Project overview

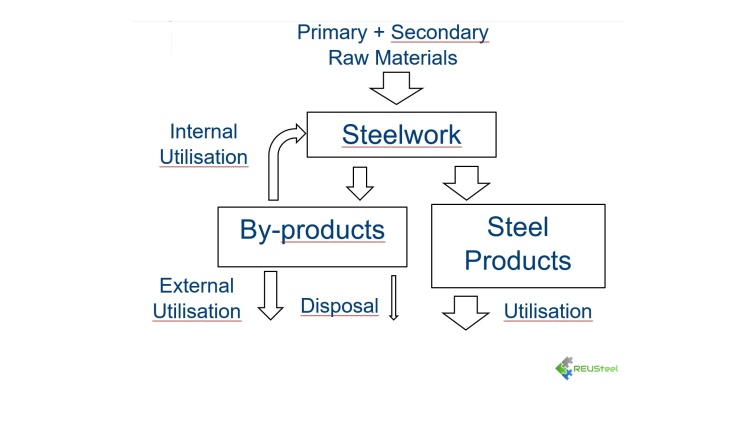

Circular economy

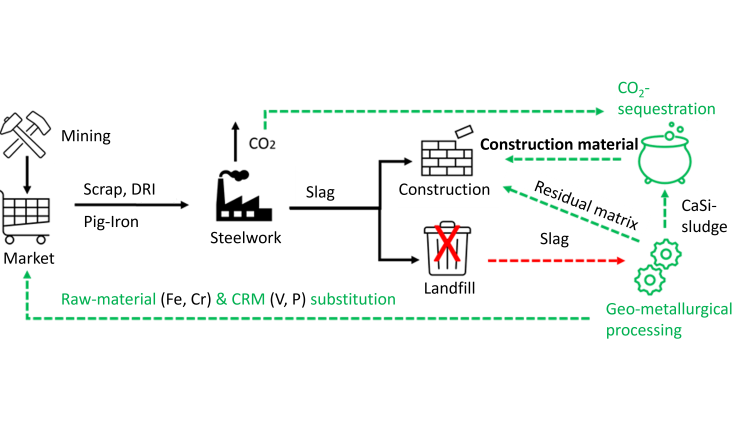

GeoCRM - Geometallurgical processing of steelmaking slag for recycling critical raw materials and CO2 binding

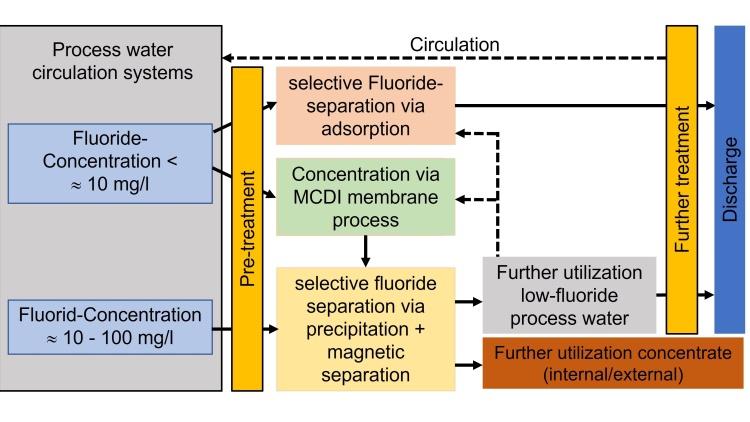

FluoridSelektiv - Process development for selective fluoride separation from industrial process water

ZinkAtline - Development of an atline measuring method for rapid analysis of the total zinc content in process water

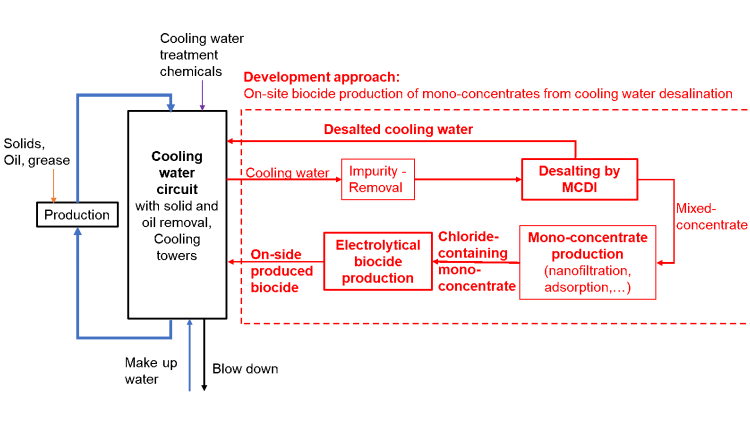

Konzentrat-Biozid - Development of a reliable process for cooling water desalination based on membrane-assisted capacitive deionization with production of monoconcentrates

WEISS_4PN - Integrative application of innovations and digital cooling capacity management to reduce water consumption in steel production – Sub-project 2: Forecast of operational scenarios of cooling circuits due to climate-related bottlenecks and determination of disturbing influences when using the Capacitive Deionization (MCDI)

ZHyRON - Valorisation of iron-rich & Zinc-containing steelmaking by-products via HYdrogen-based ReductiON

IndiWater - Independent industrial water supply by digitalization, simulation and innovative treatment technologies

TransZeroWaste - Upgrading of low-quality iron ores and mill scale with low carbon technologies

DuMiCo - Dust minimisation and control at the blast furnace

CORNERSTONE - Combined technologies for water, energy and solute recovery from industrial process streams

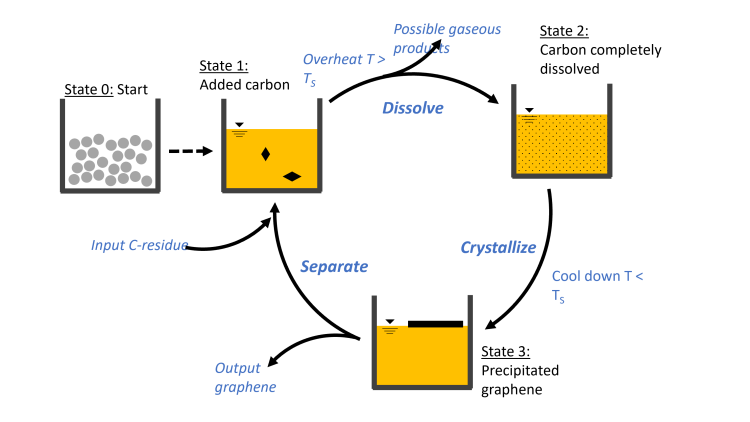

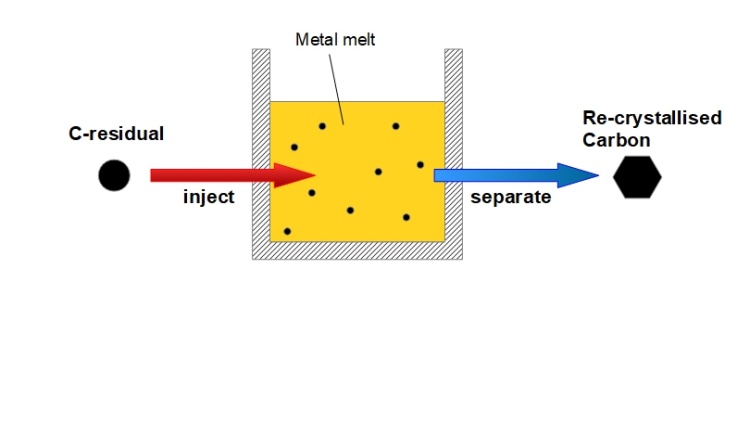

RekCarb 2 – Recrystallisation of Carbon containing Residuals to Graphene-Nano-Platelets

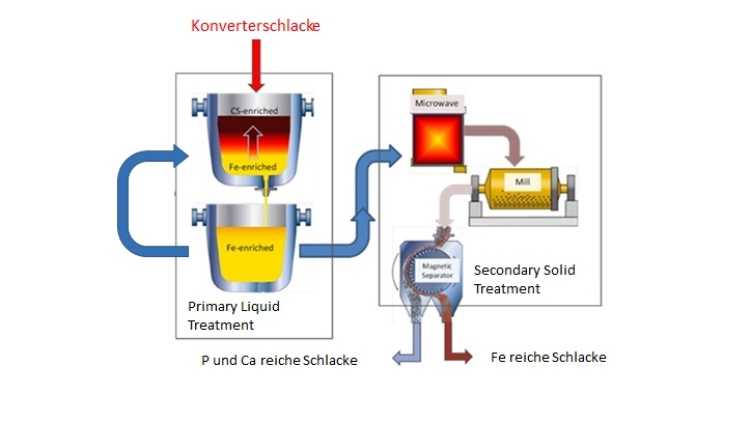

InSGeP - Investigations of Slags from Next Generation Steel Making Processes

MiningWater – Mining water recovery using innovative technologies for saving fresh water

RekCarb – Upcycle of carbon containing residuals and by-products through recrystallisation in molten metals

Slagreus – Reuse of slags from integrated steelmaking

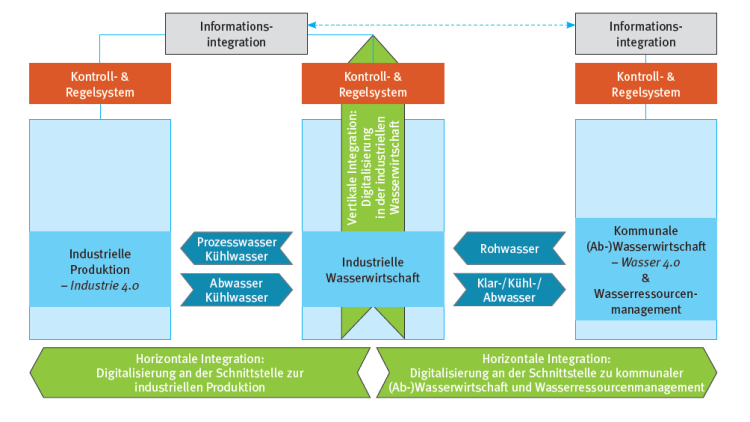

DynaWater4.0 – Dynamic value creation networks through digital collaboration between industrial water management and production

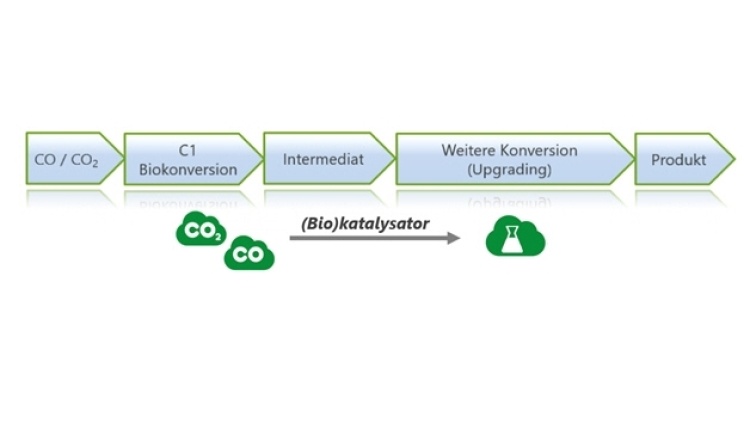

BioCOnversion – Bioconversion of CO/syngas into a plastic precursor

SPOTVIEW – Sustainable Processes and Optimized Technologies for Industrially Efficient Water Usage in steel, dairy or pulp and paper industry

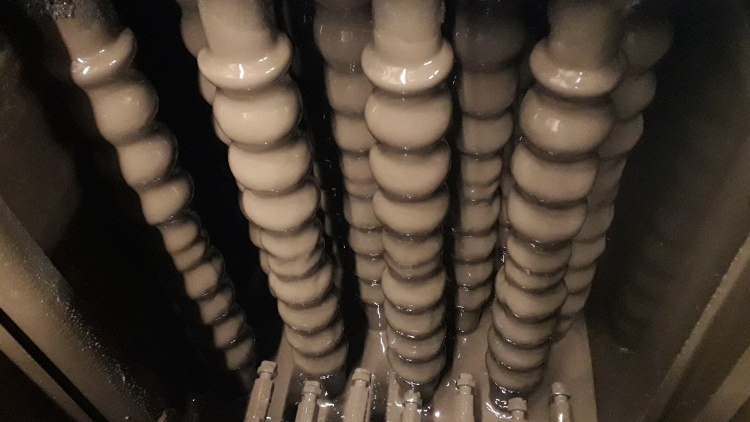

HiJetRod Pilot – Resource-efficient hydromechanical descaling system for wire coils

INSPIREWATER – Innovative Solutions in the Process Industry for next generation Resource Efficient Water management

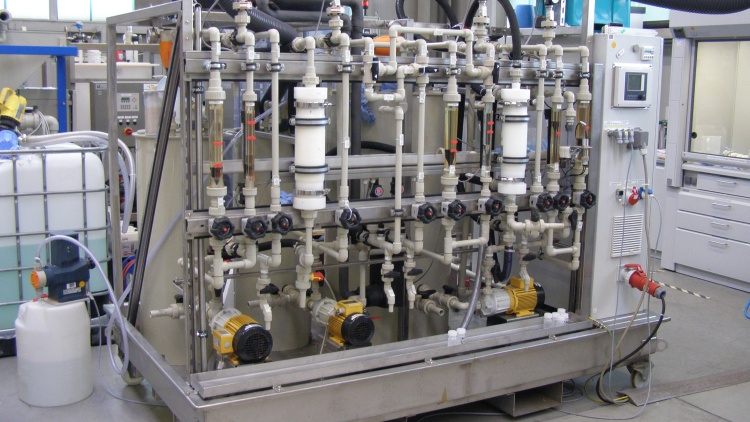

WEISS – Efficient operation of cooling water circuits by integrated desalination at the example of the steel industry

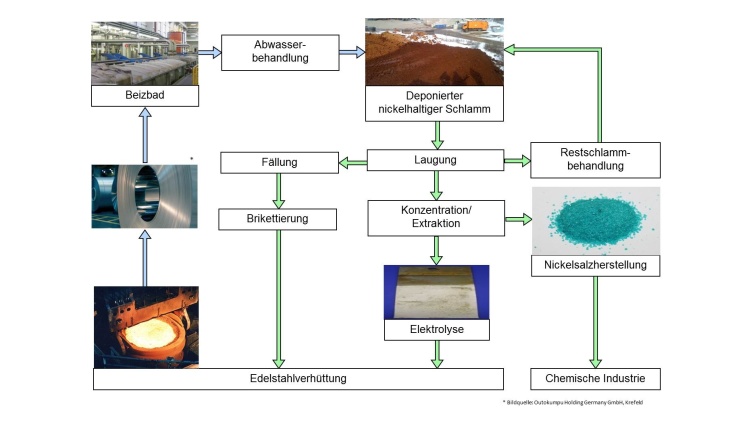

UrbanNickel – Recovery and recycling of nickel from deposited neutralization sludge of the stainless steel industry

Schwermetall-Adsorber – Development of an adsorption material for selective heavy metal removal from industrial process waters

Schmelzinjekt2 – Recycling of zinc-containing filter dust

NickelRück – Recovery of nickel from process waters of phosphating

PSP-BOF – Removal of Phosphorus from BOF-slag