FeEnCap - Encapsulated iron materials for new type of iron slurry/air batteries

Initial situation:

- The increasing expansion of wind and solar power is leading to strong fluctuations in the amount of energy fed into the electricity grids.

- Pumped storage power plants are only available regionally as electrical energy storage facilities to stabilise the grids.

- Lithium-ion or vanadium redox storage systems are comparatively expensive for stationary energy storage and/or use toxic battery materials.

Project targets:

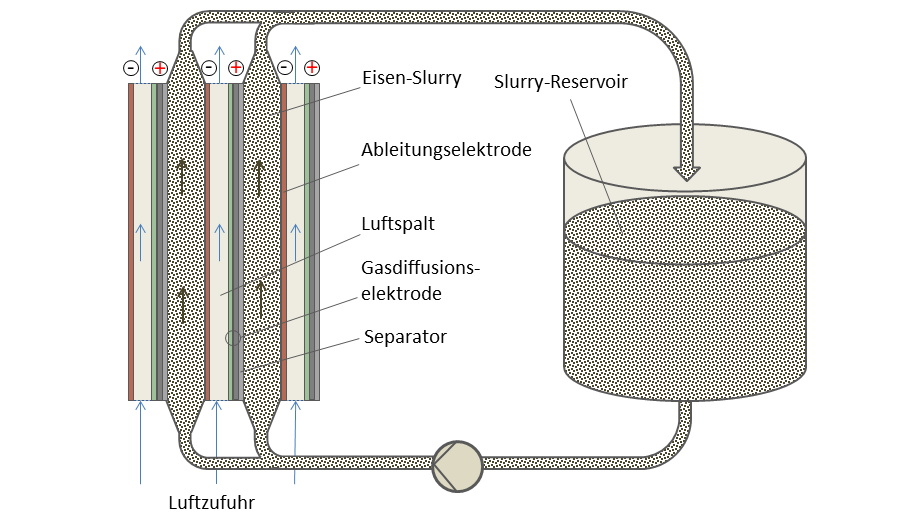

- Research into a new type of low-cost iron slurry/air storage system in which an iron-containing battery mass can be pumped through the battery cell in the form of a slurry during operation and stored in a reservoir outside the cell

- Improving the rechargeability of the battery by using slurry particles with a special core/shell design

- Further development of electrolytic flow-through cells for iron slurry/air batteries

Innovative approaches:

- Innovative use of iron in metal slurry/air batteries

- Reduction of the contact resistance between the particles and avoidance of disruptiv iron deposits on the contact electrodes by using special iron-based composites and particles with a core/shell design

Benefits for the industry:

- Scalability of the system, especially for high-capacity electrical energy storage

- Use of environmental-friendly, low-cost and readily available battery materials for the production of electrical energy storage systems

- Simple recycling of the battery mass

- Starting materials and slurries can be produced on an industrial scale

partners

Funding reference

03XP0536F, funded by the BMBF

Your contact person

36 Dr. Andreas Bán

+49 211/98492-314

andreas.ban_at_bfi.de