Process Optimisation

The process optimisation in the steel industry is aimed at more efficient processes, better use of resources and cost reduction. Both individual processes and entire process chains are optimised in order to increase efficiency, safety, production and quality as well as reduce costs and emissions. In the area of steel production, these measures encompass the entire production route, from the production of pig iron and crude steel through to the finished product.

The topic of process optimisation is closely linked to the topics of "digitisation and process measurement" and "CO2 reduction ans energy efficiency".

Digitalisation with sensor technology, data analysis and AI can be used to monitor, control and further optimise processes in real time in order to minimise energy consumption and the use of fossil fuels. To date, however, the digitalisation of complex production processes in industrial practice is still quite limited, often due to a lack of measurement data on local conditions and a lack of understanding of error mechanisms. New measurement techniques and models then enable a much deeper process analysis and the development of practical measures. The combination of process optimisation and digitalisation thus opens up the path to a sustainable future for industry. Some examples are listed below.

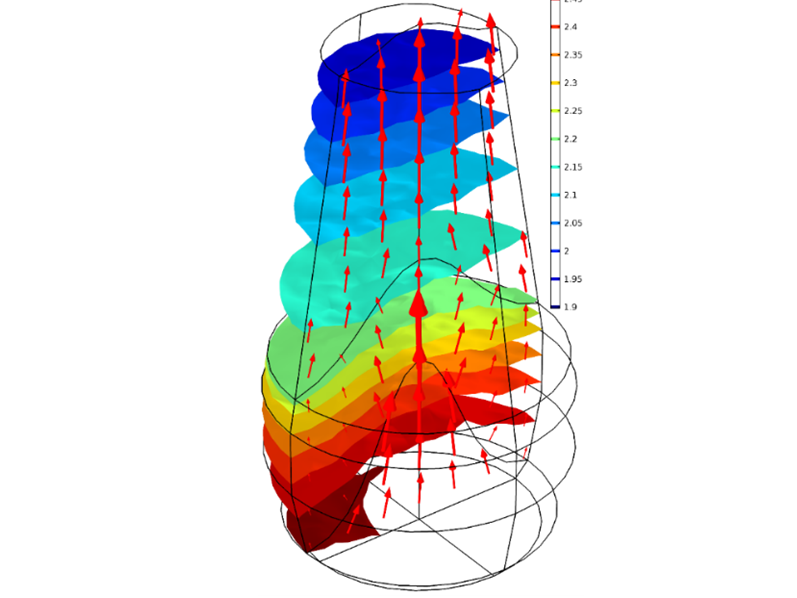

Process optimisation in pig iron production with the aid of simulation models

The optimisation of raw iron production can benefit significantly from the use of modern simulation models. These digital tools make it possible to simulate the processes in the steel plant in as much detail as possible and to validate various operating strategies in advance.

Despite numerous measuring points, the essential internal process conditions in raw iron production cannot usually be measured directly. In order to enable process optimisation nevertheless, the BFI links complex simulation models with operational databases using plausibility and optimisation algorithms. In such online applications, the models serve as ‘soft sensors’ and as part of digital monitoring tools, also offer the possibility of recognising potential malfunctions or inefficiencies at an early stage.

This allows targeted measures to be developed in order to avoid failures, increase process stability and plant safety and reduce emissions and costs. For example, the BFI has already created some globally unique applications for use in blast furnaces. (StackMonitor, DuMiCo, H2TransBF)

These are currently being further developed for operation with hydrogen enrichment for blast furnaces and direct reduction shaft furnaces. (H2TransBF, H2II, MaxH2DR). Simulation models can thus become a key tool for the future-oriented design of plant technology in the steel industry, particularly for energy-intensive and complex high-temperature processes.

Process optimisation with statistical and AI methods using online tools

Process optimisation in the steel industry can be significantly improved by combining physical-statistical models and AI methods. Statistical models that also take into account the physical fundamentals of the process are useful, for example, for monitoring the filling level and avoiding the ‘dead man’ effect in blast furnaces or for predicting oxidation processes and deriving material and quality losses from the reheating furnace to the cooling bed in the hot rolling process (CAPRI, ReduHeatLoss). Online tools from the BFI enable the implementation of these technologies to support daily operational management in real time for various aspects, resulting in more efficient monitoring and risk assessment.

This often involves a combination of statistics, physics and empirical knowledge. This is used, for example, in a system for preventing blow mould damage and for detecting faulty process conditions in the blast furnace shaft.

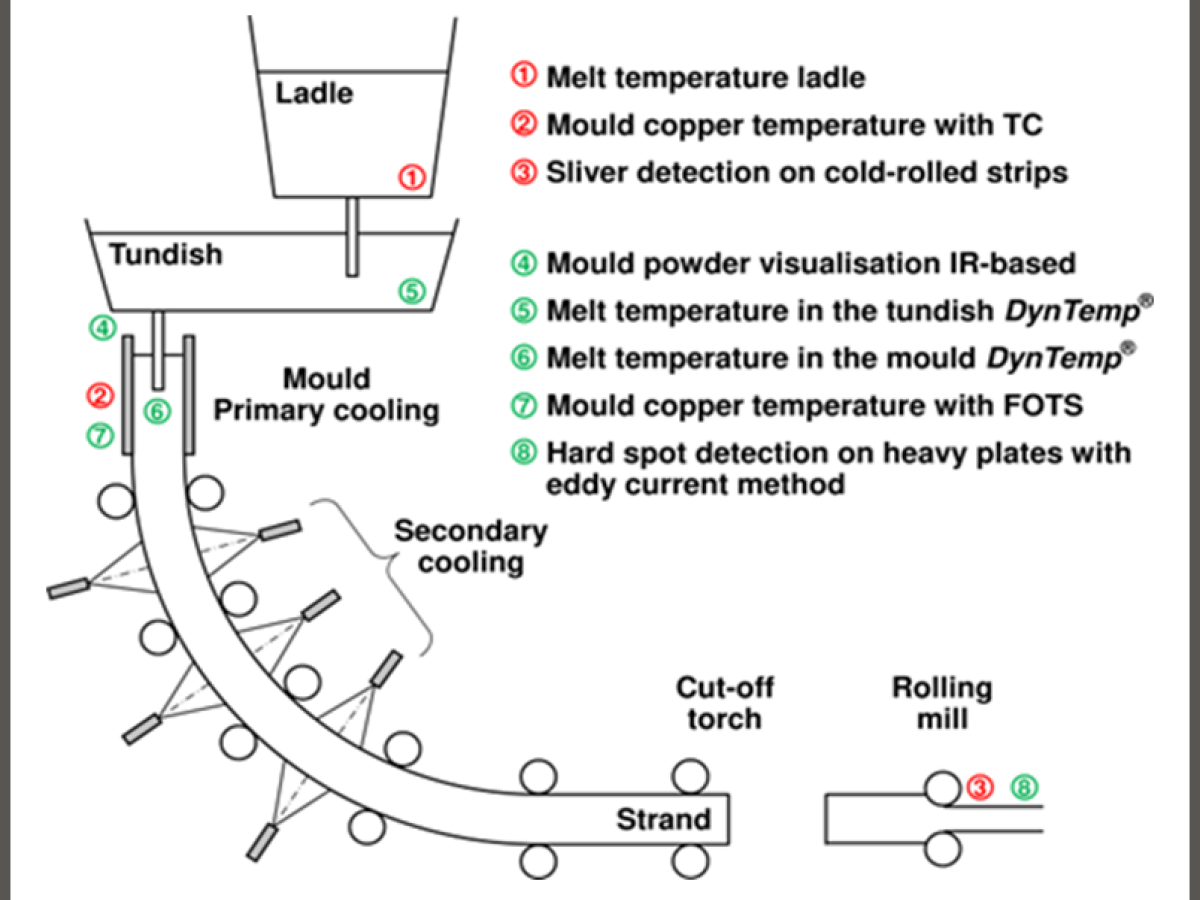

Optimisation of the continuous casting mould

As the conditions in continuous casting moulds are important for product quality but are not precisely known, these were the aim of the RFCS project ‘Embedded real-time analysis of continuous casting for machine-supported quality optimisation’ (RealTimeCastSupport). New measuring systems (fibre-optic and camera-based) were established.

Conventional and new data were analysed and a digital twin was developed. The results were implemented in an assistance system that provides suggestions for optimisation in real time. The successful work will be continued in other research projects that have already been approved. (SunShine). The expertise will be disseminated further in dissemination projects (e.g. METACAST).

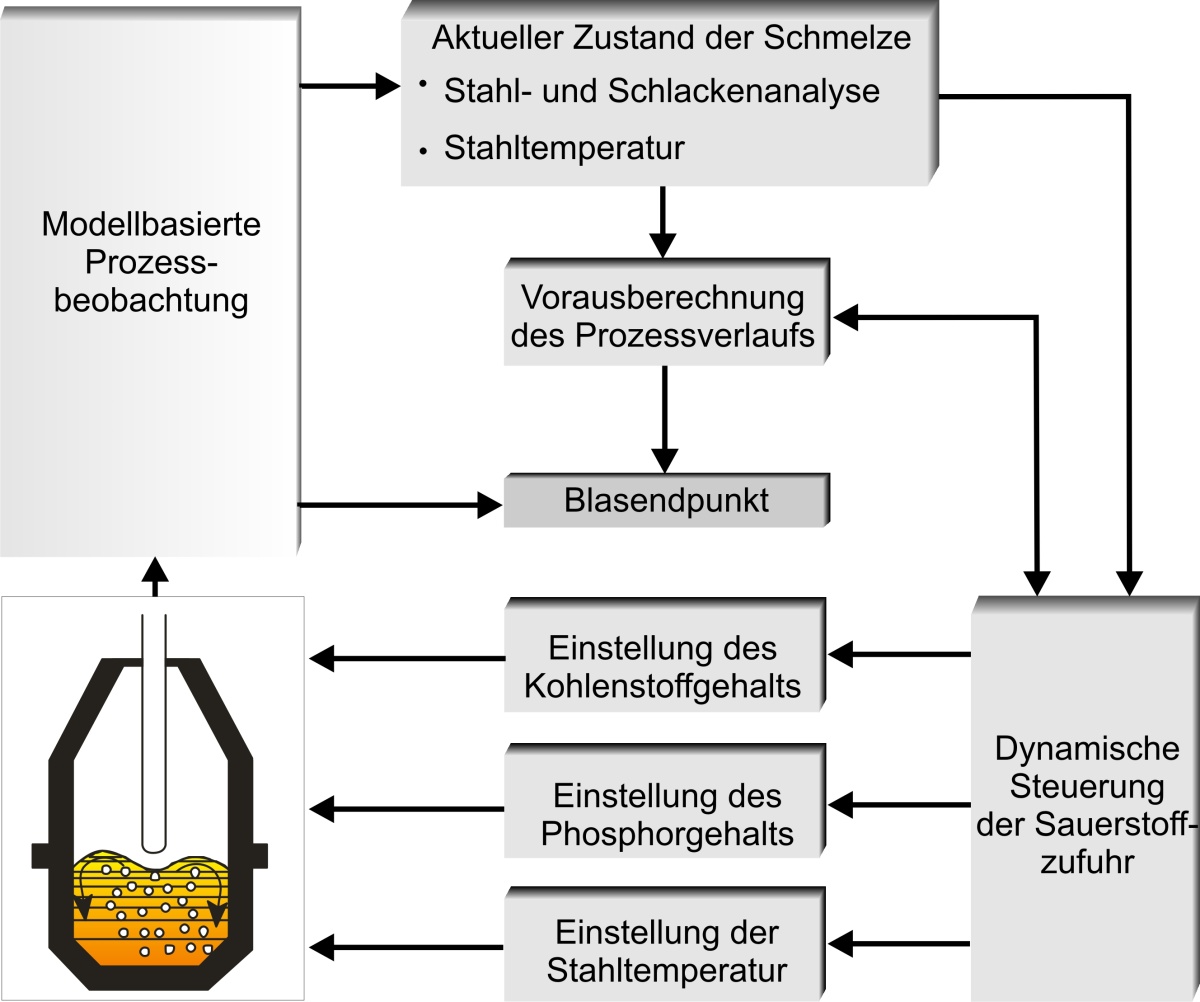

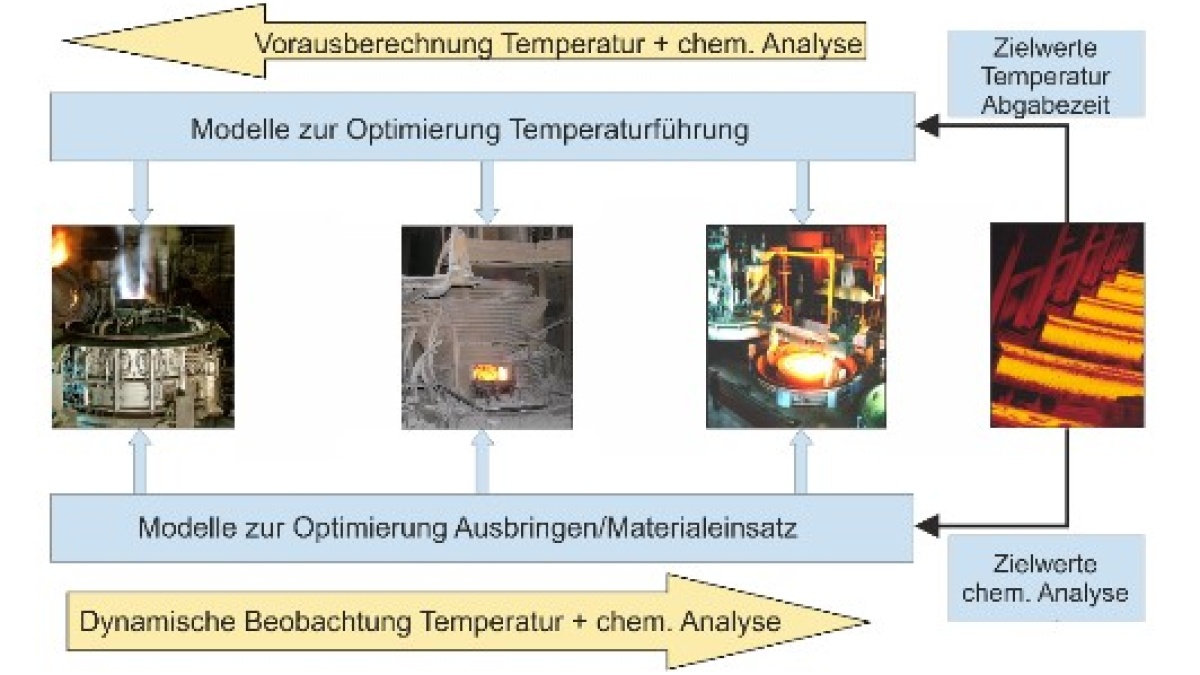

Process optimisation and quality monitoring

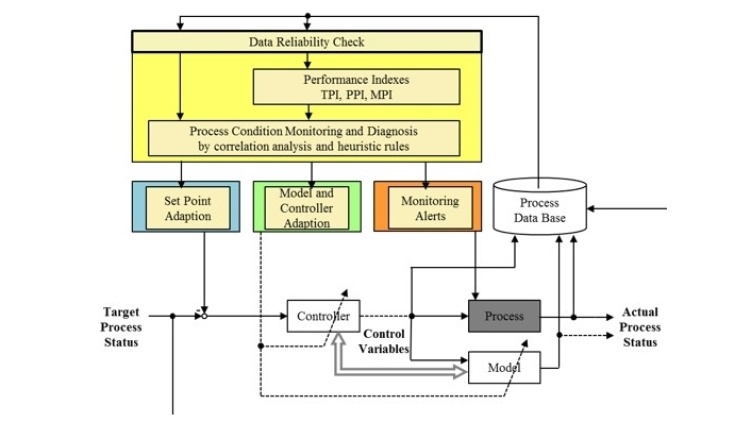

To optimise the process of liquid steel production, the current process status is monitored online using a model and non-continuously measurable process variables are calculated. Furthermore, the process is controlled or regulated by specifying model-based calculated target values (see BOFdePhos for the blow steel converter and REVaMP for the electric arc furnace). In this way, the process engineering targets can be achieved while minimising the consumption of energy, input materials and resources.

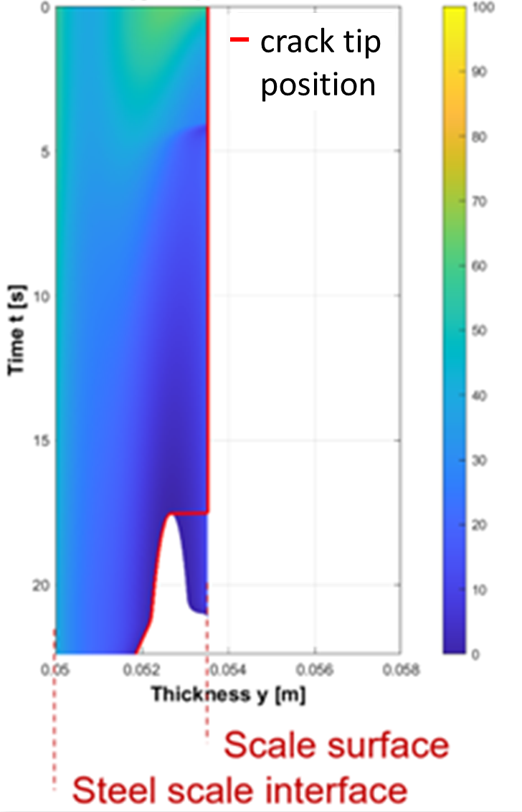

From hot forming to the finished product, process data is used to calculate for example, heat transport and transformation processes in the product or scale formation on the product in real time using physical models. From this, the operator can derive material losses, surface quality and stress states and, for example, optimise descaling (ReduHeatLoss), estimate the microstructure, stress state and distortion properties (OptPro-Komp) and adapt straightening processes (PROTEUS), or predict tertiary scale formation on the cooling bed and estimate the surface quality from this (CAPRI).

Automation of process chains

Solutions for the comprehensive automation of process chains are realised on the basis of suitable information flows between systems in a longer process chain. Examples include process control in a steelworks from the tapping of a melt at the electric arc furnace or converter to its casting in the continuous casting plant (TotOptLiS), the prediction of the hydrogen content curve in liquid steel production (HydroPick) or the cross-process-stage equalisation of tensile strength and yield strength over the strip length (StrengthControl). The analytical process models used can be adapted to changing process conditions on a self-learning basis using modern algorithms (PerMonLiSt).

Optimisation of decarbonised process chains

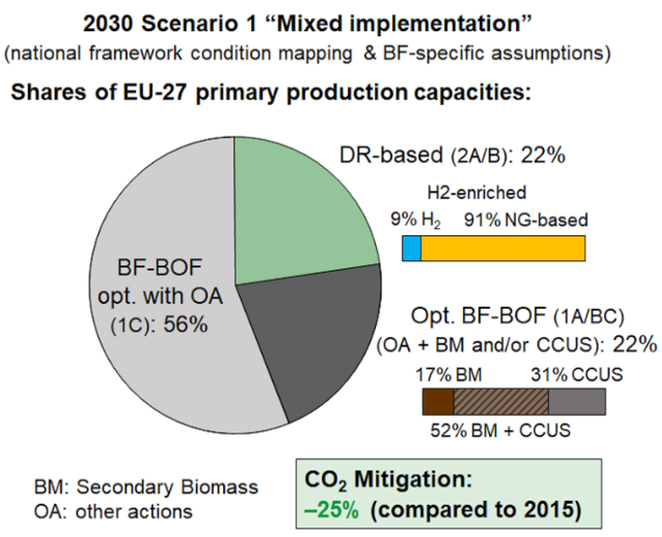

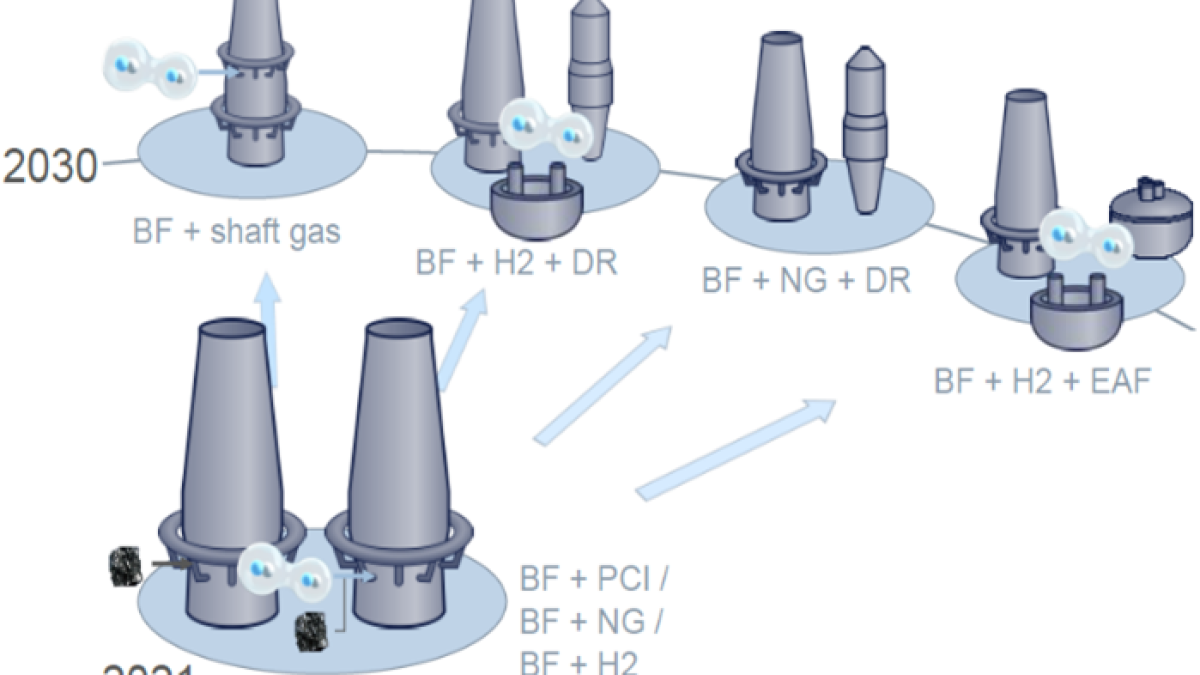

The decarbonisation of the steel industry is an extensive, complex and lengthy process that was analysed as part of the RFCS projects ‘Low Carbon Future’ and ‘GreenSteel for Europe’. Transformation roadmaps with plausible scenarios and recommendations for the necessary boundary conditions were created. The central processes and focal points include the conversion of integrated steelworks to direct reduction with hydrogen and electric arc furnaces (EAF/ESF).

The switch to renewable electricity and hydrogen with fluctuating prices and availability over time requires more flexible methods for planning and production management. The BFI supports this with various digital twins and an agent-based optimisation tool that optimises the gradual implementation of new subprocesses depending on the technical, financial and political boundary conditions and enables the flexible adjustment of production planning to availability and prices

Surface technology

Topics of surface technology are the development of surface protection concepts, the optimization of coating processes, the prediction of coating processes by simulation as well as the development of new coating systems and their testing. Various analysis and testing methods are available for the measurement (e.g. topography, contact angle), testing (nanoindentation, metallography, etc.) and evaluation (corrosion and tribology) of coating systems.

Electro plating

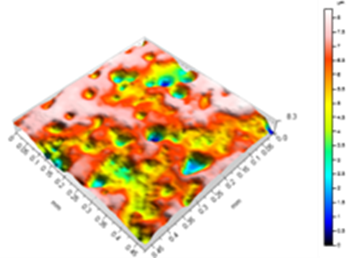

In the field of galvanic zinc and zinc alloy plating, the electrolyte itself (TailoredZA, EfficientELO), current modulation (e.g. pulse plating) (TailoredZA), the electrodes or the cell (EfficientELO, ELOTOP), the precision of strip roughness prediction (ELOTOP) and the use of zinc-containing residual materials for electrolytic strip galvanizing were investigated in various projects.

Oxide scale conditioning and protective coatings

Scale protection coatings are a special field. They have been developed and tested in recent years (laboratory furnaces) and adapted for various applications. The basis is formed by coatings that serve as an oxygen barrier and thus minimize scale and material losses (TempKorroSchu, HiPerScale). Other coating systems and adaptations additionally reduce tool wear (NanoZunKonLub), improve descaling (HiPerScale) and reduce secondary scale formation and strip roughness (INFIRE). The systems are currently being tested for their effectiveness under modified reheating conditions - e.g. the use of H2 in reheating furnaces (H2HotRoll, HYDREAMS, E-ECO Downstream). Various online-capable calculation models for reheating, scale formation, cooling and descaling are available for the prediction of scale-related surface defects (INFIRE, ReduHeatLoss, CAPRI). These models are validated by accompanying industrial tests and implementation of e.g. optical process measurement technology such as residual scale detection (HiPerScale, INFIRE, ReduHeatLoss).

Wear protective coatings

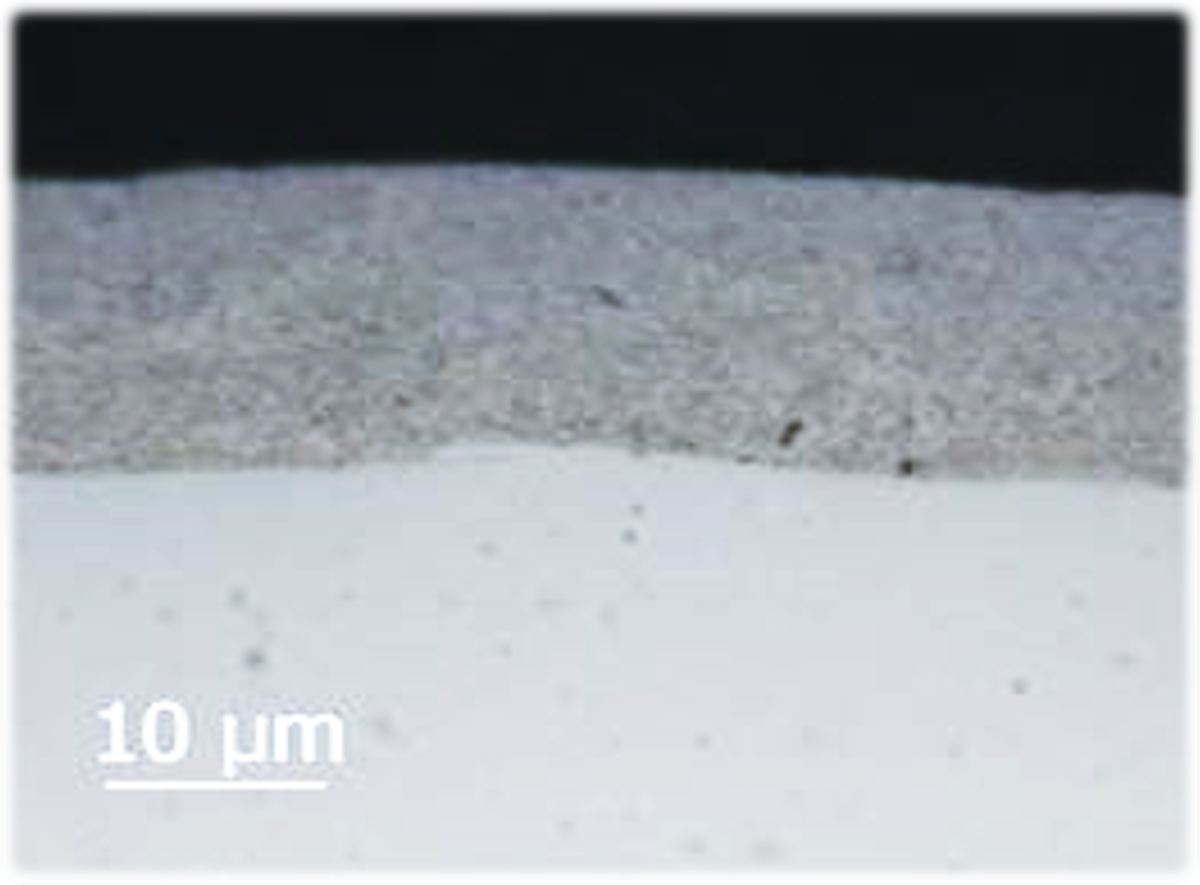

The BFI has extensive expertise in this area, e.g. in the application and optimization of electroless nickel dispersion coatings with embedded hard material particles (ReduWearGuid) as a Cr(VI) substitute (TriboSim, HEROLL) or as a basis for non-stick coatings with embedded functional fibres (Non Stick-FiReNi)

Tribology and lubrication technology

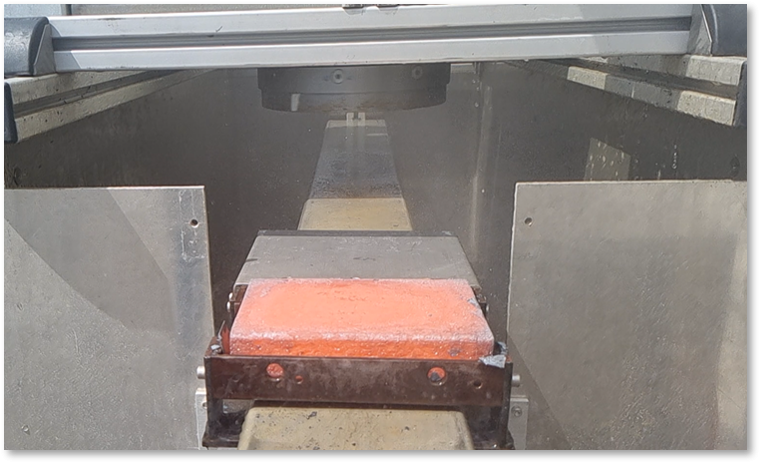

Tribology deals with the optimization of friction and wear on plant components and working tools with the aim of improving the product surfaces quality or increasing the productivity of processes.

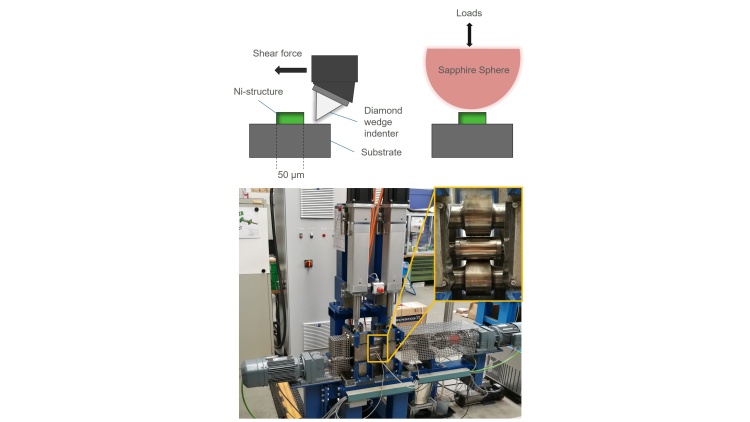

With a wide range of tribological test equipment (wear test rigs), the BFI has supported many projects dealing with the wear of tools, such as cold and hot work rolls (ReduHeatLoss, HEROLL, RollOilFree, RollOilFree 2, TriboSim), closed dies (NanoZunKonLub, Nanocarbides 2), cutting tools (IntellCutProcess, Non Stick-FiReNi, Nanocarbide 2) and tool steels (Nanocarbides, Nanocarbides 2) as well as system components such as bearings (TriboCoat, OptProKomp), rollers (ReduWearGuide, ReflexRolle, NoStickRolls, ReduHeatLoss) and guide systems (ReduWearGuid).

Wear protective coatings

Wear protection coatings such as thin-film systems (IntellCutProcess), thermal spray coatings (ReduWearGuid, ReflexRolle, NoStickRolls and deposition welding (ReduWearGuid) have been developed as part of various projects and have been tested under very complex load conditions at the BFI and in industrial environments.

Lubrication technology

In the field of lubrication technology, the BFI is involved in the development of general solutions for hot and cold rolling (HEROLL), is a pioneer in the preparation of rolling processes for oil-free lubrication (RollOilFree, RollOilFree 2) and has built up expertise in the dry lubrication of hybrid bearings (TriboCoat).

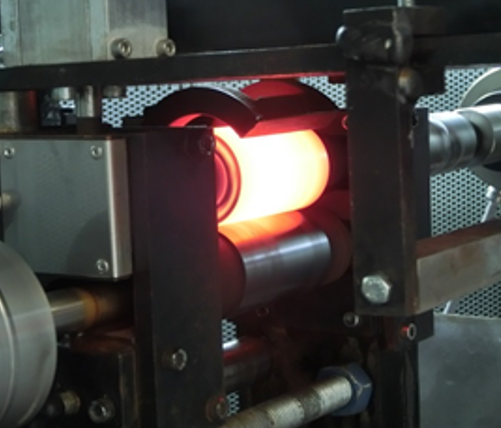

Effects of decarbonization on the product and process quality of downstream processes

During reheating for the hot forming of steel, a reaction with the components of the gas atmosphere always takes place on the surface in the presence of oxygen carriers. The use of hydrogen as a fuel gas is expected to have more serious effects on product quality than natural gas combustion. The consequences can be increased material loss due to oxidation (scale formation), material changes near the surface due to diffusion processes (decarburization, internal oxidation, embrittlement due to hydrogen absorption) and descaling problems due to more adhering oxides (scale scars, red scale, etc.). To evaluate these material reactions, the BFI has several laboratory furnaces with different test parameters at its disposal (laboratory furnaces).

Product quality

The effects of hydrogen enrichment of the fuel gas on the oxide scale formation on steels (H2HotRoll, HYDREAMS, E-ECO Downstream), its descaleability (H2HotRoll, E-ECO Downstream), its tendency to decarburize (HYDREAMS), hydrogen absorption and embrittlement (HYDREAMS, Nanocarbides 2, E-ECO Downstream) are currently being investigated and evaluated.

Plant components

Another important field of work is research on the effects of hydrogen-enriched fuel gas and its combustion gas on furnace components, such as 3D-printed burner components and refractory materials (HYDREAMS, E-ECO Downstream)

Projects on this topic

PerMonLiSt - Continuous performance monitoring and calibration of model and control functions for liquid steelmaking processes

HydroPic - Analysis and control of hydrogen content during steelmaking

TriboSim - Experimental and simulative evaluation of wear on roll coatings

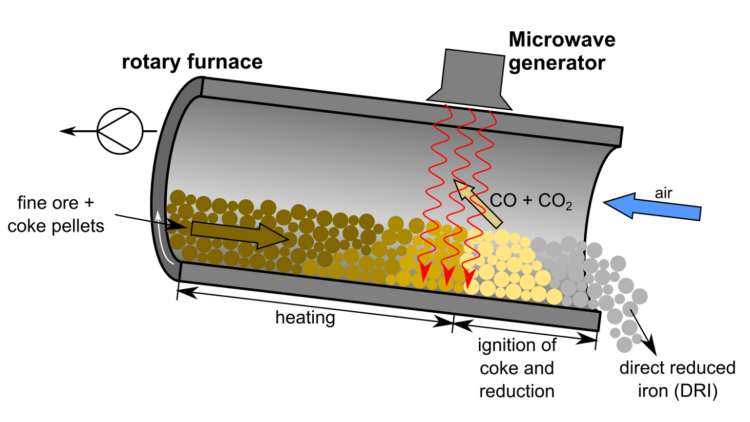

DESTINY - Development of an Efficient microwave System for material Transformation in energy INtensive processes for an improved Yield

Your contact persons

6 Martin Wunde, M.Sc.

+49 211 98492-316

martin.wunde_at_bfi.de

7 Dr. Thorsten Hauck

+49 211 98492-301

thorsten.hauck_at_bfi.de