CO2 reduction and energy efficiency

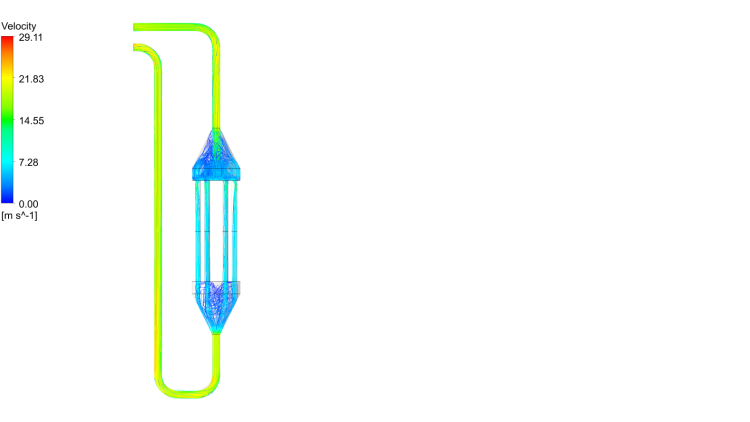

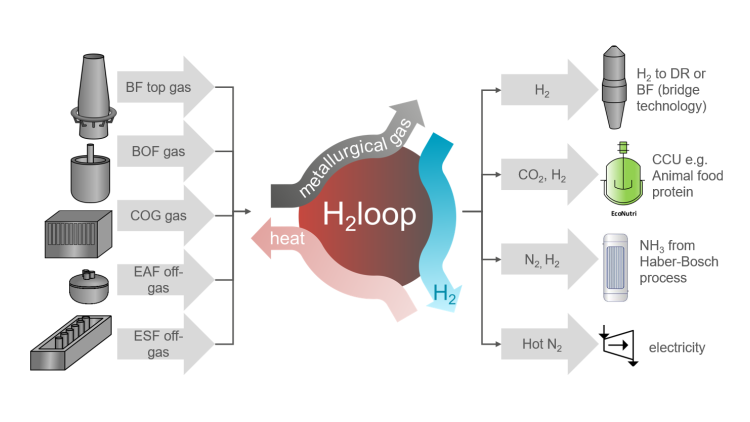

H2loop - Sustainable decarbonisation of integrated steel plants by hydrogen production from chemical looping

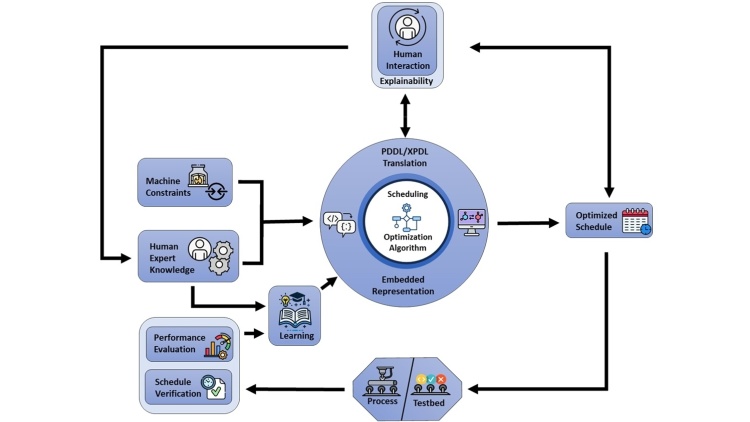

DeepScheduling - Explainable AI and Human-Centric Learning Solution Framework for Industrial Scheduling Optimization

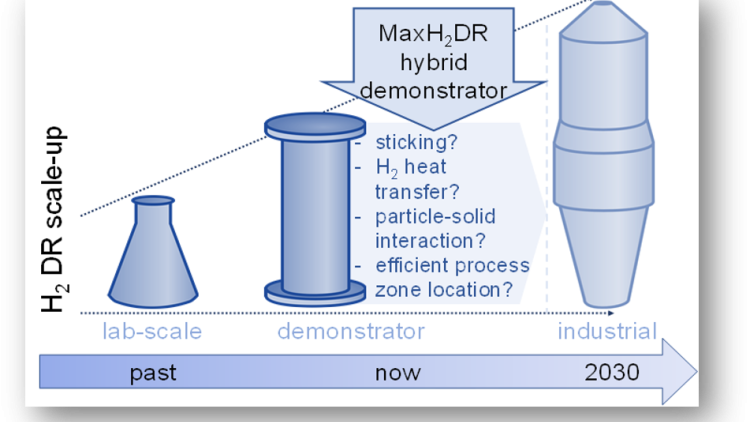

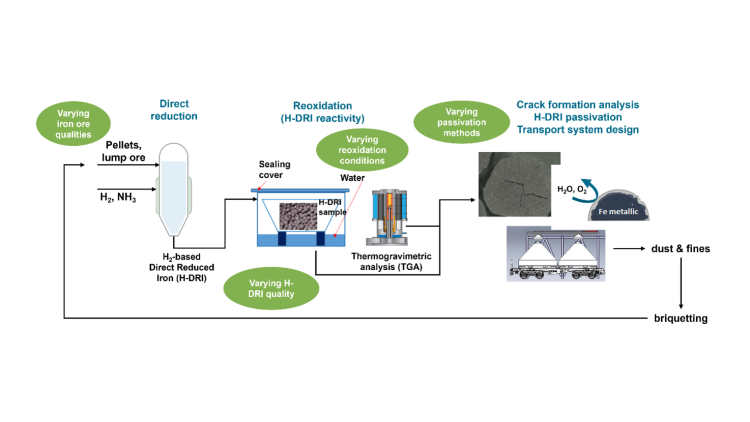

Safe H-DRI - Safe transport of DRI from H2-based direct reduction considering quality-related H-DRI reactivity, stability, the efficiency of passivation methods and health and recycling aspects

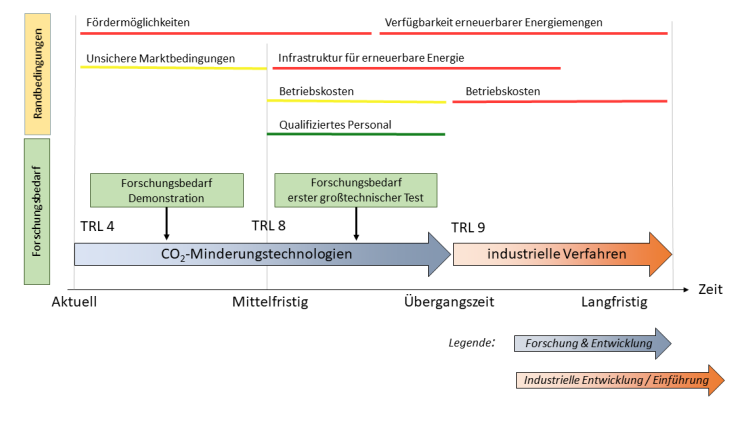

SCI4climate.NRW - Scientific support of the climate-neutral transformation of industry

H2TransBF2030 - Minimisation of CO2 Emissions from the BF by hydrogen containing injectants and use of HBI during transition to new Ironmaking processes until 2030

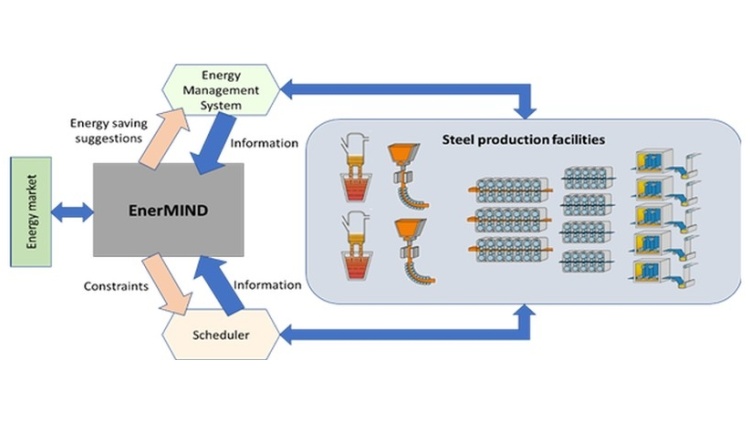

SynErgie3 - Synchronized and energy-adaptive production technology for the flexible alignment of industrial processes to a fluctuating energy supply

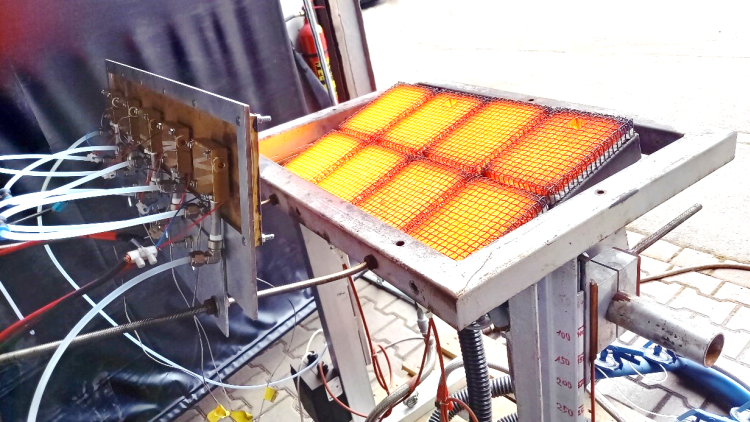

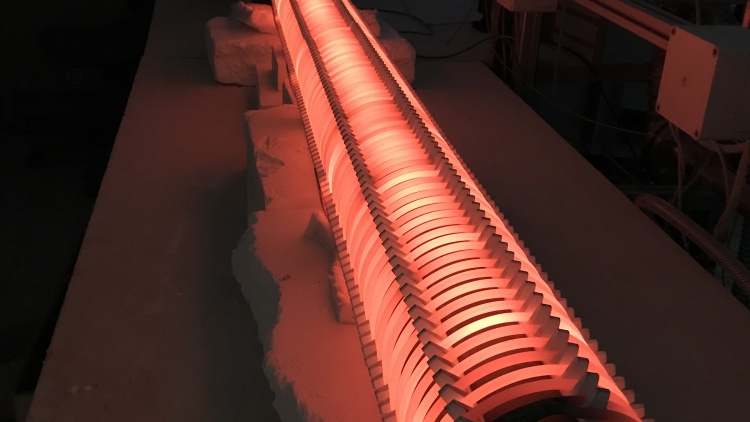

H2-HotRoll - Avoidance of CO2 emissions in the steel industry by utilizing of hydrogen in continuous thermoprocess plants on the example of reheating furnaces

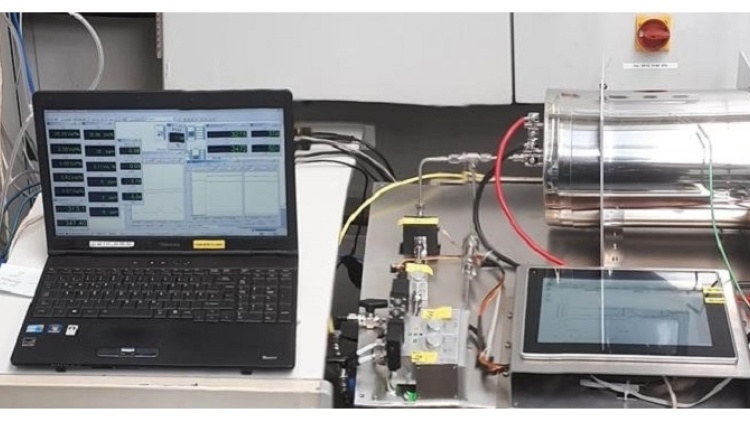

SelGaKat - Method for increasing the energy efficiency by selective gas quality measurement taking into account the hydrogen content using a catalytic reference combustion chamber

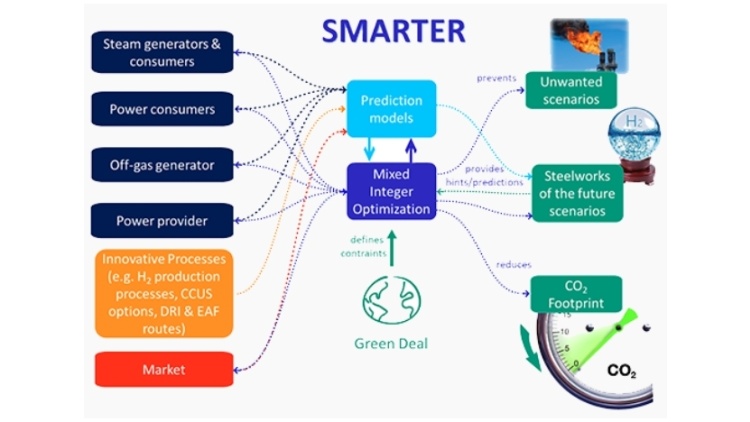

AMIGDALA - Alliance for Modelling Industries towards the Green Deal’s objectives And circuLArity

BeRefCo - Operational testing of a reflective furnace wall coating and determination of the influence on energy requirements and CO2 emissions

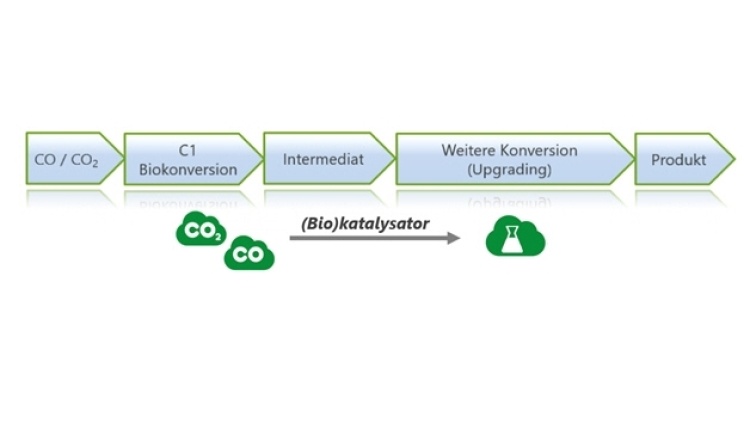

MemKoWI – Membrane processes for the separation of carbon dioxide and hydrogen from industrial gases

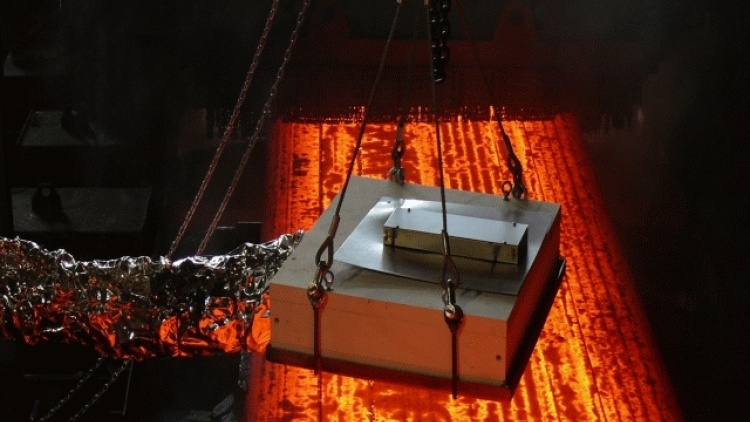

DRI-smelter – Novel process for the production of pig iron by melting sponge iron from direct reduction in a DRI smelter

HYDREAMS - Clean hydrogen combustion and digital tools for reheating and heat treatment for steel

DissHEAT – Dissemination of the heating technology research results for emission minimization and process optimization towards todays fossil-free heating agenda

InnoGuss – Development of innovative transformation paths for the decarbonization of the foundry industry in NRW

AeroRef – Reduction of energy demand in heating furnaces by new combination of aerogel and refractory

VEIK – Improvement of heat treatment and heating in industrial furnaces by new innovative ceramic hot gas fans

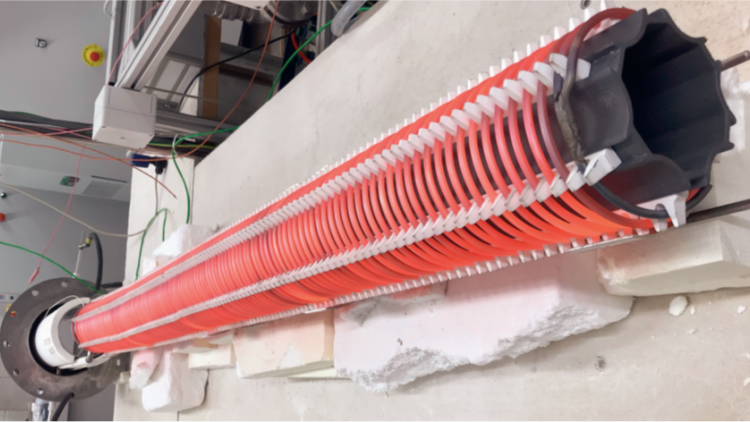

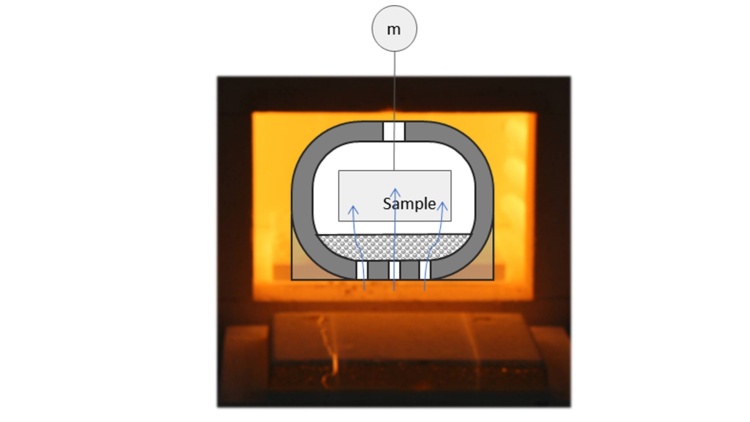

H2-DisTherPro – Avoidance of CO2 emissions in the steel industry by utilzing of hydrogen in batch-type thermoprocess plants on the example of batch annealing

H2Stahl – Hydrogen technologies for a successive decarbonisation of the steel industry

InnoKon – Innovative non-stick surface to increase the service life of oxygen lances on the converter

ReflexRolle – Development of a reflecting, anti-adhesive Coating for furnace rollers

REDERS – Reduced CO2 emissions by increasing the recycling rate in steel production

Digitisation and process measurement technology

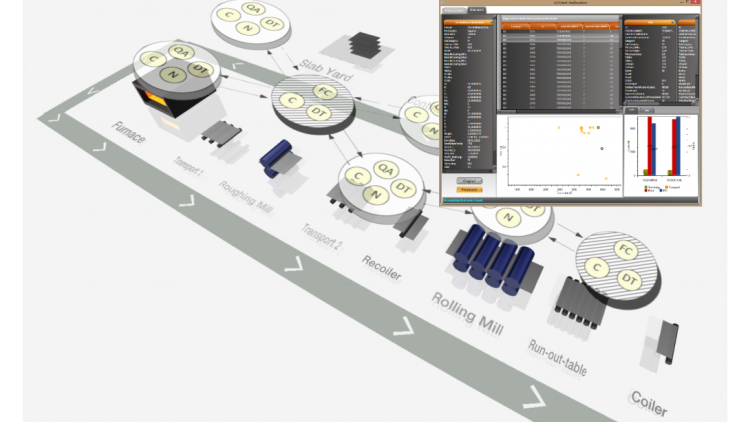

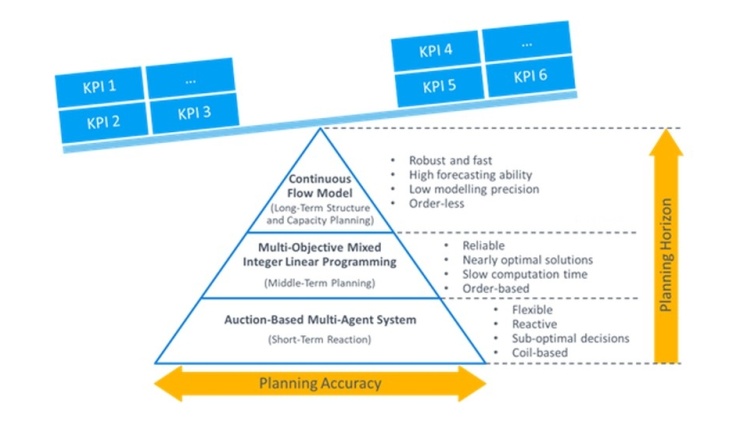

AgiFlex - Agent-based models minimizing carbon usage in flexible and efficient future integrated steelworks

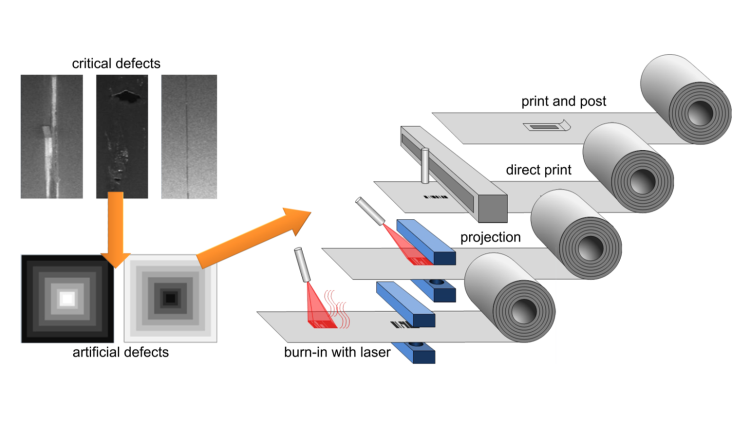

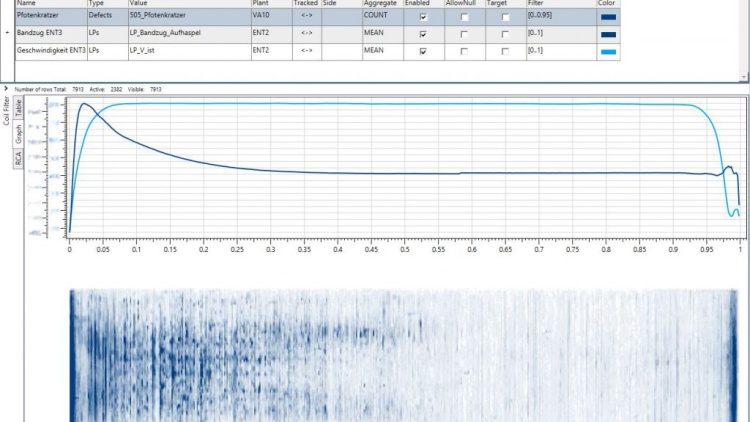

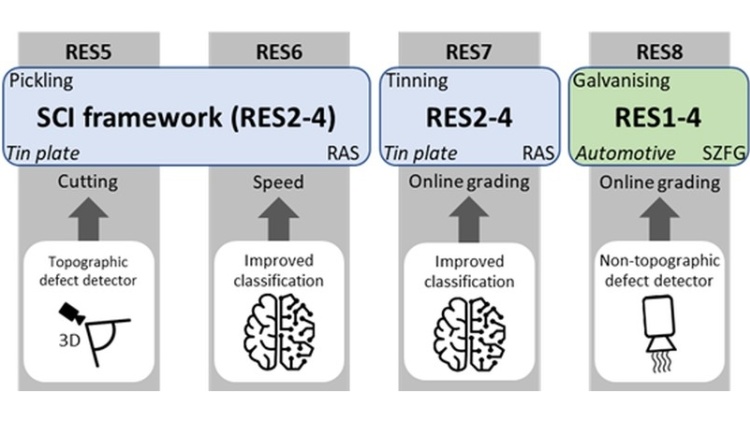

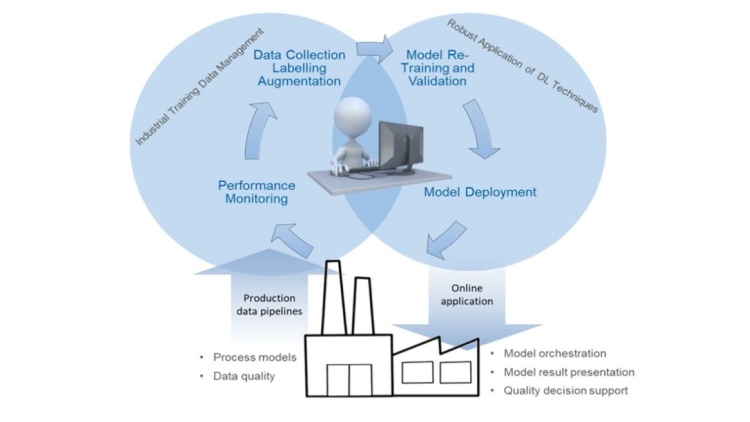

SufConInspect - Enabling zero-defect manufacturing for flat steel production by means of optimized inspection results and a new level of online surface quality control

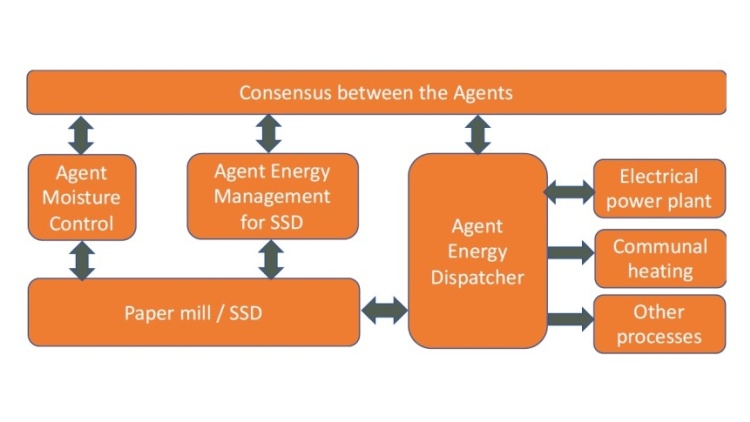

SteamDry - Superheated steam drying for sustainable and recyclable web-like materials

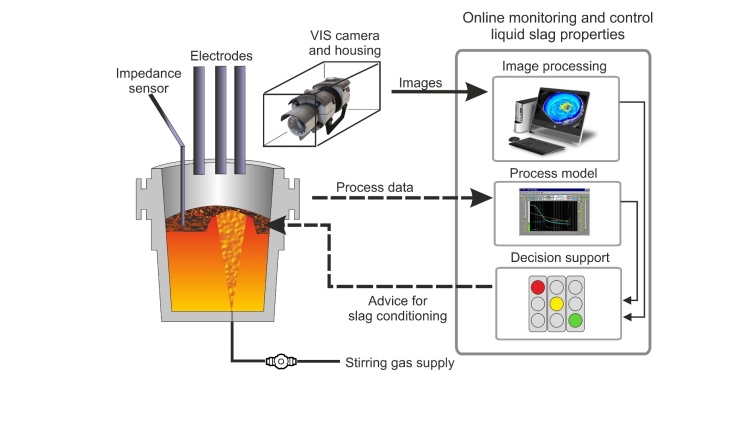

OptDeslag - Increased yield and enhanced steel quality by improved deslagging and slag conditioning

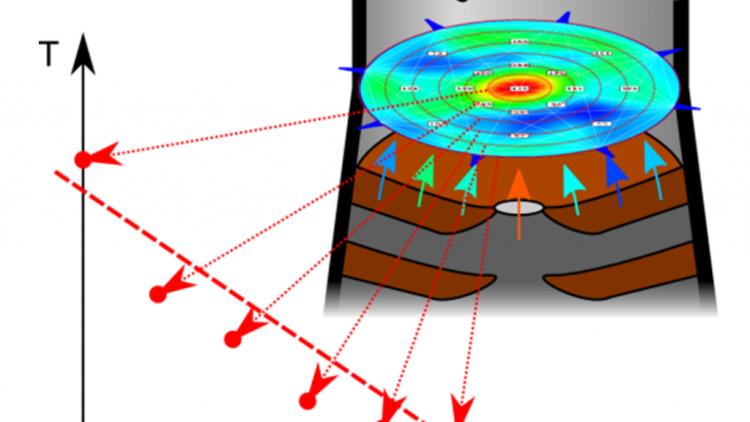

DynStir - Dynamic stirring for improvement of energy efficiency in secondary steelmaking

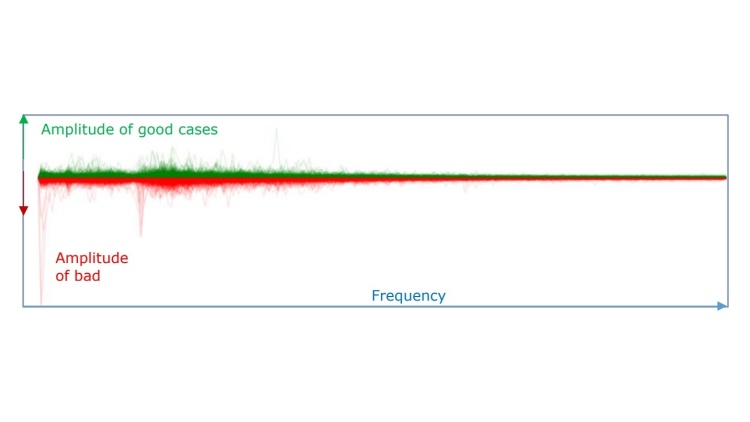

SitErk - Continuous optimisation of processes and systems in industrial production through the automatic recognition of process situations based on high-resolution system and process data

ALCHIMIA - Data and decentralized Artificial intelligence for a competitive and green European metallurgy industry

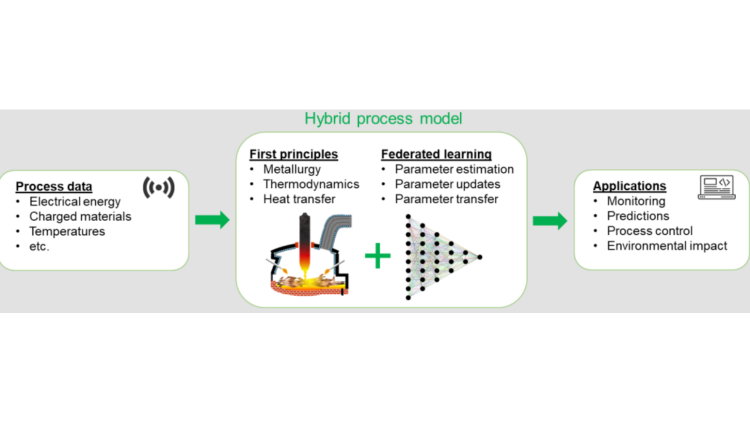

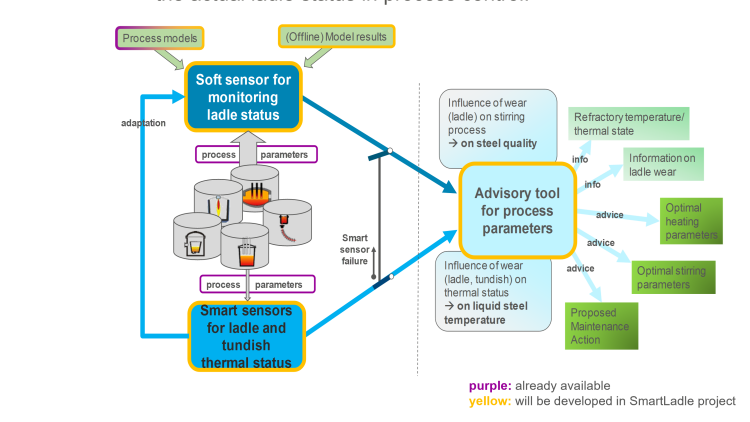

SmartLadle - Smart consideration of actual ladle status monitored by novel sensors for secondary metallurgy process parameters and ladle maintenance strategies

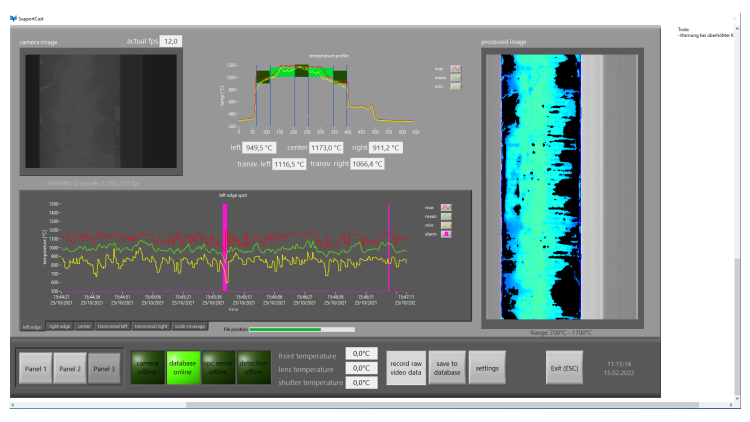

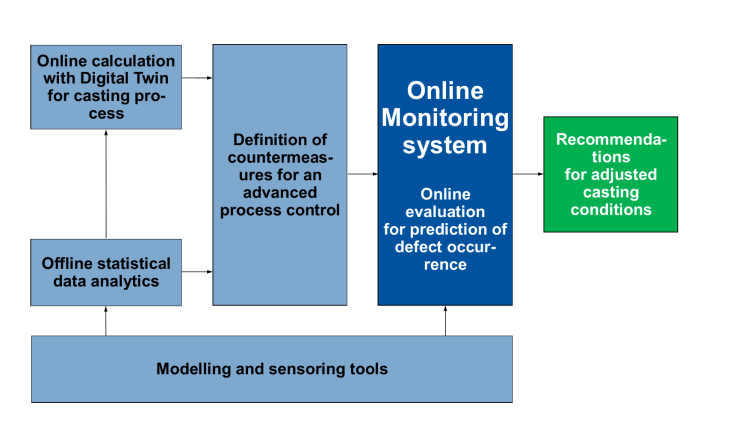

SupportCast - Supporting Control by Inspection of Surface Quality and Segregation on Cast Products through integration of Novel Online Monitoring and Advanced Modelling into an Accessible Cloud Access Platform

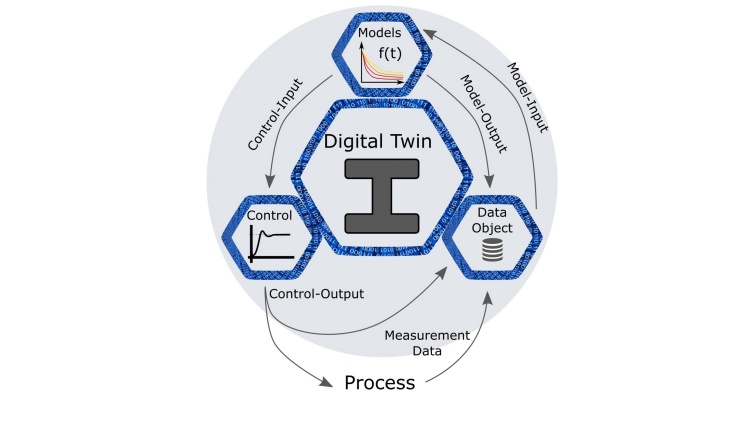

OpConDigiCast - Digital Twin Technology for Comprehensive Simulation, Optimization and Control of Continuous Steel Casting Process

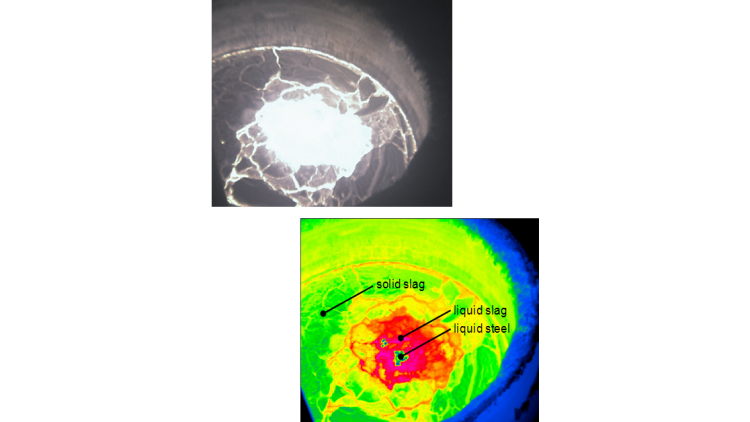

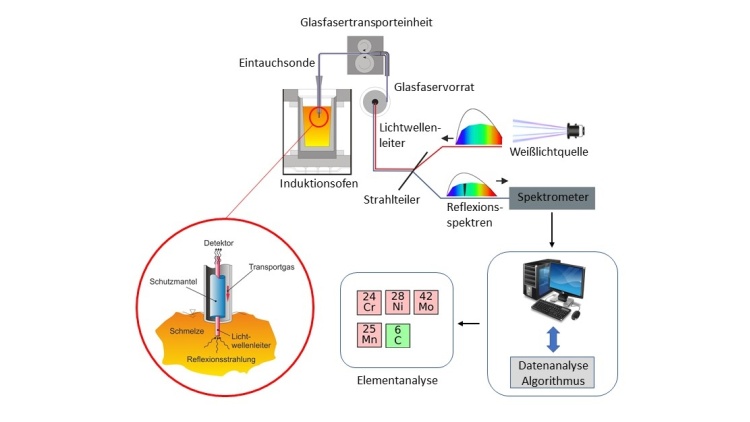

OMiAS - Optical online measurement method for in-situ analysis of the chemical composition of a steel melt during liquid steel production

CAPRI - Kognitive Automatisierungsplattform für die digitale Transformation der europäischen PRozess-Industrie

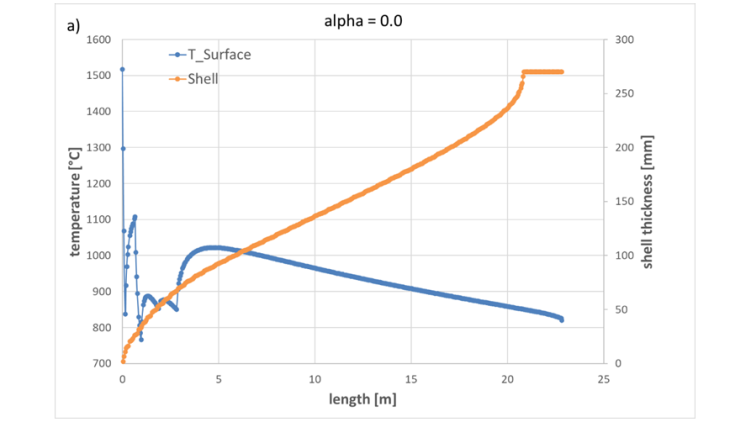

ConSolCast – Comprehensive modelling, monitoring and control of solidifcation for optimisation of continuous casting process

TrackOpt - TrackOpt - Consistent ladle tracking for optimization of steel plant logistics and product quality

DynReAct_PDP - Roll-out refinement of production scheduling through dynamic product routing, considering real-time plant monitoring and optimal reaction strategies

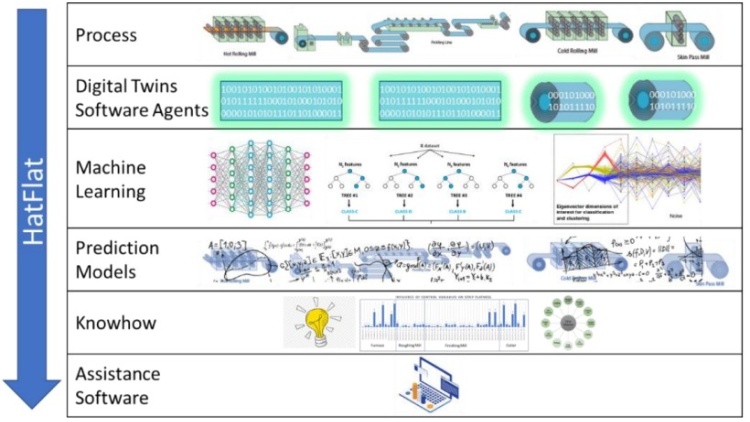

HatFlat - Holistic Assistance for Cross-Process Analysis and Prediction of Strip and Plate Flatness

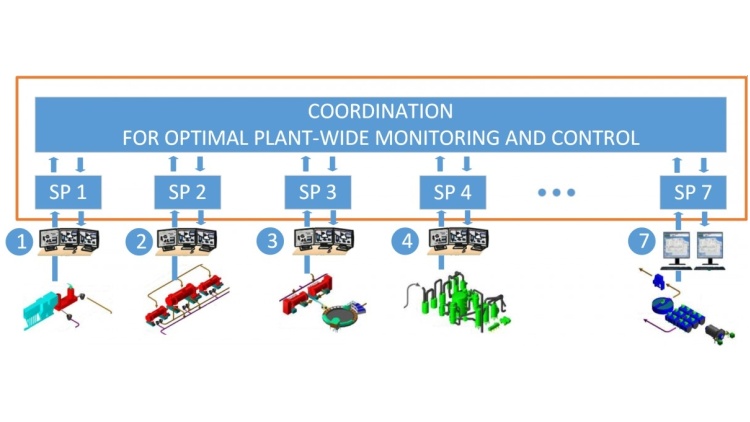

s-X-AIPI – self-X Artificial Intelligence for European Process Industry digital transformation

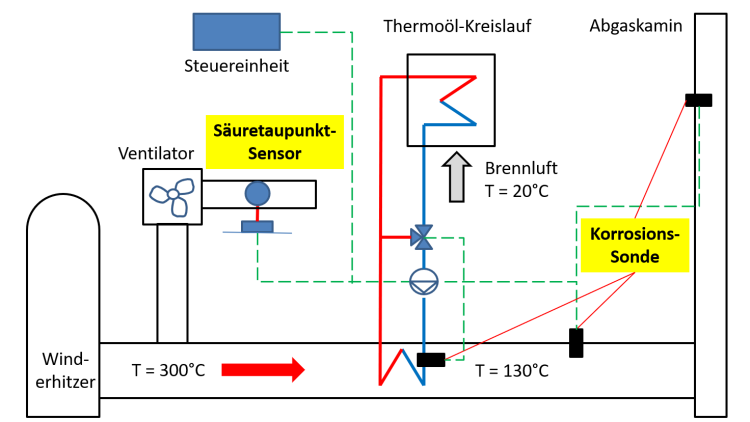

SafeDewPoint – Acid dew point and corrosion sensors for dynamic waste heat recovery from steel mill flue gases

MACO Pilot – Optimierung der Online-Konzentrations-Überwachung und Regelung an Edelstahl-Mischsäurebeizanlagen

DeepQuality – Use of robust deep learning methods for the automatic quality assessment of steel products

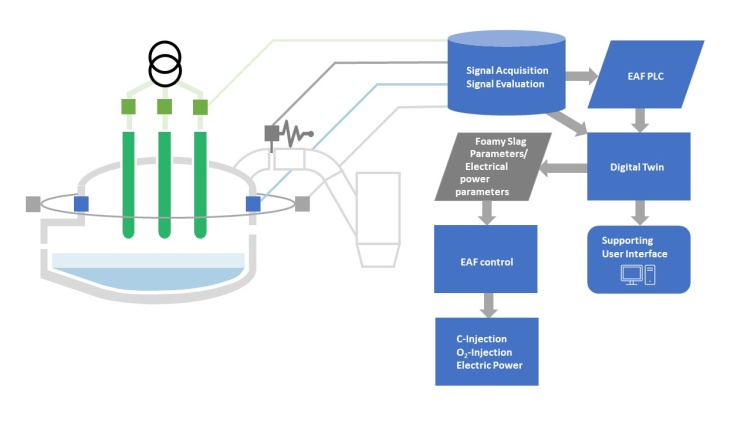

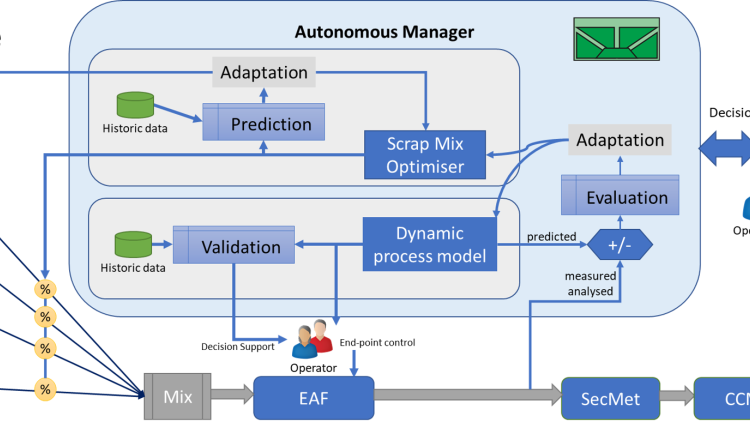

MeltCon – Determining process conditions for online monitoring of temperature and carbon content in the electric arc furnace to optimise end point control

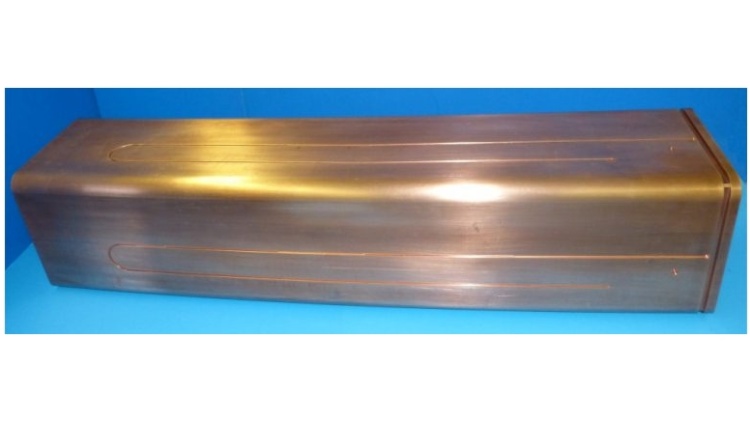

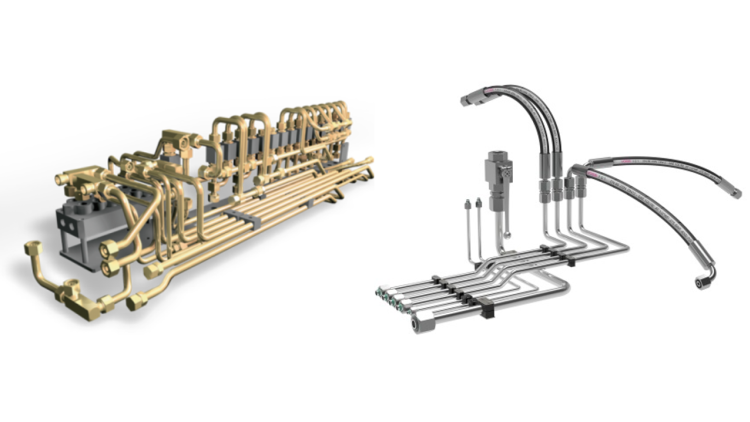

FOMTM – Application of fibre optical thermal monitoring at CC-billet and slab mould for improved process control and product quality

Circular economy

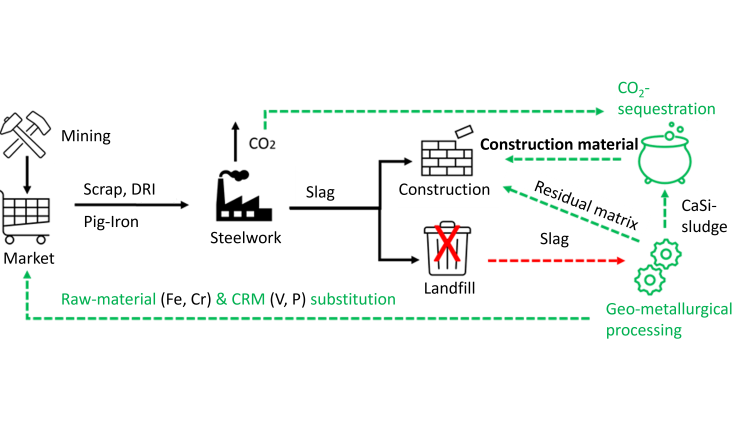

GeoCRM - Geometallurgical processing of steelmaking slag for recycling critical raw materials and CO2 binding

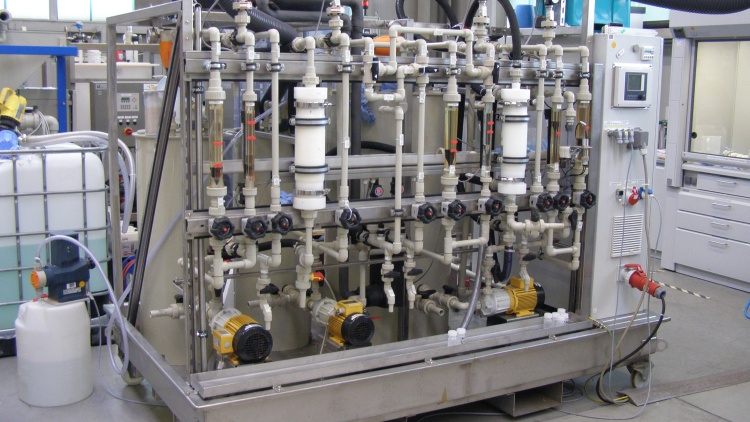

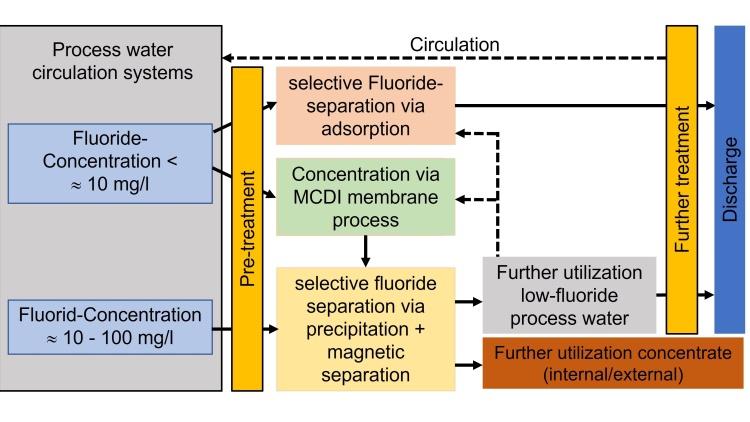

FluoridSelektiv - Process development for selective fluoride separation from industrial process water

ZinkAtline - Development of an atline measuring method for rapid analysis of the total zinc content in process water

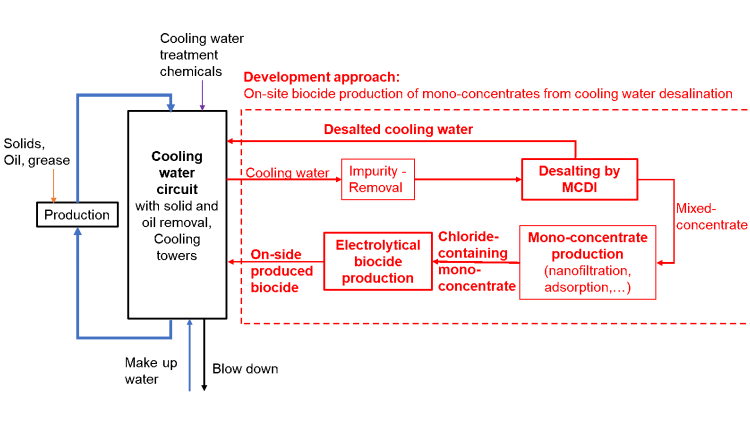

Konzentrat-Biozid - Development of a reliable process for cooling water desalination based on membrane-assisted capacitive deionization with production of monoconcentrates

WEISS_4PN - Integrative application of innovations and digital cooling capacity management to reduce water consumption in steel production – Sub-project 2: Forecast of operational scenarios of cooling circuits due to climate-related bottlenecks and determination of disturbing influences when using the Capacitive Deionization (MCDI)

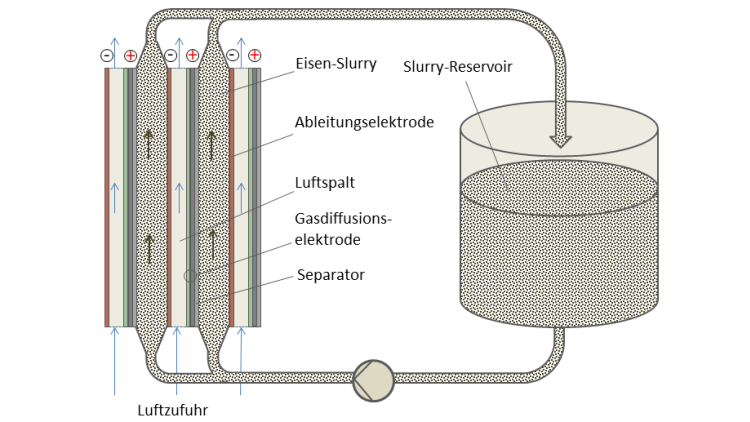

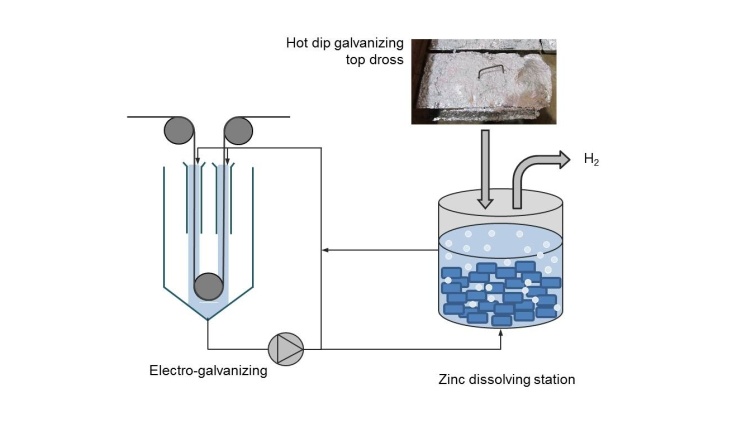

ZHyRON - Valorisation of iron-rich & Zinc-containing steelmaking by-products via HYdrogen-based ReductiON

IndiWater - Independent industrial water supply by digitalization, simulation and innovative treatment technologies

TransZeroWaste - Upgrading of low-quality iron ores and mill scale with low carbon technologies

CORNERSTONE - Combined technologies for water, energy and solute recovery from industrial process streams

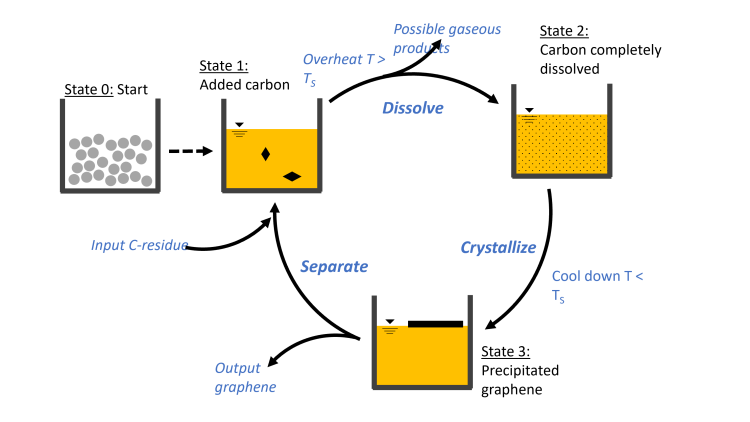

RekCarb 2 – Recrystallisation of Carbon containing Residuals to Graphene-Nano-Platelets

MiningWater – Mining water recovery using innovative technologies for saving fresh water

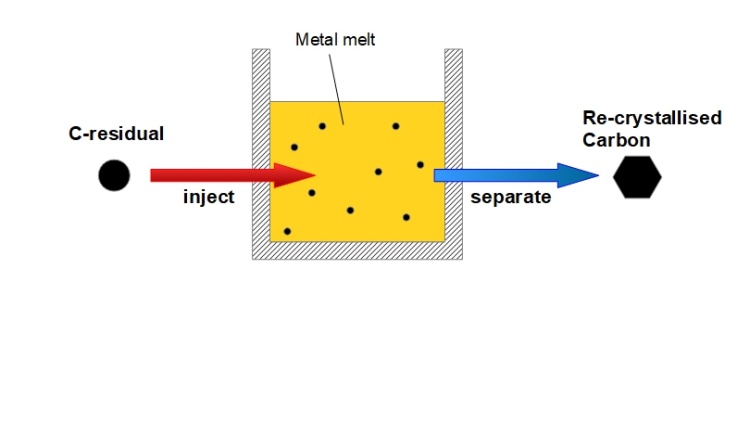

RekCarb – Upcycle of carbon containing residuals and by-products through recrystallisation in molten metals

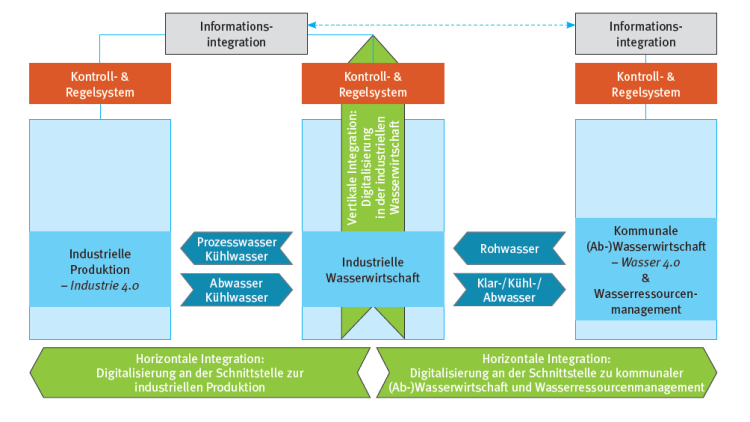

DynaWater4.0 – Dynamic value creation networks through digital collaboration between industrial water management and production

SPOTVIEW – Sustainable Processes and Optimized Technologies for Industrially Efficient Water Usage in steel, dairy or pulp and paper industry

HiJetRod Pilot – Resource-efficient hydromechanical descaling system for wire coils

INSPIREWATER – Innovative Solutions in the Process Industry for next generation Resource Efficient Water management

WEISS – Efficient operation of cooling water circuits by integrated desalination at the example of the steel industry

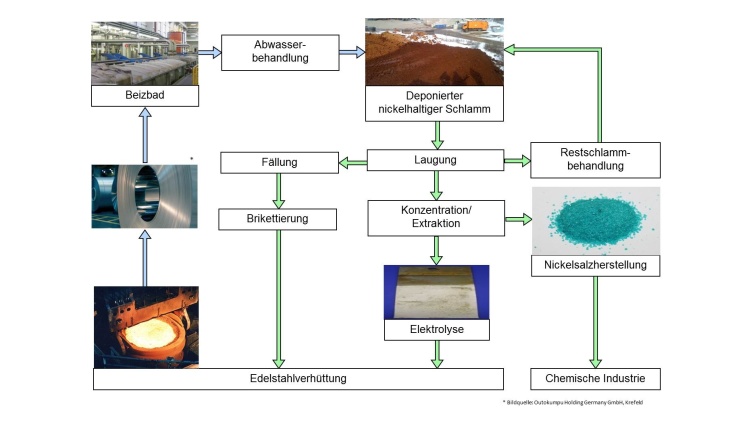

UrbanNickel – Recovery and recycling of nickel from deposited neutralization sludge of the stainless steel industry

Schwermetall-Adsorber – Development of an adsorption material for selective heavy metal removal from industrial process waters

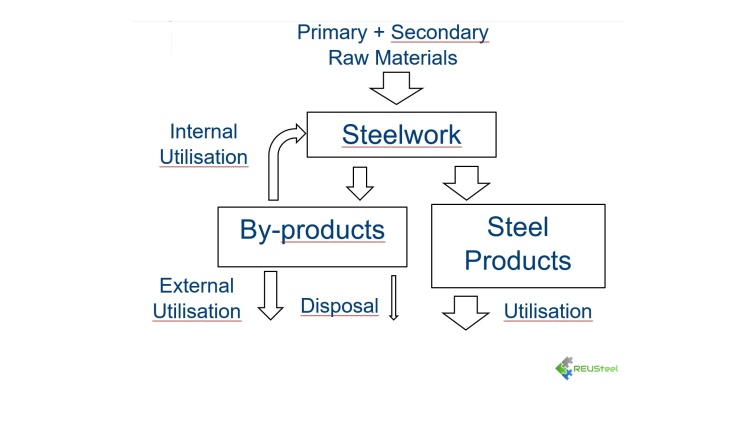

REUSteel – Dissemination of results from European research projects on the reuse and recycling of by-products in the steel sector

Process optimisation

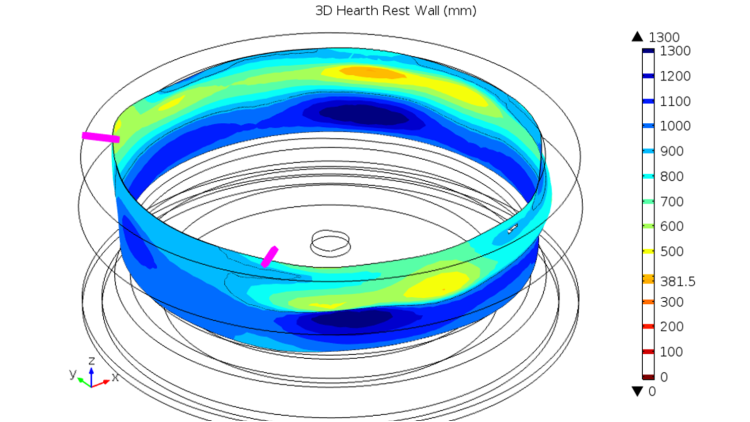

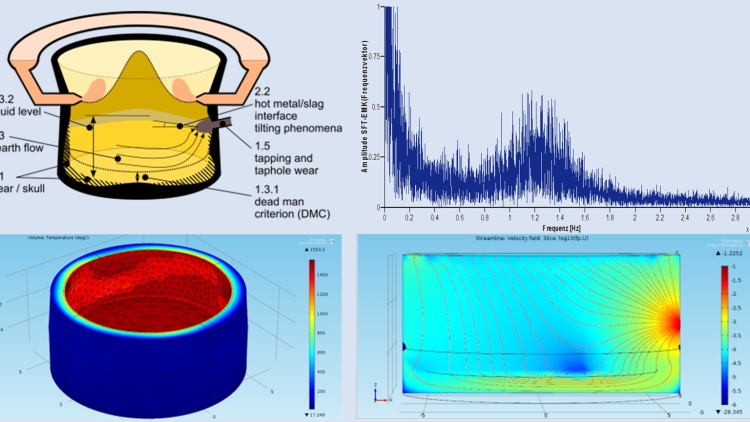

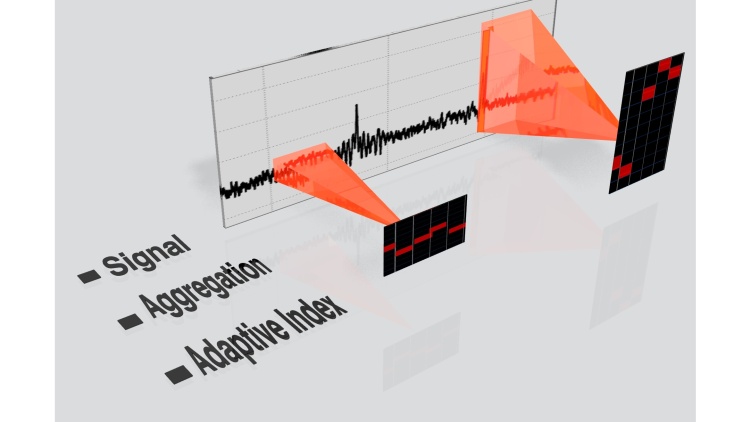

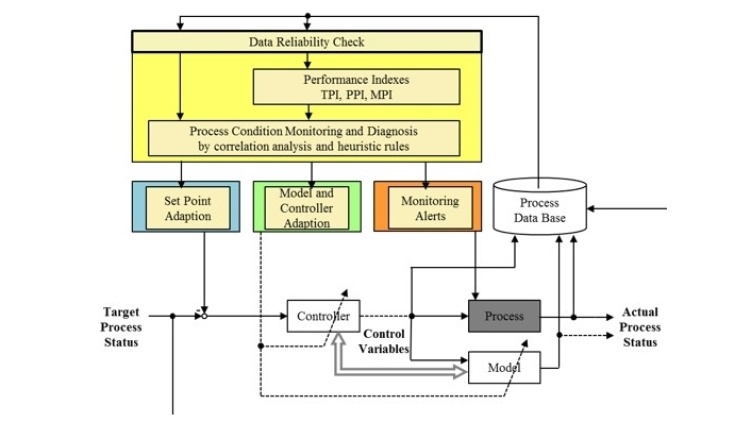

PerMonLiSt - Continuous performance monitoring and calibration of model and control functions for liquid steelmaking processes

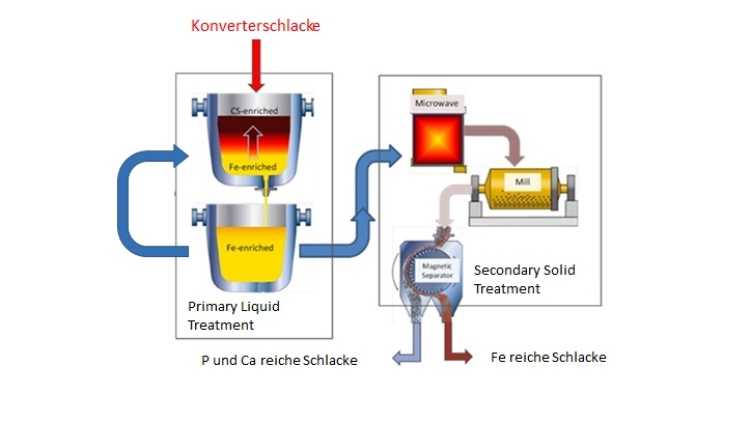

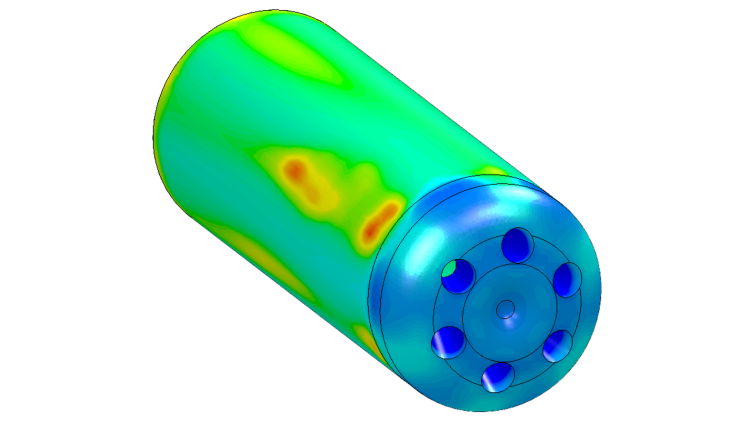

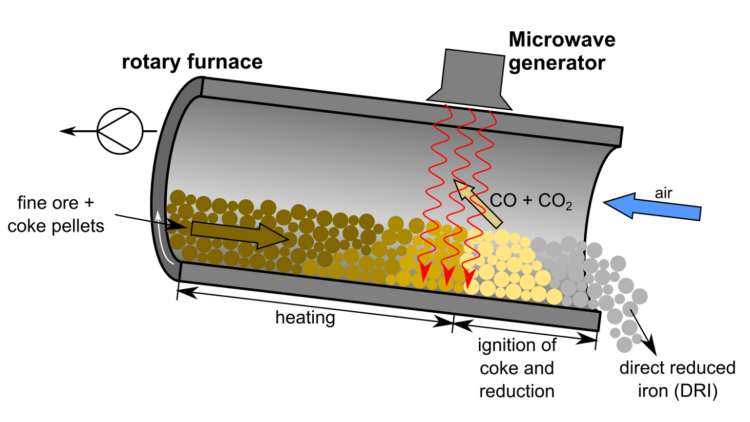

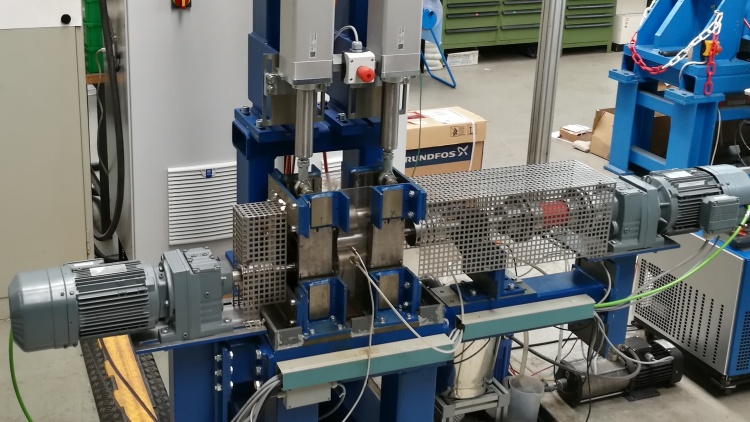

DESTINY - Development of an Efficient microwave System for material Transformation in energy INtensive processes for an improved Yield

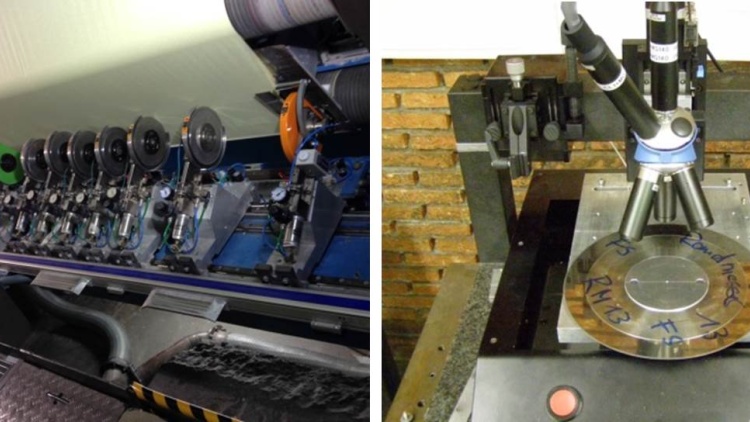

Rolloilfree II - Transfer of aqueous oil free lubricants into steel cold rolling practice

TailoredZA - Tailored structure of multi-layer zinc alloy coatings to improve forming and corrosion protection properties

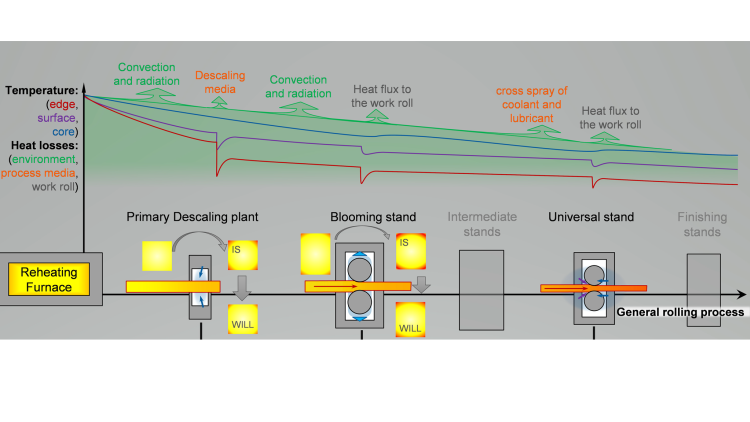

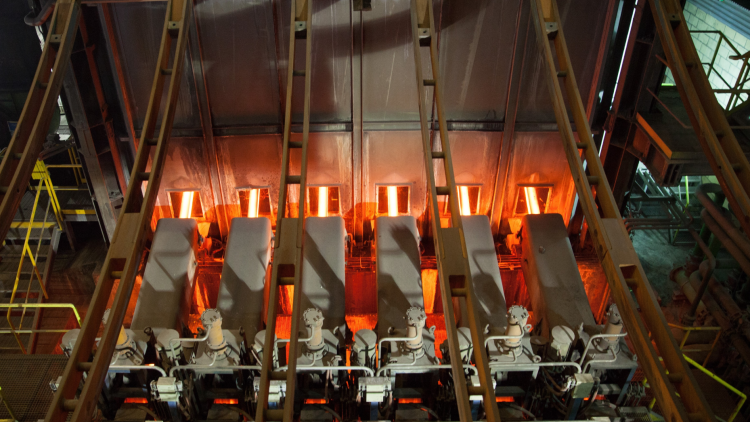

SunShine – Sustainable new casting and rolling process monitoring / sensoring approach aimed at proper surface quality and shape in flat and long products

REVaMP – Retrofitting of sensors and optimization tools for the efficient use of variable input materials in the metal-producing industry

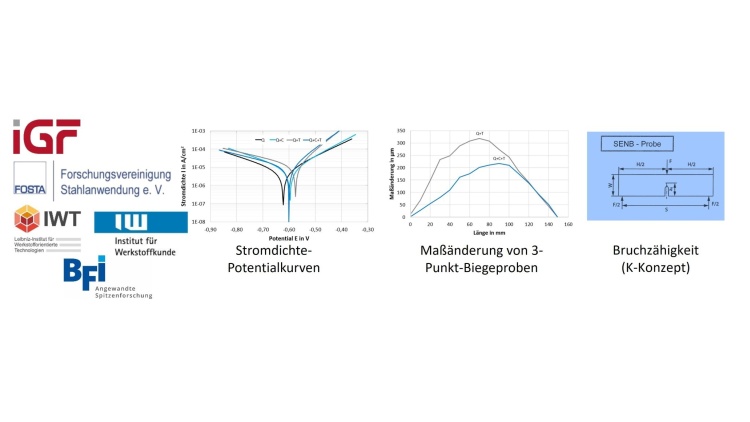

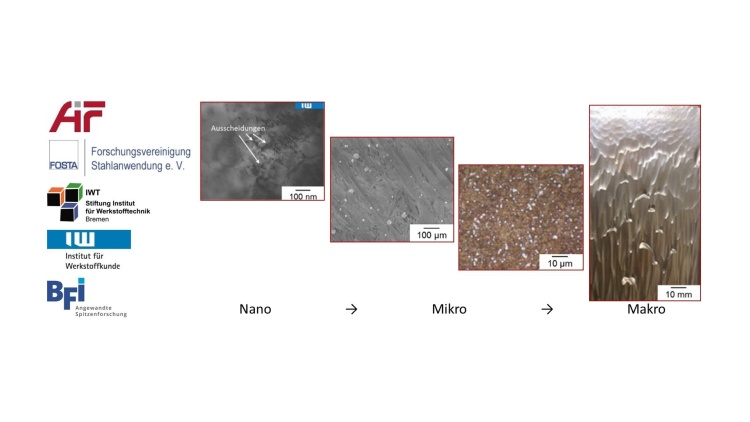

Nanocarbides II – Influence of deep cryogenic treatment on distortion, corrosion and fracture toughness

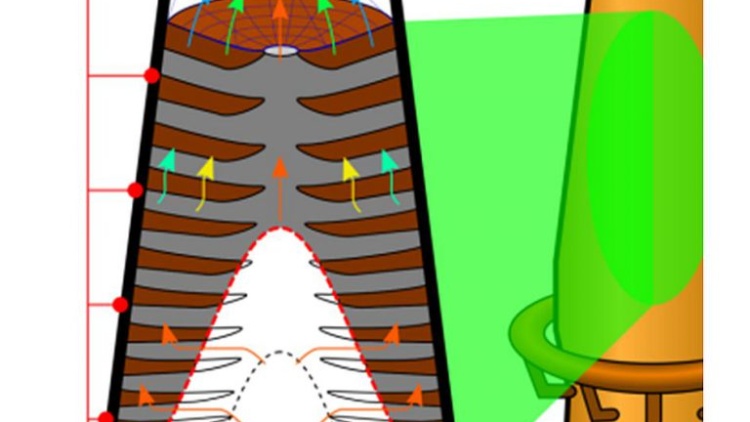

MinSiDeg - Minimisation of sinter degradation between sinter plant and blast furnace exploiting embedded real-time analytics

RealTimeCastSupport- Embedded real-time analysis of continuous casting for machine-supported quality optimisation

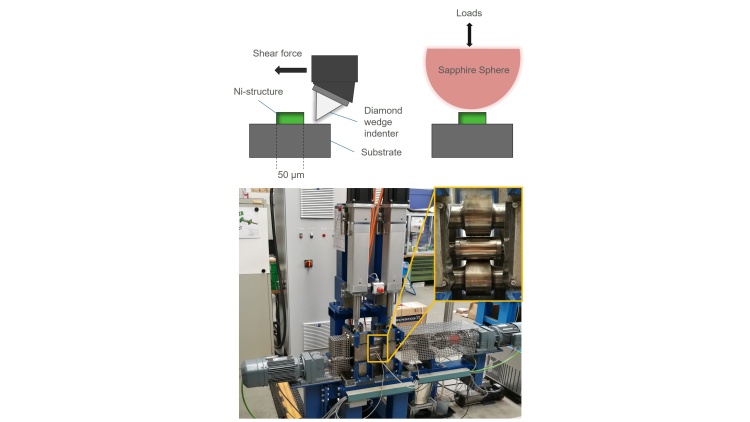

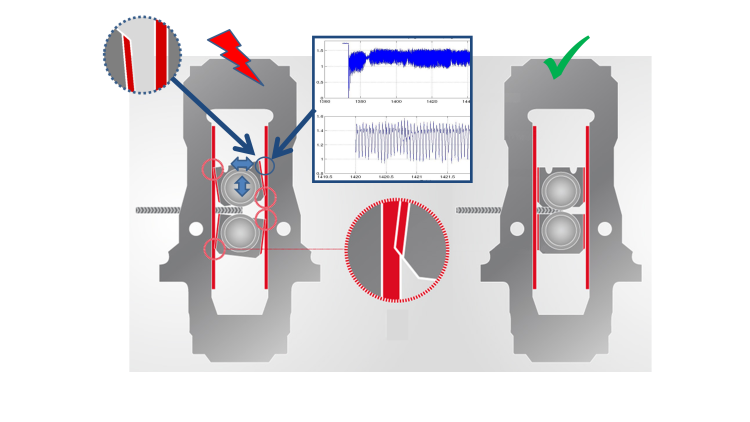

Reduwearguid – Reduction of wear on guiding components in hot rolling finishing and coiling line for improved service life time and product surface quality

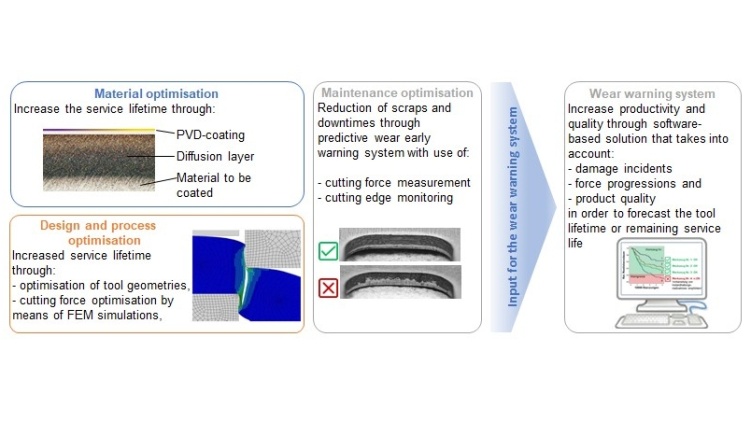

IntellCutProcess – Optimisation of cutting processes using intelligent cutting tools

iSLAG – Optimising slag recycling through on-line characterization devices and intelligent decision support systems

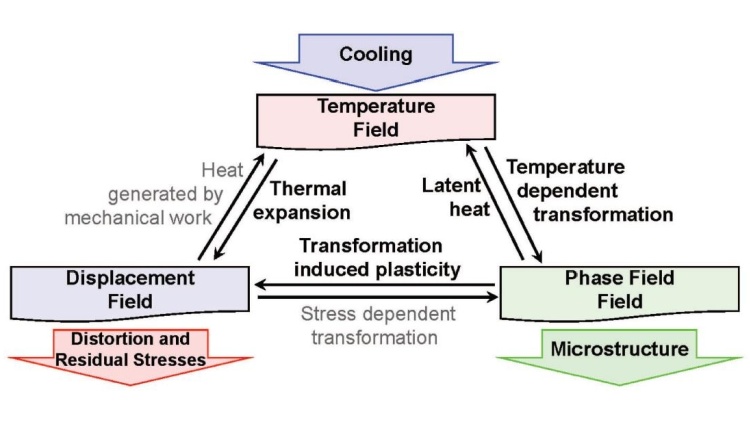

PROTEUS-RS – Long Product Quality Optimisation through Enhancement and Utilisation of Residual Stress minimising Process Strategies

non stick-FiReNi – Development of stress compatible coating systems for the optimization of cutting tools

Infire – Strategy to increase the hot strip rolling performance in terms of surface quality, final properties and reproducibility

CoolCut – Development of an innovative industrial cutting technique for highly abrasive web-type material

Nanocarbides – Enhancing technological properties of tool steels by cryogenic treatment

TriboCoat – Optimization of highly stressed sliding contacts by the use of innovative coating and surface concepts

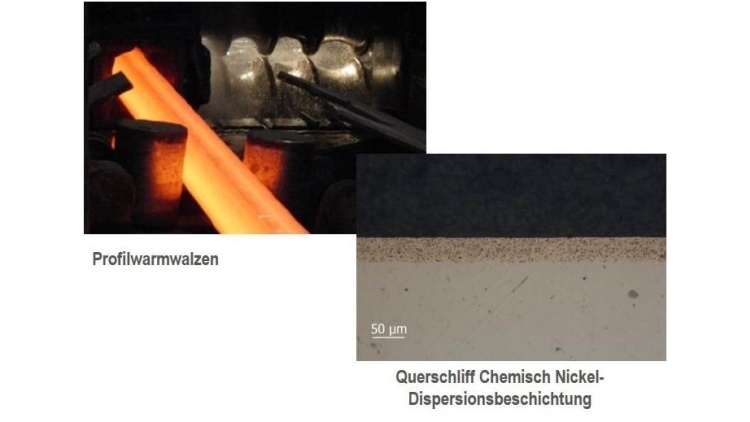

Mikrokaltschmieden – Application of machine hammer peening on profiled rolls for wear reduction and improvement of the surface quality and dimensional stability of hot-rolled profiles

InnoZun – Development of a process combination to improve the surface quality of pickled stainless steel strip using additives for secondary scale conditioning in combination with new innovative descaling and pickling processes

NanoZunKonLub – Application of nanoparticle enhanced coatings for scale conditioning in die forging processes in order to optimize the tribological system

HiperScale – High performance hot rolling process through steel grade-dependent influencing of the scale formation and flexible descaling control

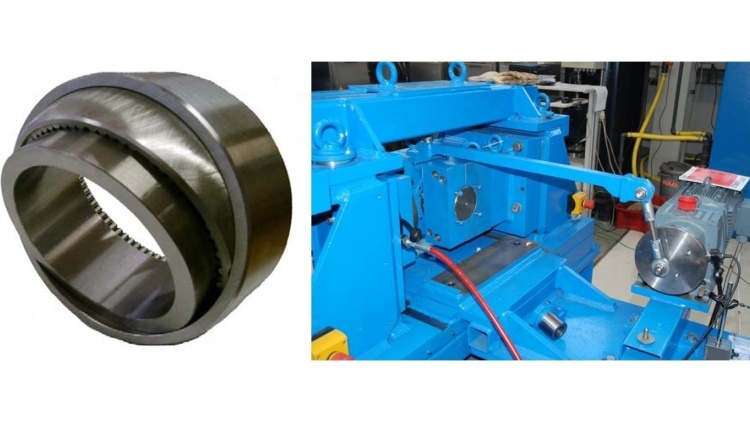

DissTec - Valorisation and dissemination of technologies for measurement, modelling and control in secondary metallurgy

HEROLL – Prevention of hydrogen embrittlement of cold rolling rolls by improved work roll material and lubricant configuration