Operational campaigns

The BFI conducts measurements and investigations on industrial plants within the scope of contract research and funded research. This involves the use of special measurement technology and mobile test facilities that are connected directly to the operating plants or operated in bypass mode.

- Determination of the composition and volume flow distribution of typical liquid media such as cooling water, emulsions, acids, process water, and gas scrubbing water

- 1 MW pilot plant with process and metallurgical gases from the plant network

- Exhaust air/gas: Temperature, velocity, pressure, humidity, gas composition using process gas analyzers, mass spectrometers, and FTIR, calorific value, minimum air requirement, density, Wobbe index, dew point

- Smoke and dust: Dust/fine dust content, flow visualization using artificial smoke, smoke propagation with velocity determination (structural PIV)

- Vibration diagnostics assessment of machines and systems to evaluate the process status and optimize wear behavior

- Video periscope measurements in the high-temperature range for optical inspection of components in the furnace

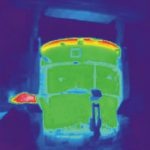

- Area measurement of surface temperature using thermography, also as long-term campaigns with image evaluation

- Determination of the thermal condition of the refractory material of ladles using thermography and thermocouple instrumentation

- Measurement of the melting temperature and recording of the cooling curves to determine the microstructure and chemical composition

- Continuous measurement of the liquid steel temperature with DynTemp®, e.g., to optimize the homogenization time and the timing of the thermocouple measurement

- Recording of operational measurements for the creation of energy and material balances; comparison between normal and BFI-adjusted operating mode

- Process observation and evaluation of ladle treatment with regard to rinsing efficiency in order to ensure treatment success (homogenization, degassing, inclusion separation)

- Monitoring of slag removal during liquid steel production using IR cameras and image processing to minimize residual slag in the ladle and steel losses

- Development of customer-specific solutions for automatic process control using image processing, e.g., level detection

- Observation of the casting powder cover in continuous casting molds for permanent operator support and as a campaign during casting powder conversion and tests

- Injection tests in melting and shaft furnaces to test alternative fuels, reducing agents, and additives for process control and adjustment of required product qualities

- Application tests of agglomerates (pellets, briquettes) as alternative feedstocks for melting and shaft furnaces

- Investigation of gas separation and conversion processes in the bypass of process gases (membranes, adsorbents, catalysts)

Test and pilot plants: Resource Technology Liquid Media

Plant | Task | Parameter |

|---|---|---|

Laboratory plant: | for all media: e.g. HCl-, H2SO4 and mixed acids | V= 250 ml |

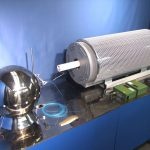

Cross-flow micro/ultrafiltration | Acids, alkalis, Waste water | V = 8 – 15 l |

Microfiltration pilot plant | Solids separation (e.g. silicon, sludge) | VFeed = 5000 l/h |

Ultrafiltration pilot plant | Degreasing bath care, Oil separation | VFeed = 4000 l/h |

NF/RO membrane filtration Plant | Acid and metal recovery (e.g. for mixed acids) | VFeed = 1500 l/h |

Membrane contactor | Metal recovery (e.g. phosphate coating) | Vmax = 1000 l/h, V = 120 l |

Mixer-Settler Laboratory/Technical Plants | Metal recovery (waste water treatment) | Lab: V = 2 x 3 l (Glas) |

Concentration monitoring: | HCl- u. H2SO4-Pickling acids | V = 50 l |

Test and pilot plants:

Resource technology solid and gaseous media

Plant | Task | Parameter |

|---|---|---|

Thermogravimetry | Characterisation of thermal solid reactions under variably adjustable thermal conditions and gas mixtures | Shaft furnace with scales and online gas analysis |

Sticking/Clustering/RUL | Examination of larger sample quantities (up to 2 kg) under variably adjustable thermal conditions and gas mixtures, and, if necessary, under application of mechanical load | Shaft furnace with online gas analysis and load application |

Palletising plate (laboratory) | Agglomeration of input materials or residual materials; selection of suitable binding agents; subsequent characterisation of the pellets produced | Diameter: 400 mm |

Extrusion press and stamp press (technical centre); tablet press (laboratory) | Press agglomeration; including briquetting of alloying agents, carbonaceous and metal-containing dusts and sludges | Various briquette shapes, e.g. hexagonal base, wrench size: 100 mm; material length: up to 120 mm; or 60x40x40 mm |

Ball mill, Disc swing mill (laboratory) | Grindability with determination of Blaine value | Grinding drum: up to 43 l; Charge volume max. 20 l |

Intensive mixer (technical centre) | Mixing or granulation of feedstock and residues | Mixing vessel: 5 l resp. 10 l |

Drum magnetic separator with permanent magnet system (technical centre) | Magnetic separation | Wet and dry; Particle size up to 20 mm; Throughput max. 1000 kg/h; Rotational speed of drum: 10-150/min; magnetic flux density: 0,45 T |

Davis Tube (laboratory) | Magnetic separation | Magnetic flux density up to 1,5 T |

Pneumatic conveying and dosing equipment (operational scale) | Injection of powdered substances into a melt bath, shaft furnace or other thermal processes | Pressure vessel conveying plant 0,5 m³ and rotor conveyor system: Mass flow depending on conveyed material: 10-150 kg/min |

High-frequency and medium-frequency generators for inductive heating | Technical trials for melting metal or targeted heating of quartz glass tube reactors | 1 x 10 kW; 2x 25 kW; up to 1 MHz; Quartz glass reactor tube with around 80 mm diameter, up to 1200°C |

High-temperature melting furnaces (resistance heated) | Technical trials for melting slag or metal | Max. 1700 °C; Crucible diameter up to 100 mm resp. 250 mm |

Muffle furnace (laboratory) | calcination loss | Temperature max. 1300°C |

Dust measurement (in industrial plants) | Gravimetric and isokinetic determination of dust concentration in exhaust gas or exhaust air flows | Extensive range of measuring probes, filters and accessories for various operating conditions |

Measuring Technology

Name | Picture | Application | Technical details |

|---|---|---|---|

Thermal camera |

| Determination of thermal condition and process optimization, e.g. of ladles, processes, etc. | T up to 2000°C |

DynTemp |

| Continuous melt temperature measurement for process optimization | T 1500 - 1700°C, 2K Measurement precision |

Furnaces, high temperature furnaces |

| Temperature treatment and calibration up to 1600 °C | T up to 1600°C |

Fiber optic sensor technology |

| distributed temperature measurement at production aggregates (mold, refractory,...) | T up tp 600°C, up to 0 sensors per fiber, 4 fibers per interrogator |

RFID (High Temperature) |

| Equipment for reading ID, e.g. from steel mill ladles, consisting of ID tag, readout unit and antennas | Maximum Operating temperature up to 350°C, range up to 5m, frequency range 2.4 GHz |

Data Logger | Recording of process data such as temperature values from thermocouples to know and optimise the thermal condition, e.g. of ladle wall and bottom | 10 Channels, 130.000 Measured data, max. operating temperature 110 °C | |

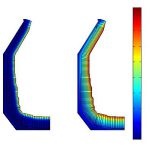

FEM Software |

| Calculation of temperatures, stresses and flows using the finite element method | customized |

Image processing |

| Development of customised solutions for automatic process control, combination of camera systems (VIS and IR) with online or offline image processing | customized |

Laser vibrometer | Investigation of the process behavior and the load of plants and plant components | Frequency up to 25 MHz, Max. Working distance up to 250m | |

mechanical workshop |

| Design and manufacture of individual solutions, e.g. protective housings for measurement technology, adaptations to existing systems | turning, milling, drilling, sawing, welding, sheet metal working |