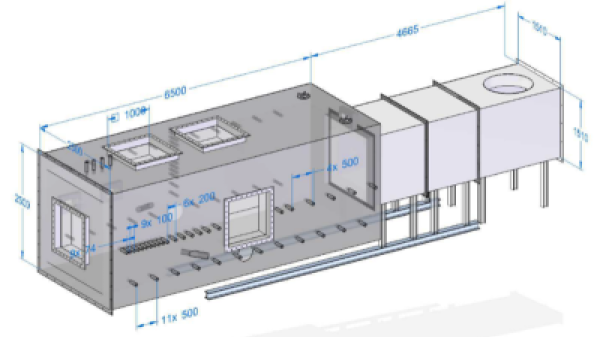

1 MW pilot plant

Your goals:

Examination of burners, components and devices

- under operating conditions

- in trial operation with process and metallurgical gases from the factory network

- with defined preheated combustion air and / or fuel gas

- with controlled furnace room temperature by heat sink

- with a defined atmosphere in near stoichiometry strongly over- or under-stoichiometric operation

- with high-resolution measurement of the reaction sequence in the area of the flame

Our portfolio:

- Flexible burner tests on own test facility

- Connections up to 1 MW

- Electrical connection: up to 3 x 50 kW (400 V, 125 A)

- Combustion gases: natural gas, blast furnace gas, coke gas

- Technical gases: Oxygen, nitrogen, H2 up to 60 % by means of coke oven gas, 100 % H2 possible via cylinders

- Combustion air preheating up to 1,100 ° C

- Fuel gas preheating up to 500 ° C

- Burnout measurements in flame

- Local analysis measurements via flexible probes (O2, CO, CO2, NOX, T, … ..)

- Flexible, digital measurement acquisition

- Photo and video documentation (e.g. UV camera)

Your contact person

32 Dr.-Ing. Bernhart Stranzinger

+49 211 98492-366

bernhart.stranzinger_at_bfi.de