DeepScheduling - Explainable AI and Human-Centric Learning Solution Framework for Industrial Scheduling Optimization

Initial situation:

Stainless-steel products for aviation and aerospace require extremely precise process control during annealing, hardening, tempering, and quenching. Very narrow temperature windows of only a few kelvins must be maintained. Heating and cooling times of the ovens cause production stops, leading to low throughput and high energy costs. The production chain is complex, and different plants have varying capabilities, creating challenging constraints.

Project targets:

- Optimise the currently manual production schedule for demanding stainless-steel products

- Reduce unproductive oven times and increase efficiency

- Manage complex constraints from different plant properties

- Improve planning accuracy across multi-step production routes

Innovative approaches:

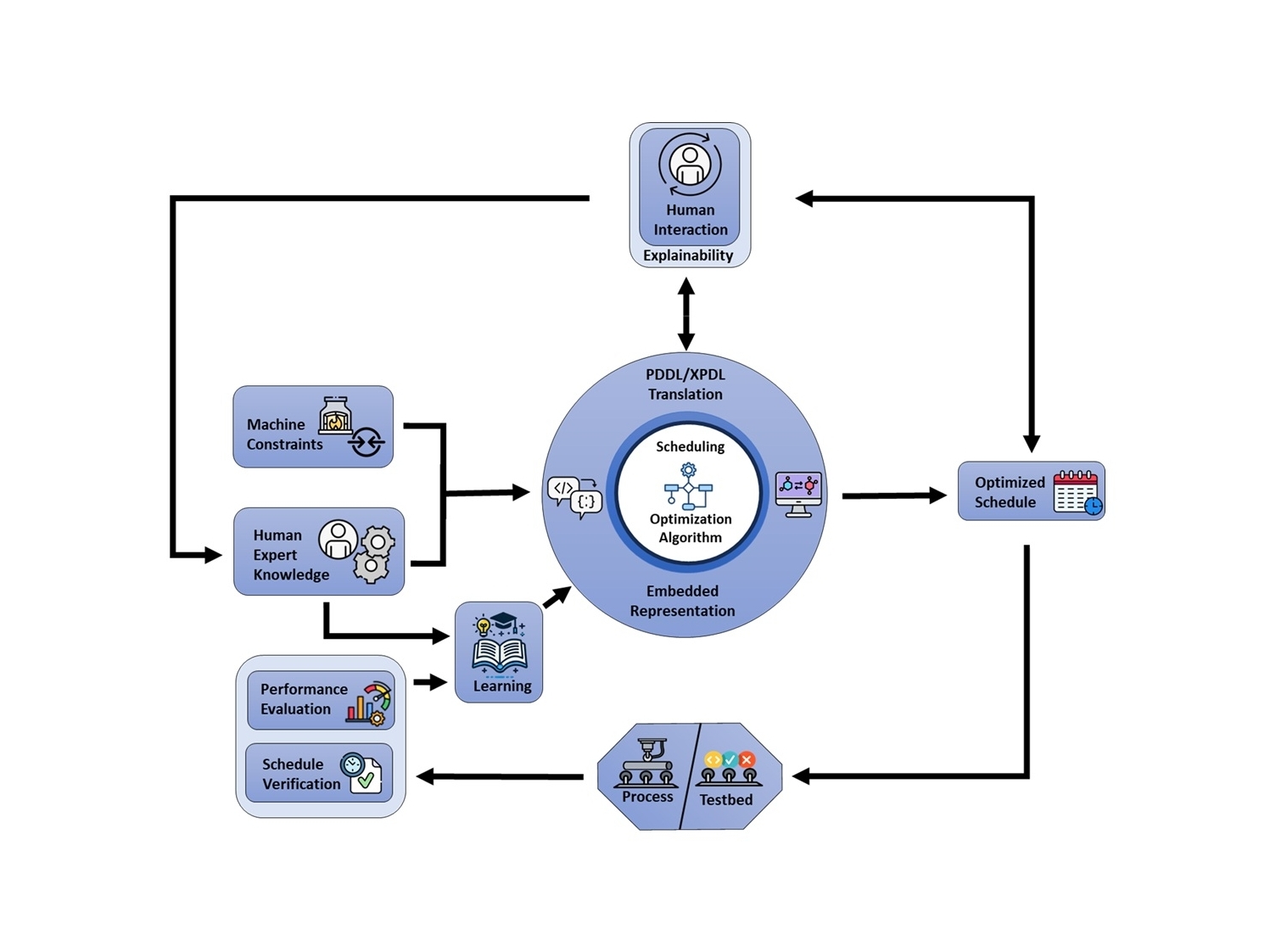

- Advanced optimization techniques (e.g., mixed-integer relaxation, lexicographic optimization, Cut Generation, Constraint Exchange)

- Modern AI methods such as agent-based auctions, PPO with expert knowledge, hybrid policy models, and Meta-Learning

Benefits for the industry:

- Higher production efficiency and reduced energy costs

- Reliable compliance with extremely tight process specifications

- More flexible and robust scheduling for complex production chains

- Improved competitiveness through data-driven scheduling tools

Funded by:

Project duration:

01.07.2025 - 31.12.2028

Further information:

partners

Funding reference

RFCS project no 101216553

Your contact person

38 Dr. Ahmad Rajabi

+49 211/98492-215

ahmad.rajabi_at_bfi.de