Optical diameter and length measurement

In virtually all areas of forged material manufacturing plants, there is a high demand for continuous measurement of the dimensions of the product during production. Of great importance here is the instantaneous, non-contact measurement with a high continuous measurement rate, in contrast to the random individual measurement of the finished product, which is often dangerous for the employees.

For this reason, a measuring system is used that uses the intrinsic radiation of the hot material to determine the diameter. This enables reliable and economical monitoring of the production steps. Diode line cameras serve as sensors, which use the image of the hot material generated by its own radiation for signal processing.

Our solution:

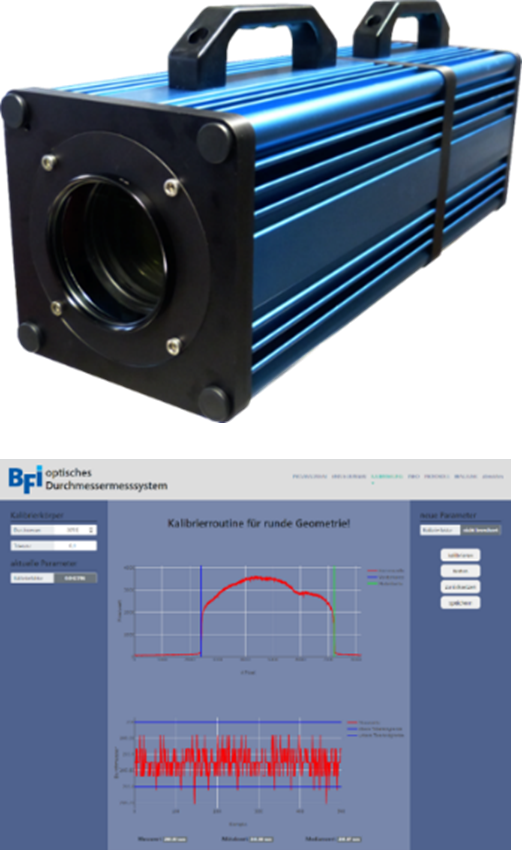

For more than 30 years, BFI has been developing tailor-made solutions for non-contact optical diameter and length measurement. The sensor technology is housed in a sturdy, industrial-grade aluminum housing and captures not only round material but also rectangular formats. The measuring system can be used at material temperatures above about 600 °C. With a backlighting material temperatures < 600°C are also possible. It is maintenance-free and usually does not require any cooling or flushing media. The distance between the camera and the material can be up to 15 m.

The resolution is ± 1/2000 of the field of view, and the measurement results are continuously displayed at 50 Hz output frequency via web interface-based software.

BFI supports the introduction of the measuring system from performance of a feasibility analysis up to the integration at the respective unit.

Further Information: Download Flyer

Your contact person

44 Colin Goffin

+49 211 98492 230

Colin.Goffin_at_bfi.de