CAPRI - Kognitive Automatisierungsplattform für die digitale Transformation der europäischen PRozess-Industrie

Initial situation:

The Process Industry transforms raw material feedstock into intermediate and end-user products and so represents the starting of almost all value chains. Process industry is the industry of fluid flows (continuous or batch), pipes connecting pumps, tanks or reactors, irreversible manufacturing process, regulatory control (vs logic sequential control in discrete manufacturing) of unitary operations with high restrictions in terms of Real Time control. The Process Industry sectors covered in SPIRE PPP represent a major part of the manufacturing base in Europe (EU27), including more than 450,000 individual enterprises. They have over 6.8 million employees, generating more than 1,600 billion € turnover. Therefore, they represent a 20% of employment and turnover of European industry. Globally, these sectors represent the 37% of industry energy spent and 15% of emissions. SPIRE comprises cement, ceramics, chemicals, engineering, minerals and ores, non-ferrous metals (NFM), iron & steel and water sectors, several being world-leading sectors operating from Europe. The process industry sector has also a high dependency of raw materials not readily available in the EU.

Project targets:

The overall objective of CAPRI is to develop, test and experiment an innovative Cognitive Automation Platform (CAP) for achieving Process Industry Digital Transformation enabled by Cognitive Solutions that provide existing process industries flexibility of operation, improvement of performance across different indicators (KPIs) and state of the art quality control of its products and intermediate flows. CAPRI tries to deliver a series of challenges that Process Industry faces such as: Feedstock Variations, Energy Efficiency, Flexibility, Traceability, Energy and Raw Materials and Quality, by developing and testing Cognitive solutions technology interacting with the CAP platform.

Innovative approaches:

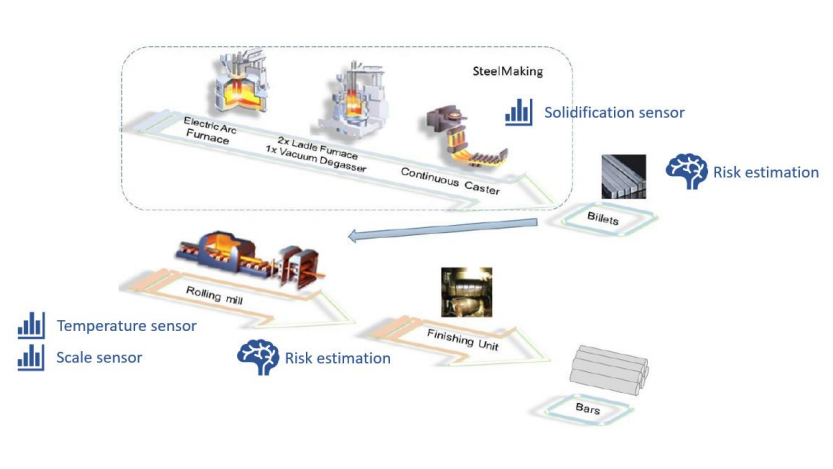

A real time simulation model of the continuous casting process of steel (and potentially other materials), providing detailed information on the temperature field and solidification front in the casting strands as well as the temperature profile, casting history and relevant properties from the previous liquid steelmaking processes for the billets cut at the end of the casting process.

Benefits for the industry:

The Cognitive Automation Platform has been conceived with modularity as a main principle, and this has been demonstrated with its Reference Implementation. Open-Source components in every layer can be combined according with a Lego-like approach, fulfilling the exposed data schema, making the architecture flexible and adaptable to the specific needs of the various application domains, enabling digital transformation in process industry.

Further information about the project: CAPRI

partners

Funding reference

Your contact person

47 Dr. Christoph Nölle

+49 211 98492-653

christoph.noelle_at_bfi.de