DynReAct_PDP - Roll-out refinement of production scheduling through dynamic product routing, considering real-time plant monitoring and optimal reaction strategies

Initial situation:

The optimised and targeted use of resources is mandatory today and a key objective of modern production planning. However, existing production planning systems lack the flexibility to deal with unpredictable events that frequently occur in real industry.

Project targets:

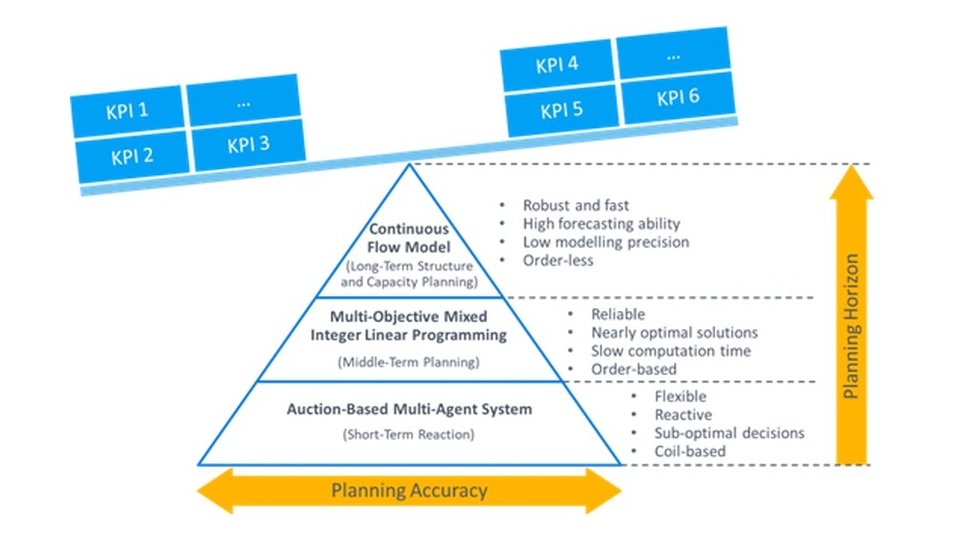

The project will realise an open-source platform for dynamic production planning that includes the full use of all available information from each participating plant to generate resource-optimised production plans for products of the highest achievable quality. The platform is based on a hierarchical planning system that combines three different planning horizons to allow dynamic reactions to unforeseen events (short-term planning), while still taking into account optimised medium and long-term planning strategies.

To improve planning accuracy, three additional components are implemented:

- A recommender system that makes recommendations in sub-optimal planning situations.

- A coil order allocation system that enables an optimised allocation of raw material to orders.

- A system for modelling plant performance that provides real-time estimates of plant performance in relation to various aspects such as resource consumption or product quality.

Innovative approaches:

- Combination of global routing and local planning at plant level to utilise synergies and improve planning objectivity by reducing random operator decisions.

- Consideration of the characteristics and specific features of each coil to achieve a dynamic production flow.

- Dynamic reaction strategies for unplanned events such as system failures and material failures in an intermediate production step to avoid additional costs.

- Consideration of all available information and real-time plant performance indices to calculate the optimal route for each coil.

Benefits for the industry:

DynReAct_PDP offers a novel way of multi-criteria optimised and coil-oriented scheduling with an integrated knowledge-based approach to extract all necessary patterns relevant to performance targets.

Another potential industrial impact can be increased productivity and yield through more homogeneous production schedules, minimisation of set-up times and reduced use of dummy and set-up coils. Such an increase in productivity and yield will increase resource efficiency and competitiveness and will lead to more sustainable production.

In addition, improved yield will lead to a reduction in energy consumption, waste and CO2 emissions. The improved delivery performance will lead to higher customer satisfaction, which will improve the image of steel producers.

Below you will find further information on the project: https: DynReAct

Please follow us on linkedin for the latest information about the project!

partners

Funding reference

Your contact person

47 Dr. Christoph Nölle

+49 211 98492-653

christoph.noelle_at_bfi.de