Project overview

Process optimisation

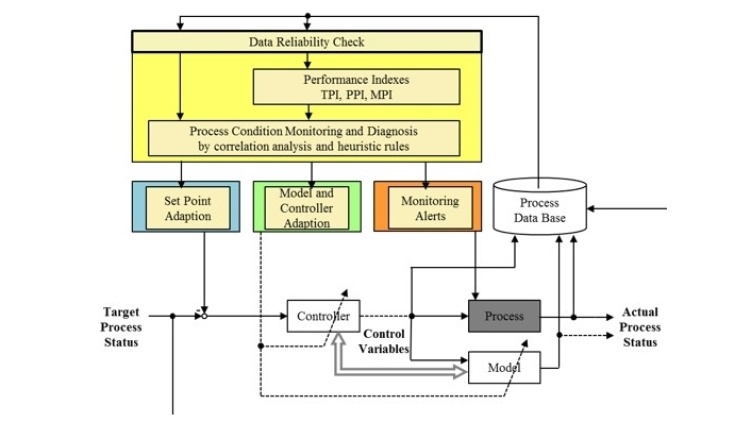

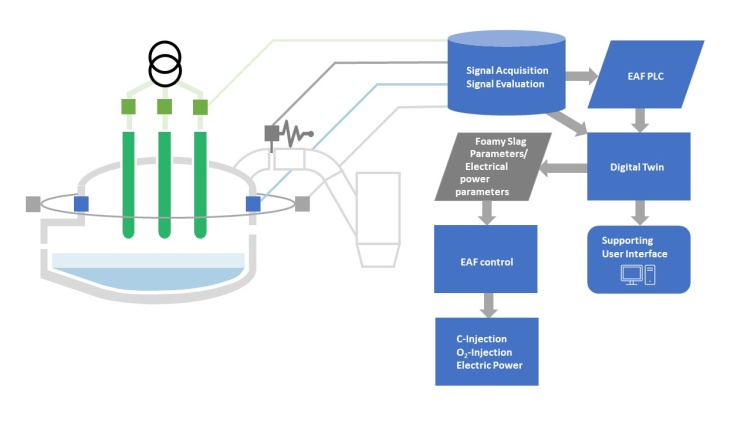

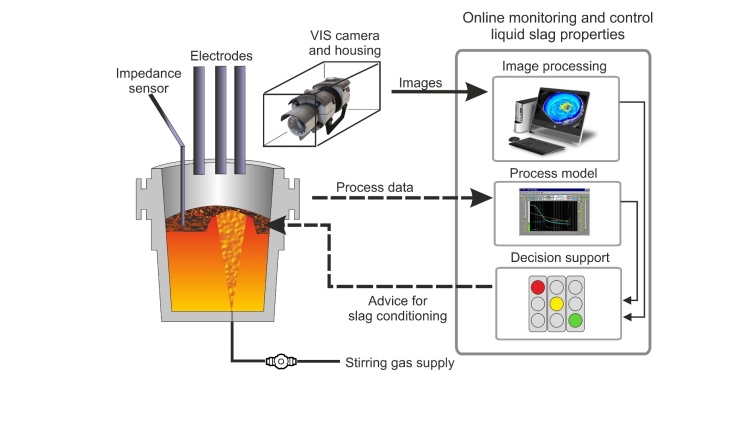

PerMonLiSt - Continuous performance monitoring and calibration of model and control functions for liquid steelmaking processes

HydroPic - Analysis and control of hydrogen content during steelmaking

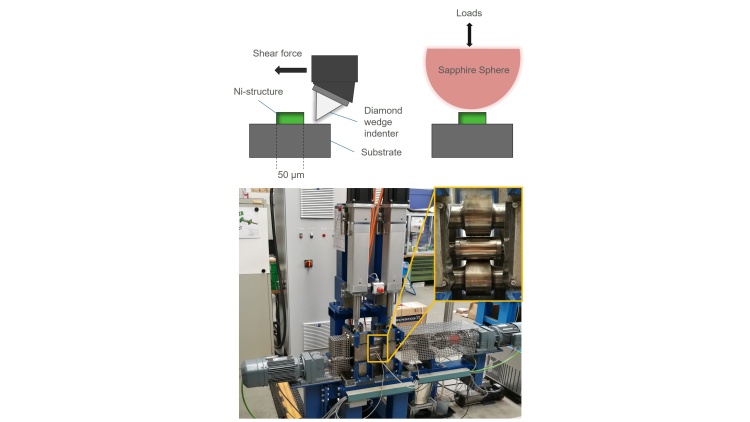

TriboSim - Experimental and simulative evaluation of wear on roll coatings

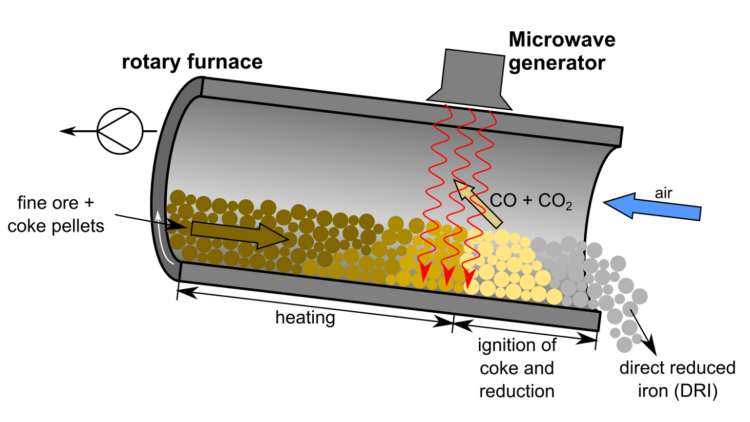

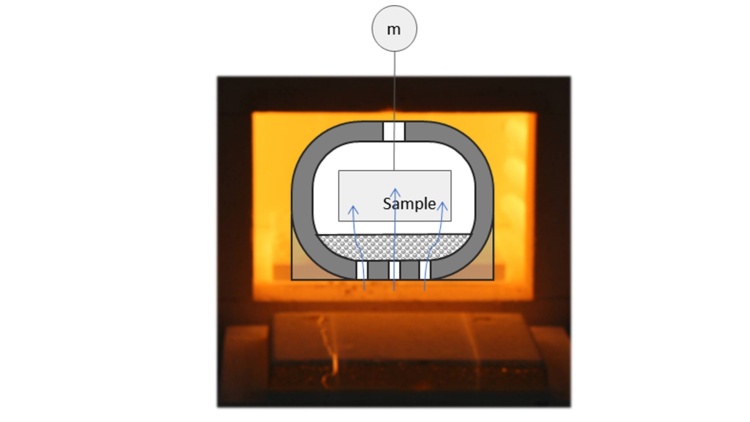

DESTINY - Development of an Efficient microwave System for material Transformation in energy INtensive processes for an improved Yield

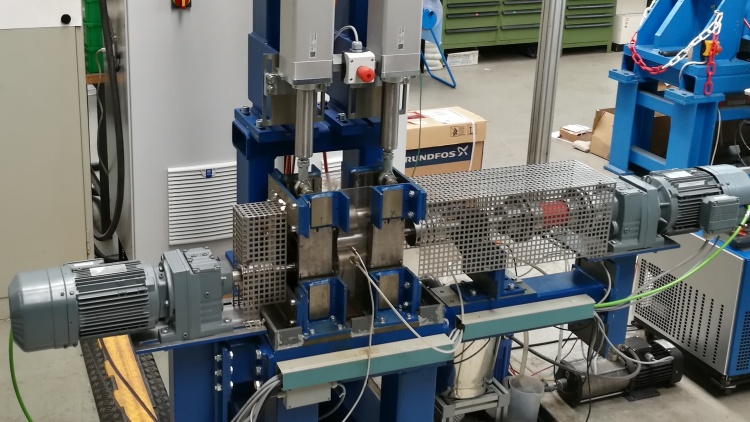

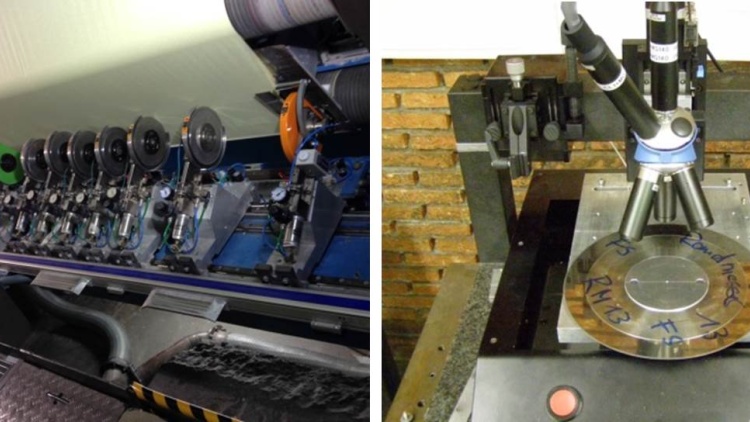

Rolloilfree II - Transfer of aqueous oil free lubricants into steel cold rolling practice

TailoredZA - Tailored structure of multi-layer zinc alloy coatings to improve forming and corrosion protection properties

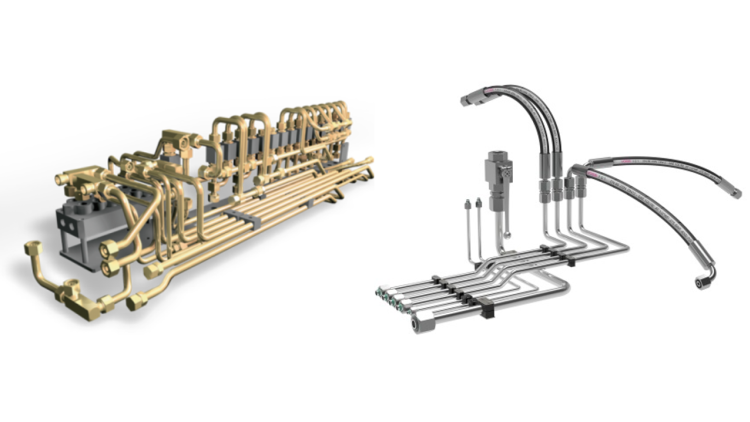

METACAST - Mapping, Educating, Training, Applying models in continuous CASTing

SunShine – Sustainable new casting and rolling process monitoring / sensoring approach aimed at proper surface quality and shape in flat and long products

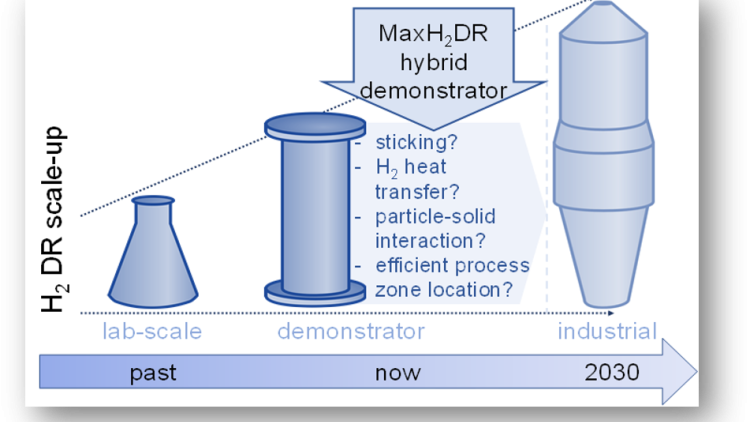

MaxH2DR - Enrichment of Hydrogen in the direct reduction process

REVaMP – Retrofitting of sensors and optimization tools for the efficient use of variable input materials in the metal-producing industry

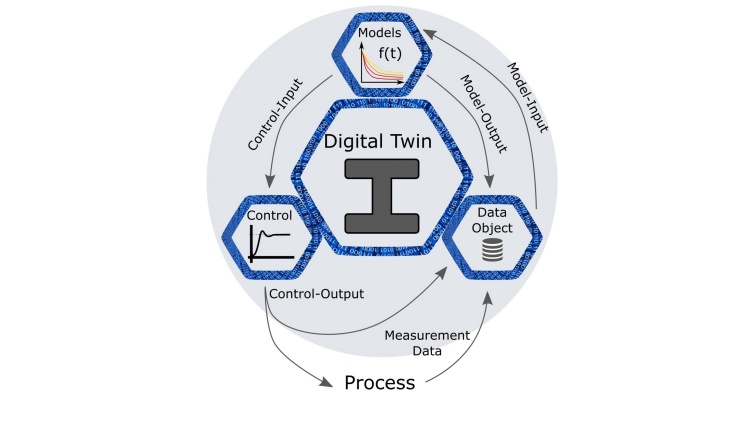

DiGreeS - Demonstration of Digital twins for a Green Steel value chain

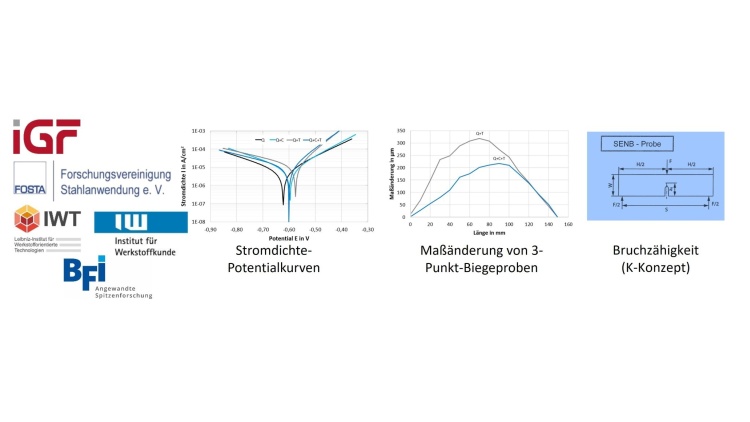

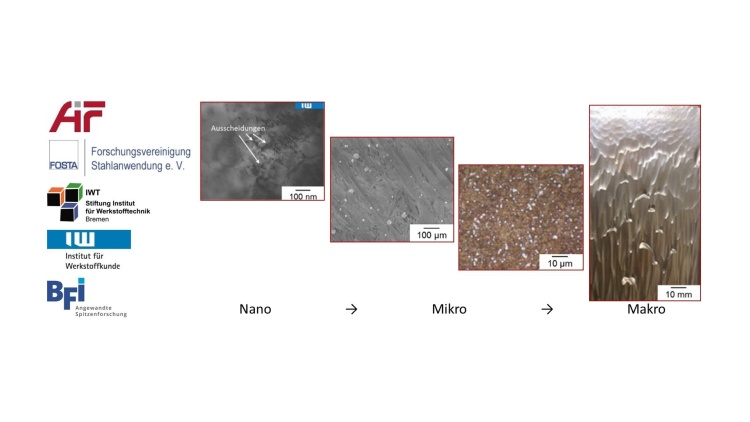

Nanocarbides II – Influence of deep cryogenic treatment on distortion, corrosion and fracture toughness

MinSiDeg - Minimisation of sinter degradation between sinter plant and blast furnace exploiting embedded real-time analytics

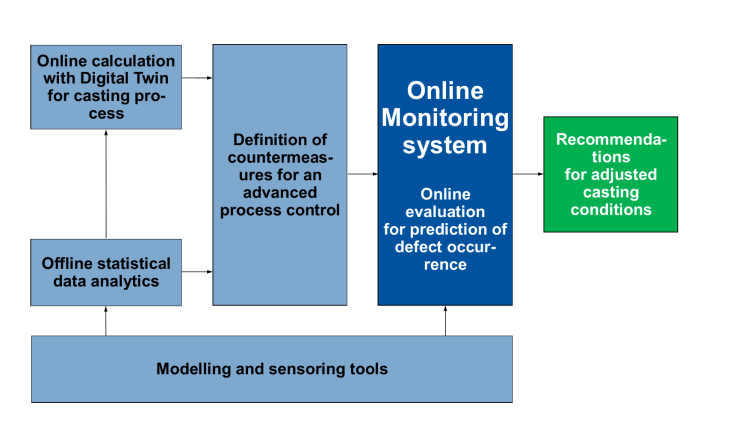

RealTimeCastSupport- Embedded real-time analysis of continuous casting for machine-supported quality optimisation

Rolloilfree – Steel cold rolling with aqueous oilfree lubricants

Reduwearguid – Reduction of wear on guiding components in hot rolling finishing and coiling line for improved service life time and product surface quality

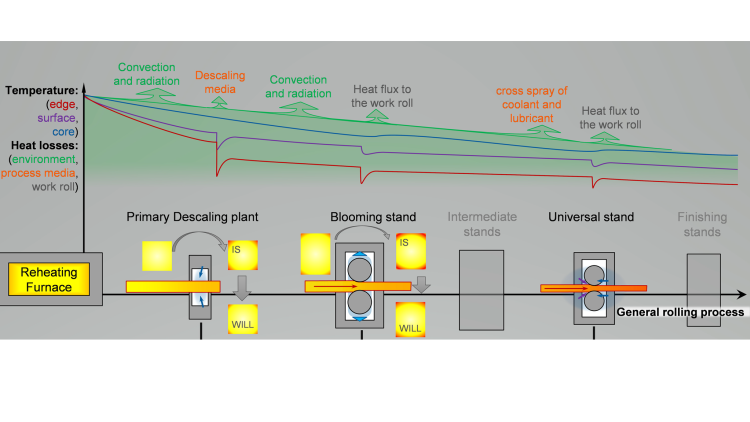

ReduHeatLoss – Reduction of Heat Losses during Hot Rolling of Long Products

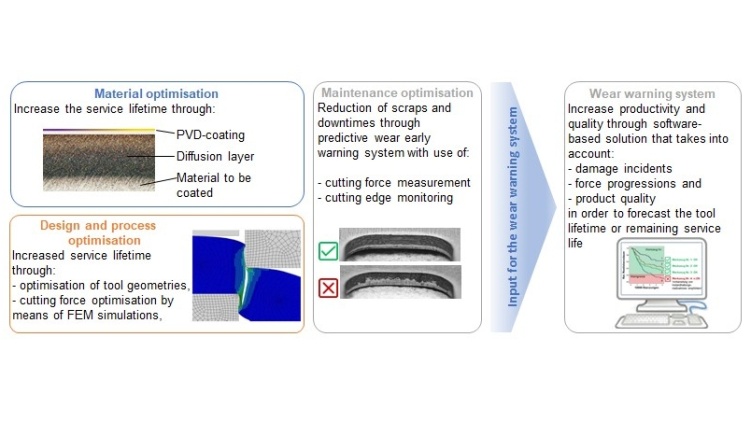

IntellCutProcess – Optimisation of cutting processes using intelligent cutting tools

iSLAG – Optimising slag recycling through on-line characterization devices and intelligent decision support systems

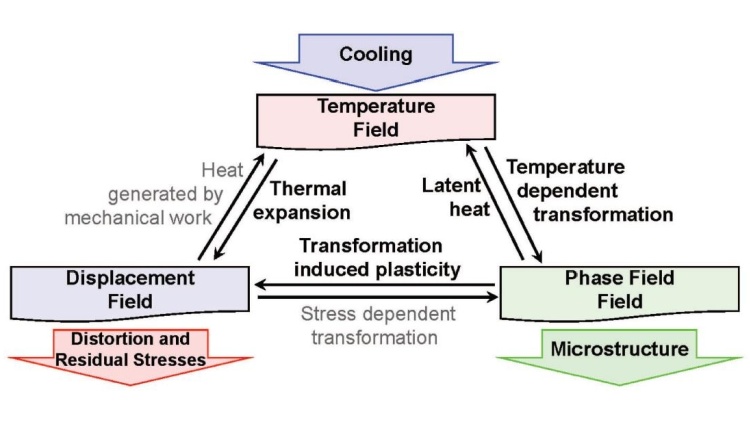

PROTEUS-RS – Long Product Quality Optimisation through Enhancement and Utilisation of Residual Stress minimising Process Strategies

OptProKomp

non stick-FiReNi – Development of stress compatible coating systems for the optimization of cutting tools

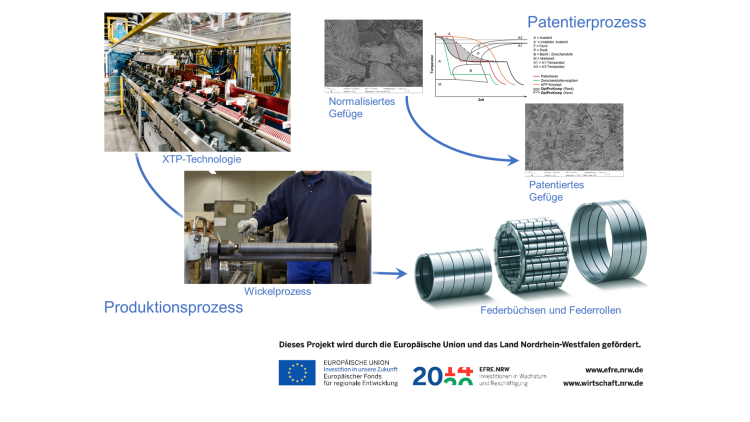

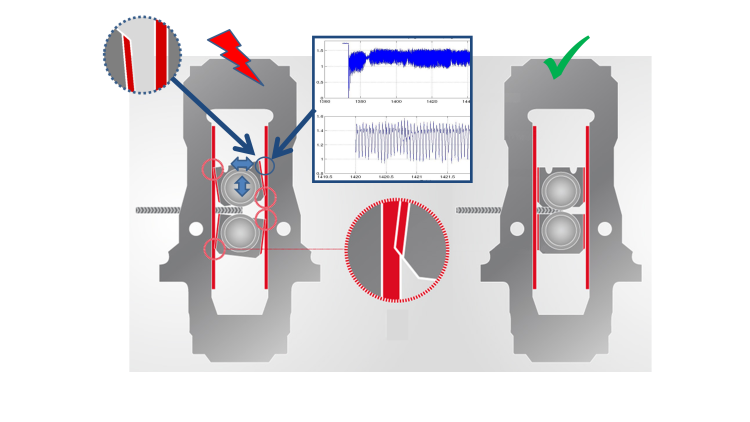

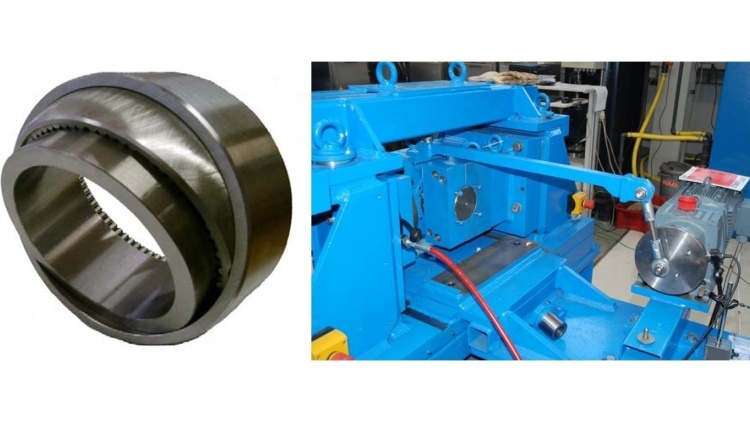

FlexGap – Industrial demonstration of novel adaptive flat bearing

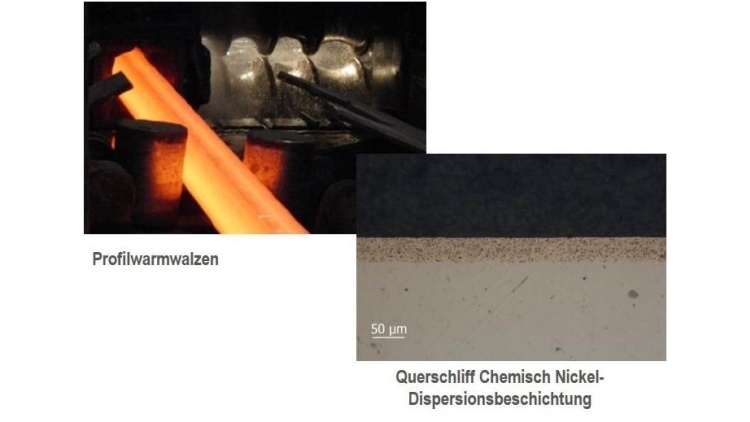

Electroless nickel dispersion coating for wear protection

Infire – Strategy to increase the hot strip rolling performance in terms of surface quality, final properties and reproducibility

TempKorroSchu

Optimal Residual Stress Control – ORSC

CoolCut – Development of an innovative industrial cutting technique for highly abrasive web-type material

Nanocarbides – Enhancing technological properties of tool steels by cryogenic treatment

TriboCoat – Optimization of highly stressed sliding contacts by the use of innovative coating and surface concepts

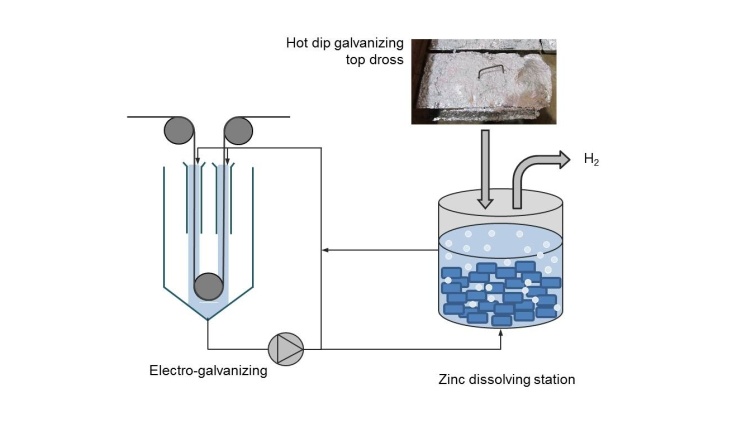

EfficientELO – Energy and resource efficient electro-galvanizing of steel strip

Mikrokaltschmieden – Application of machine hammer peening on profiled rolls for wear reduction and improvement of the surface quality and dimensional stability of hot-rolled profiles

InnoZun – Development of a process combination to improve the surface quality of pickled stainless steel strip using additives for secondary scale conditioning in combination with new innovative descaling and pickling processes

BOFdePhos – Control of Dephosphorisation in BOF process

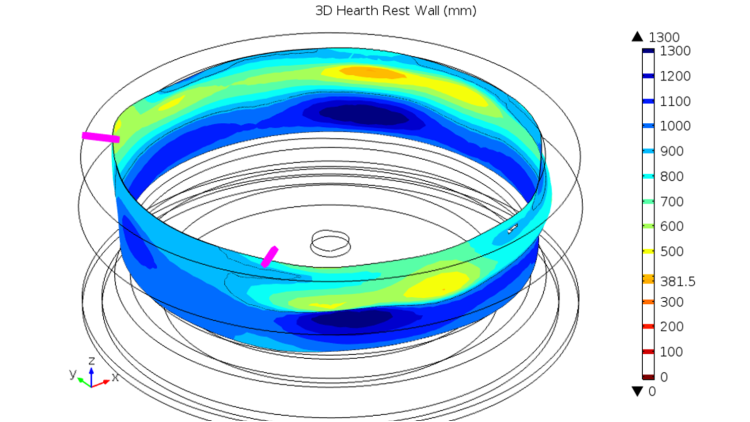

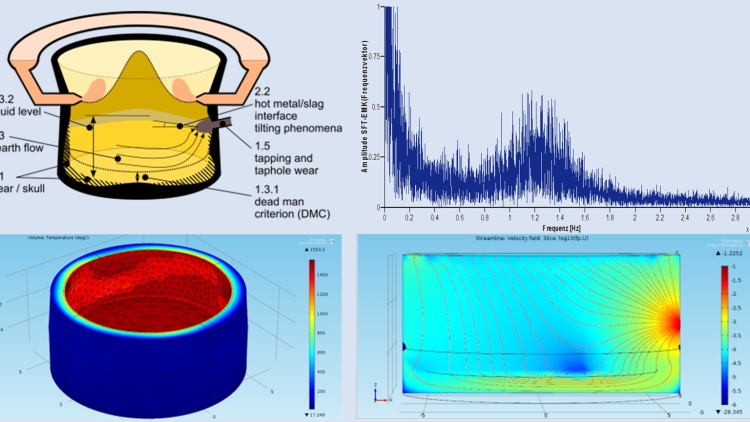

OptiBlaFIns – Analysis of blast furnace hearth state

NanoZunKonLub – Application of nanoparticle enhanced coatings for scale conditioning in die forging processes in order to optimize the tribological system

HiperScale – High performance hot rolling process through steel grade-dependent influencing of the scale formation and flexible descaling control

DissTec - Valorisation and dissemination of technologies for measurement, modelling and control in secondary metallurgy

SUSTAINTAP – Blast furnace sustained tapping practice

S5 – Integrated thickness and flatness control