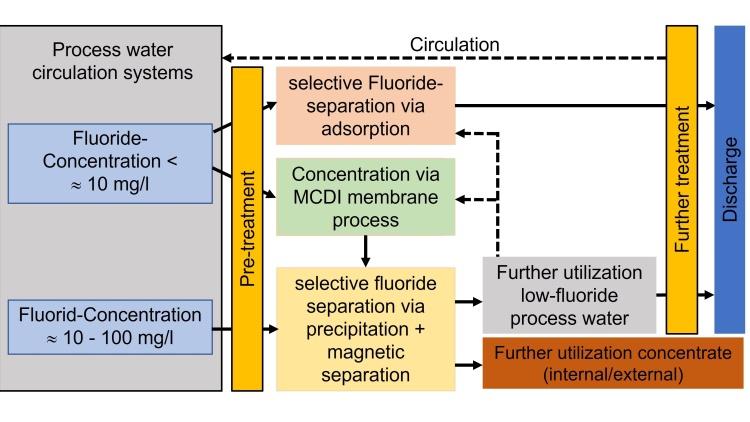

FluoridSelektiv - Process development for selective fluoride separation from industrial process water

ZinkAtline - Development of an atline measuring method for rapid analysis of the total zinc content in process water

Konzentrat-Biozid - Development of a reliable process for cooling water desalination based on membrane-assisted capacitive deionization with production of monoconcentrates

Your contact persons

23 Dr.-Ing. Matthias Werner

+49 211 98492-539

matthias.werner_at_bfi.de

30 Dipl.-Ing. Gerald Stubbe

+49 211 98492-969

gerald.stubbe_at_bfi.de