EnerMIND - Energy Management in the Era of Industry 4.0

Initial situation:

Various successfully finished European research projects have remarkably proven the potential of intelligent through process information usage. Only in the field of Energy Management at least 5 projects can be found having important results with significant impact able to improve any state-of-the-art Energy Management System (EMS) on the market.

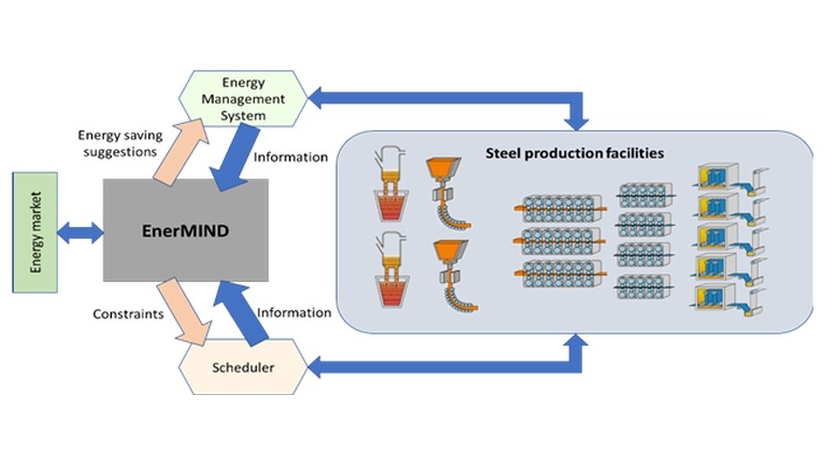

To fill this gap between research and industrial practice during EnerMIND-project one software supplier and two research institutes cooperate and realize a next generation EMS pilot solution providing energy-driven monitoring and control of the complete steel production chain exploiting latest machine learning, advanced forecasting, Industry 4.0/IOT paradigm and secure communication technologies.

Project targets:

- To demonstrate the superior capabilities obtained by data-driven and extensive Artificial Intelligence- (AI) and Machine Learning (ML)-based approaches in terms of increased precision of the forecasting of energy consumption with respect instead to the first-order modelling techniques and traditional statistical approach.

- To demonstrate the increased flexibility because of the compliancy with the Industry4.0 paradigm through the implementation of the Industrial Internet of Things (IIoT) principles to realize a new generation of Energy Management System (EMS) fully integrated with the production management aimed at optimizing the Energy consumption and reducing the related environmental impact.

- To optimize the approach to the electric energy market in relationship with the production planning and scheduling by means of innovative optimization AI-based algorithms.

- To analyze online anomalies in the energy consumption through the continuous monitoring of energy flow in real time conditions.

- To make available the guidelines for designing energy digital twins in the industrial environment empowered by Machine Learning techniques as a decision support system and a training environment at the same time.

Innovative approaches:

The innovative content of the project is based mainly on three aspects:

- the IIoT distributed architecture of the solution,

- the dramatic enhancement of the state-of-the-art capabilities to be fully integrated into the new architecture, including the realization of an energy-oriented digital twin of the plant,

- The direct connection to the electric energy market.

This will allow to efficiently add the other capabilities like scenario analysis, improving flexibility, enhancing forecasting precision and reducing processing time. The updated HMI will provide a new ergonomic way to include operators in the loop.

All such expectations are ensured by the integration of data sources (meters and smart meters, sensors etc.) for the energy continuous monitoring mission allows implementation of data-driven and AI-based models to empower the precision and flexibility of prediction and enhanced robustness with respect to anomalies.

Moreover, the enhanced forecasting is finalized to empower also retroactive reactions thanks to the increased precision and robustness to make a step ahead in this aspect.

The new concepts to go further making available and validating a framework / platform for detecting multiple energy vectors, some of them exploited in the project like electric energy and gas and in the future others like water, air, argon, etc. where it is relevant.

Benefits for the industry:

- Expected benefits are superior capabilities like forecasting, multi-objective optimization for energy supply and scheduling improvement, product quality and event management.

- Deployment of the Industry4.0 technologies, namely IIoT, Artificial Intelligence and Machine Learning (AI / ML) were done for investigating the new possibility opened by this kind of architecture like the combination with the Cloud Computing network.

- Benefits to extensively adopt the data-driven approach and the approach were reached in comparison with currently available first order models and optimization techniques.

- Depending on the level of digitalization of the plants and the skills of the workforce, the global expected benefits are to decrease the energy consumption due to the reduced mix of steel families and product typology in the reheating furnace charge.

- The solution and the predictive optimization of the consumption of the main production lines has the potential consequence to optimize other consumption issues like water and compressed air in the auxiliaries in combination with the rolling mill.

partners

Funding reference

Your contact person

53 Dipl.-Ing. Achille Fabien Nkwitchoua Djangang

+49 211 984-92-251

Fabien.Nkwitchoua_at_BFI.de