Electroless nickel dispersion coating for wear protection

Situation:

Tool wear occurs during cutting and forming

- Temperature gradients and deviations.

- Mechanical stresses.

- Abrasion and surface fatigue.

Solution:

- Development of wear protection systems based on chemical nickel dispersion coatings.

Operational benefit:

- Reduction of wear.

- Increase in service life.

- Reduction of the downtimes for tool change.

- Reduction of the maintenance time and costs of the tools.

The projects funded by the European Union and the state of North Rhine-Westphalia investigate the following topics:

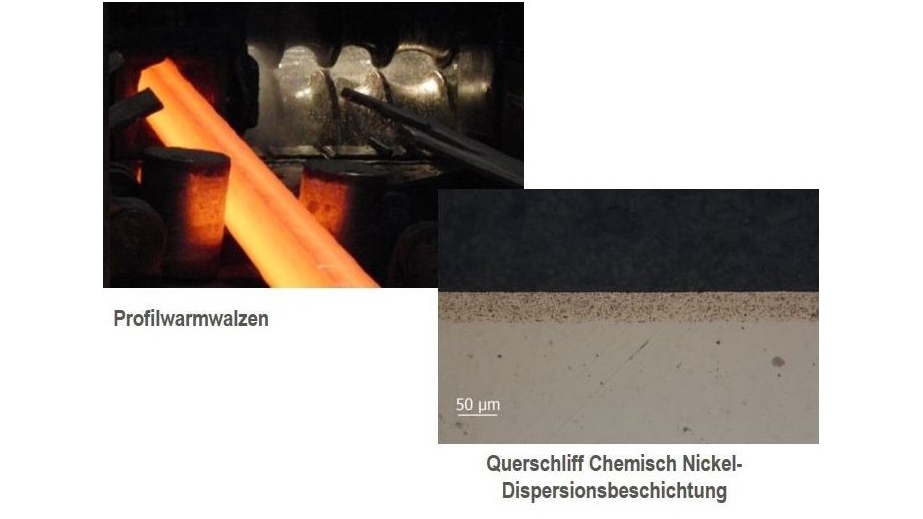

- DisperTherm: wear protective coatings for rolls in long product hot rolling process.

- non-stick-FiReNi: the electroless nickel dispersion layers are currently being optimised for use on highly loaded cutting tools.

Download:

Your contact person

14 Dr. Jessica Schindhelm

+49 211 98492-683

jessica.schindhelm_at_bfi.de