Project overview

Digitisation and process measurement technology

AgiFlex - Agent-based models minimizing carbon usage in flexible and efficient future integrated steelworks

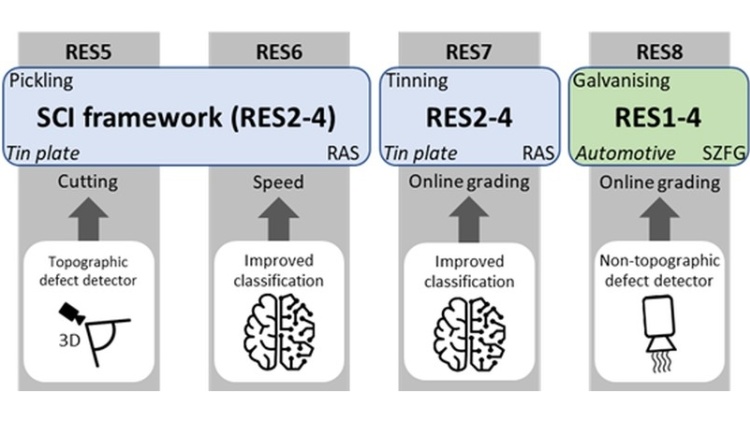

SufConInspect - Enabling zero-defect manufacturing for flat steel production by means of optimized inspection results and a new level of online surface quality control

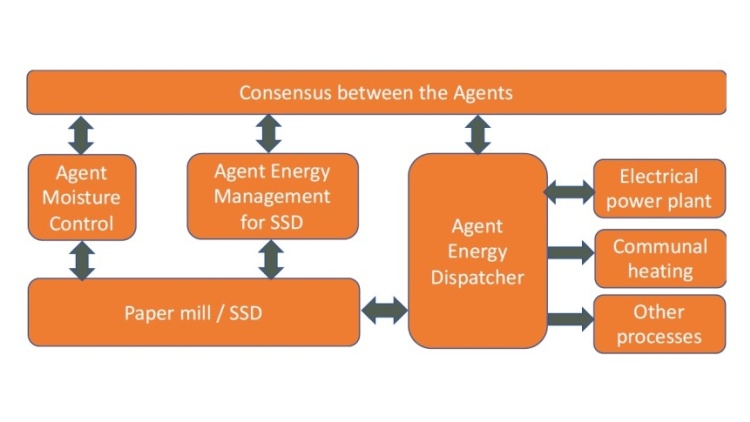

SteamDry - Superheated steam drying for sustainable and recyclable web-like materials

RoboInspect - Mobile Robots for Inspection of Steel Plants

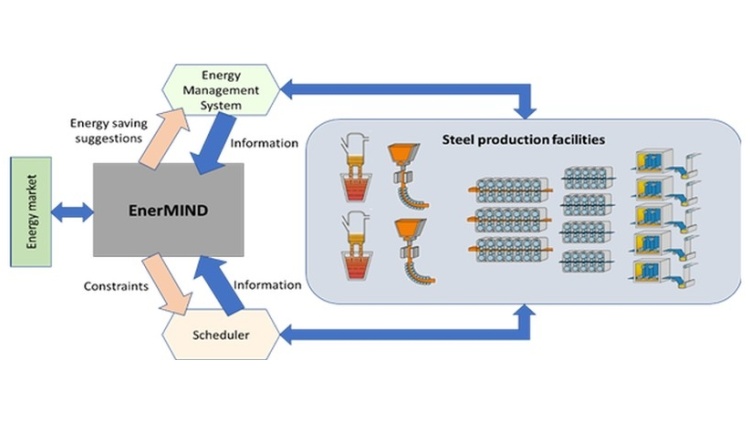

EnerMIND - Energy Management in the Era of Industry 4.0

OptDeslag - Increased yield and enhanced steel quality by improved deslagging and slag conditioning

DynStir - Dynamic stirring for improvement of energy efficiency in secondary steelmaking

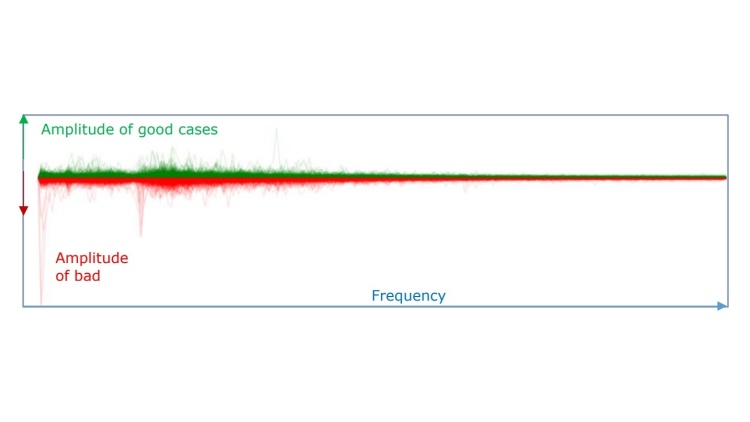

PRESED - Predictive Sensor Data mining

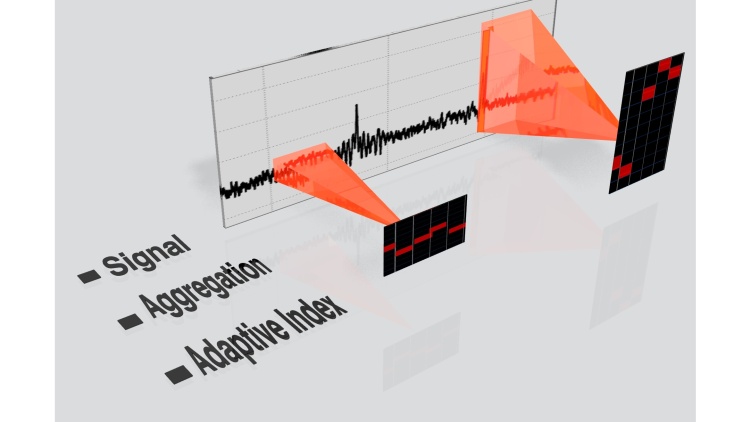

SitErk - Continuous optimisation of processes and systems in industrial production through the automatic recognition of process situations based on high-resolution system and process data

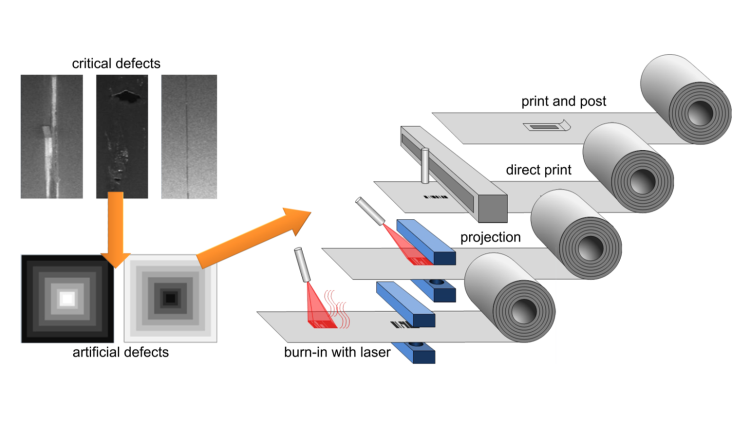

CheckSIS - Performance assessment for automatic surface inspection systems

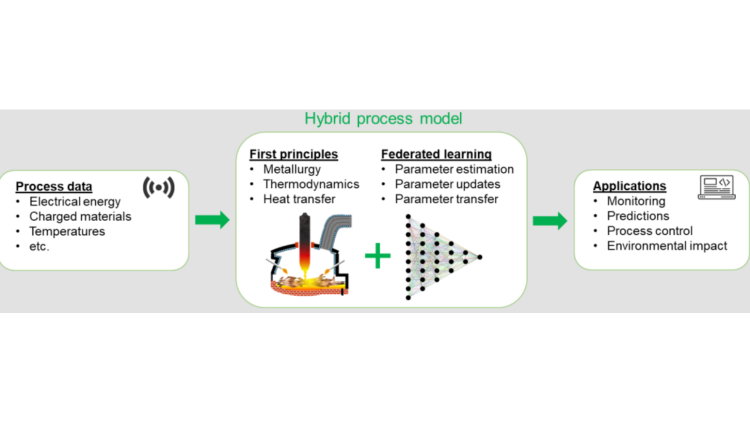

ALCHIMIA - Data and decentralized Artificial intelligence for a competitive and green European metallurgy industry

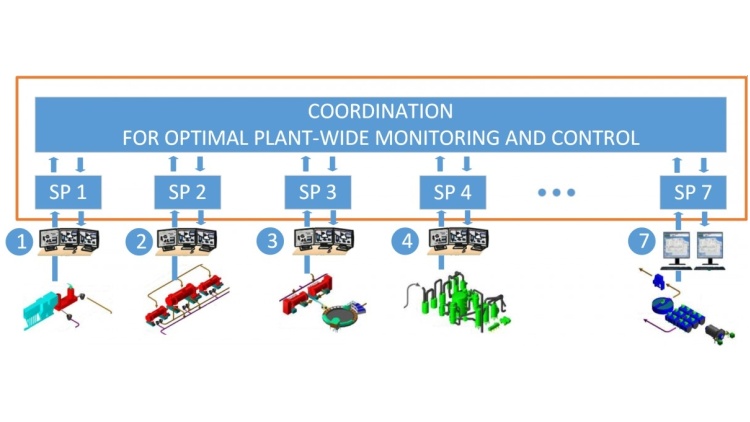

COCOP- Coordinating Optimisation of Complex Industrial Processes

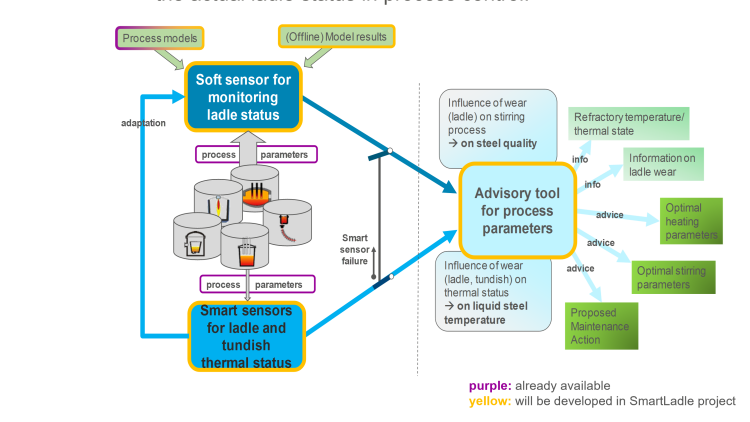

SmartLadle - Smart consideration of actual ladle status monitored by novel sensors for secondary metallurgy process parameters and ladle maintenance strategies

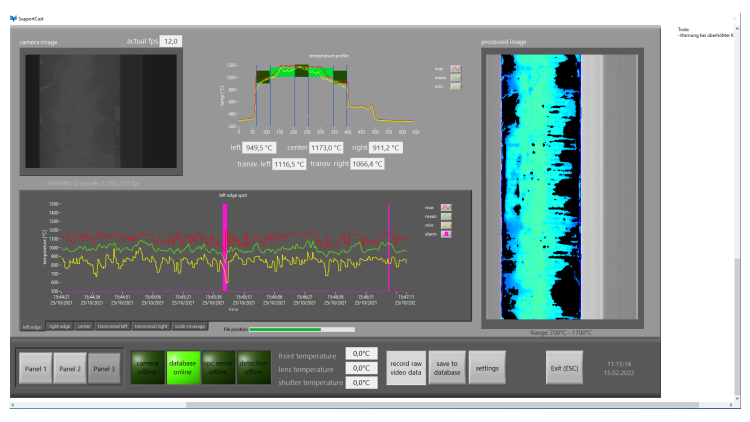

SupportCast - Supporting Control by Inspection of Surface Quality and Segregation on Cast Products through integration of Novel Online Monitoring and Advanced Modelling into an Accessible Cloud Access Platform

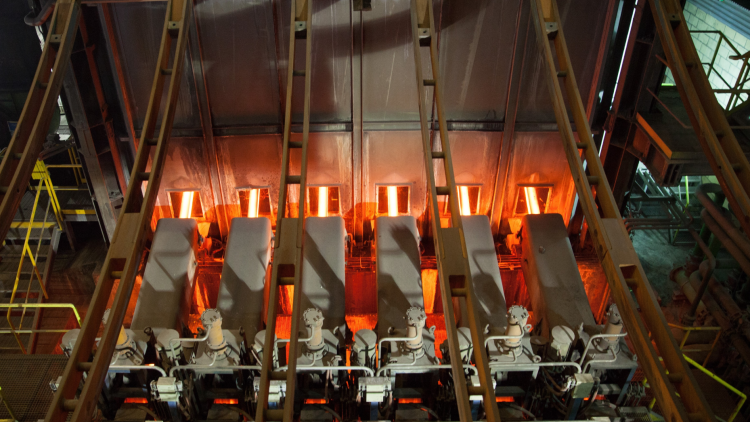

OpConDigiCast - Digital Twin Technology for Comprehensive Simulation, Optimization and Control of Continuous Steel Casting Process

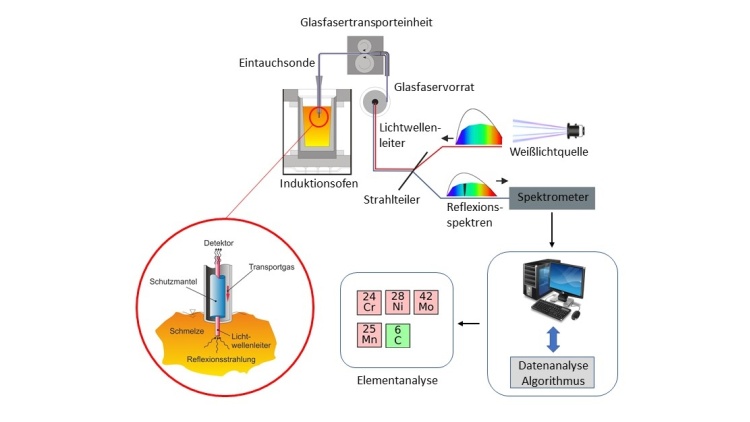

OMiAS - Optical online measurement method for in-situ analysis of the chemical composition of a steel melt during liquid steel production

CAPRI - Kognitive Automatisierungsplattform für die digitale Transformation der europäischen PRozess-Industrie

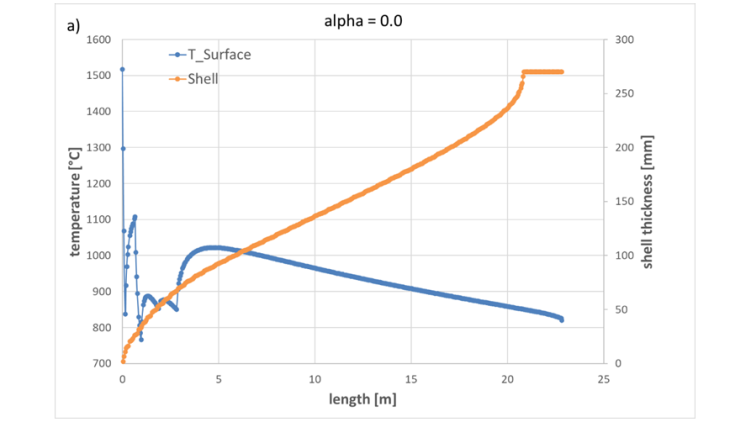

ConSolCast – Comprehensive modelling, monitoring and control of solidifcation for optimisation of continuous casting process

TrackOpt - TrackOpt - Consistent ladle tracking for optimization of steel plant logistics and product quality

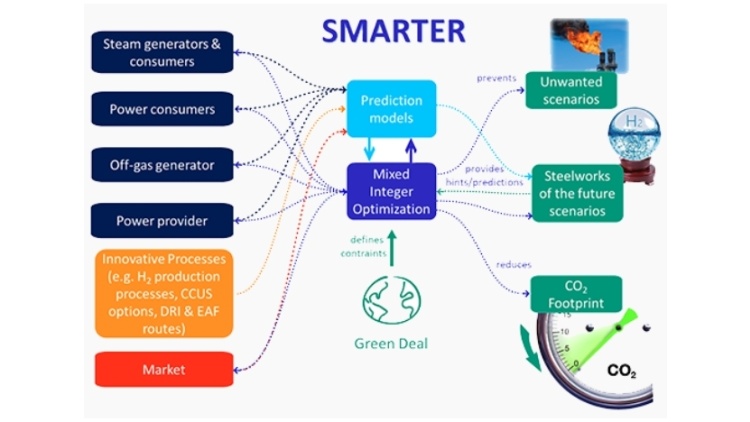

SMARTER - Steam and gas network revamping for the steelworks of the future

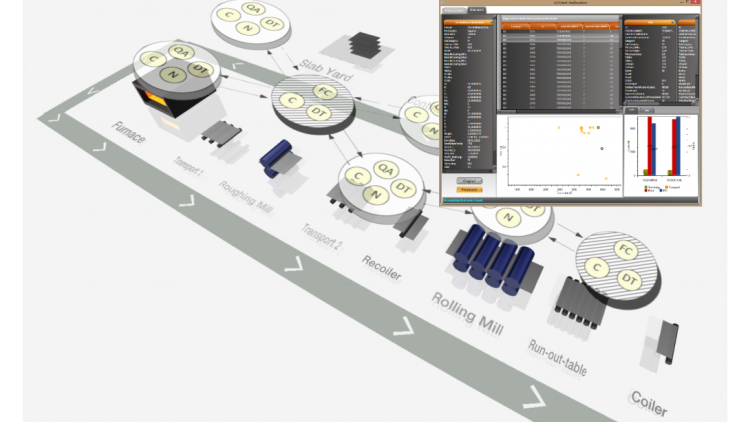

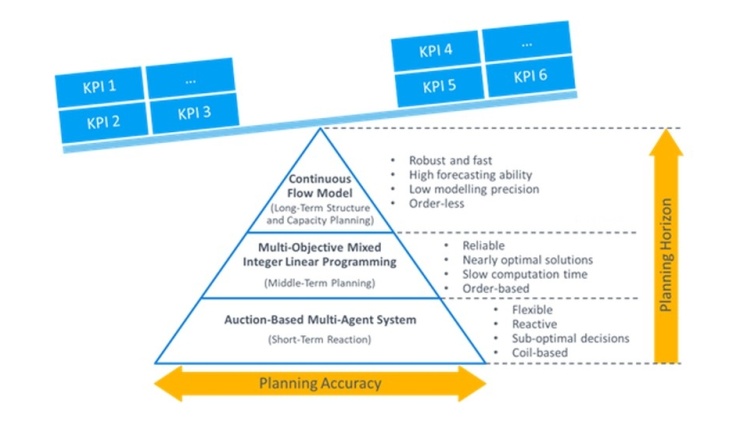

DynReAct_PDP - Roll-out refinement of production scheduling through dynamic product routing, considering real-time plant monitoring and optimal reaction strategies

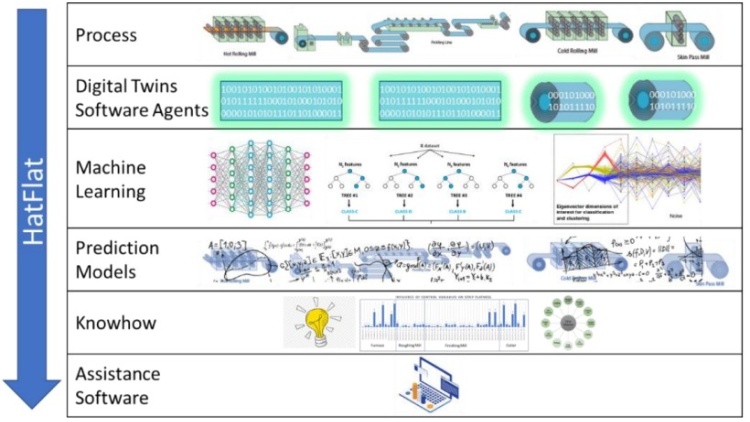

HatFlat - Holistic Assistance for Cross-Process Analysis and Prediction of Strip and Plate Flatness

s-X-AIPI – self-X Artificial Intelligence for European Process Industry digital transformation

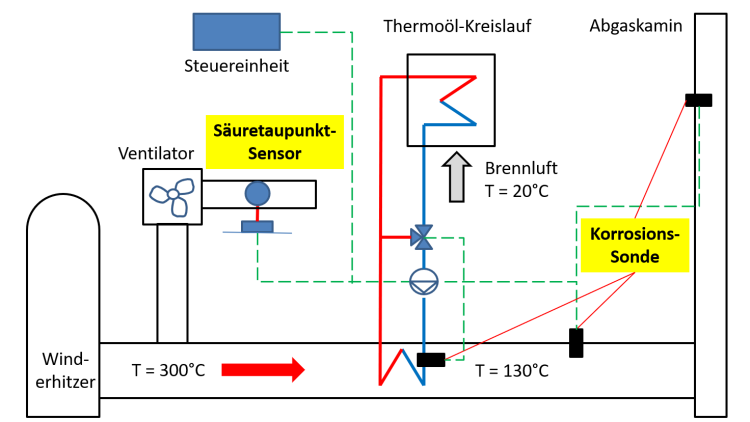

SafeDewPoint – Acid dew point and corrosion sensors for dynamic waste heat recovery from steel mill flue gases

DroMoSPlan – Drones for autonomous Monitoring of Steel Plants

Quality4.0 – Transparent product quality supervision in the age of Industry 4.0

MACO Pilot – Optimierung der Online-Konzentrations-Überwachung und Regelung an Edelstahl-Mischsäurebeizanlagen

TotOptLis – Through-process optimisation of liquid steelmaking

stackMonitor – Online Blast Furnace Stack Status Monitoring

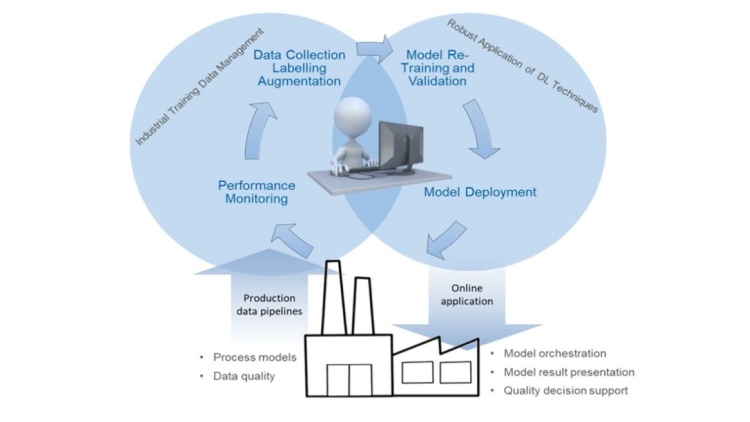

DeepQuality – Use of robust deep learning methods for the automatic quality assessment of steel products

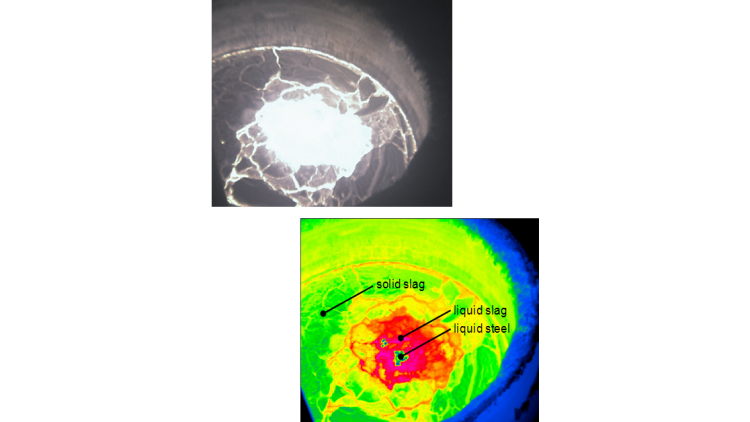

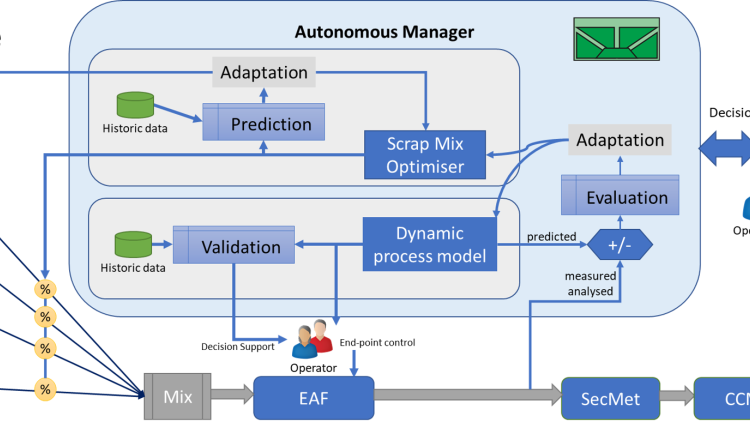

MeltCon – Determining process conditions for online monitoring of temperature and carbon content in the electric arc furnace to optimise end point control

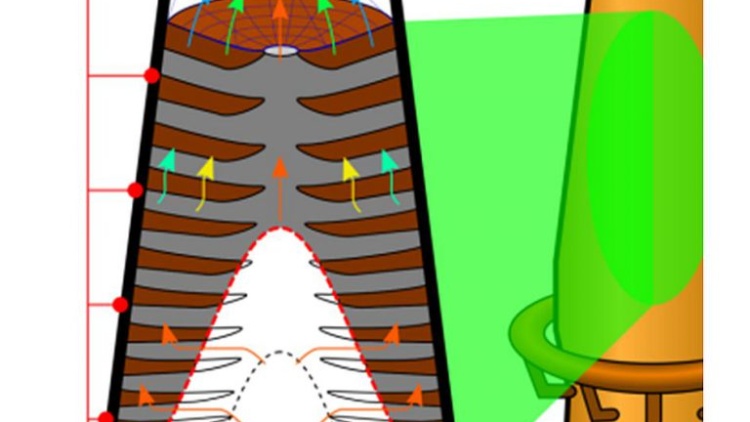

TopTemp – Shaft furnace analysis with acoustic gas temperature measurement

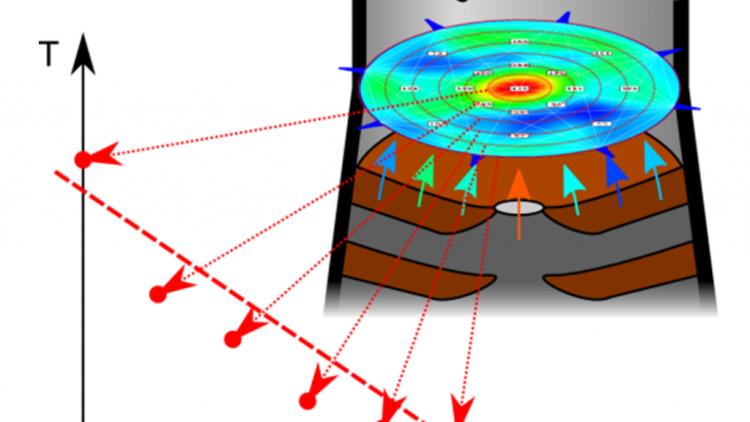

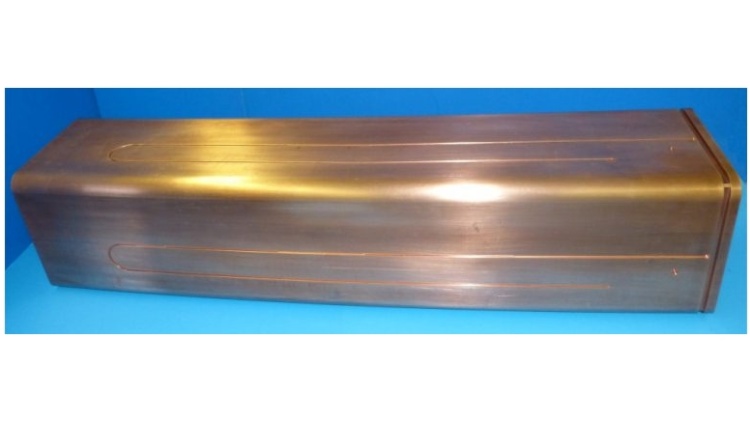

FOMTM – Application of fibre optical thermal monitoring at CC-billet and slab mould for improved process control and product quality

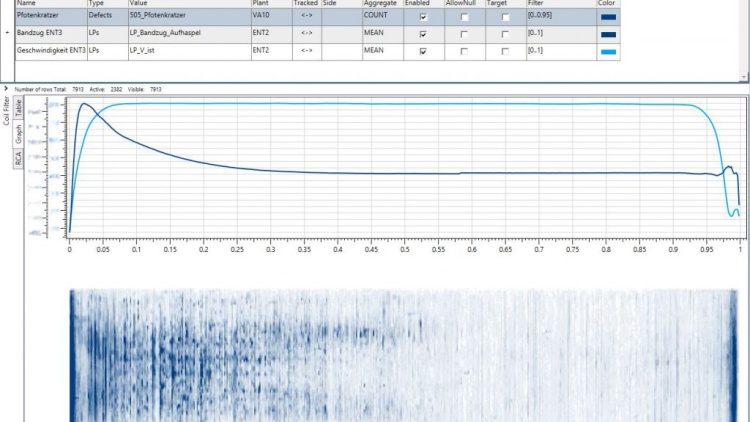

EvalHD – High resolution process data for quality assessment

IConSys – Improved quality management in flat steel production