FlexGap – Industrial demonstration of novel adaptive flat bearing

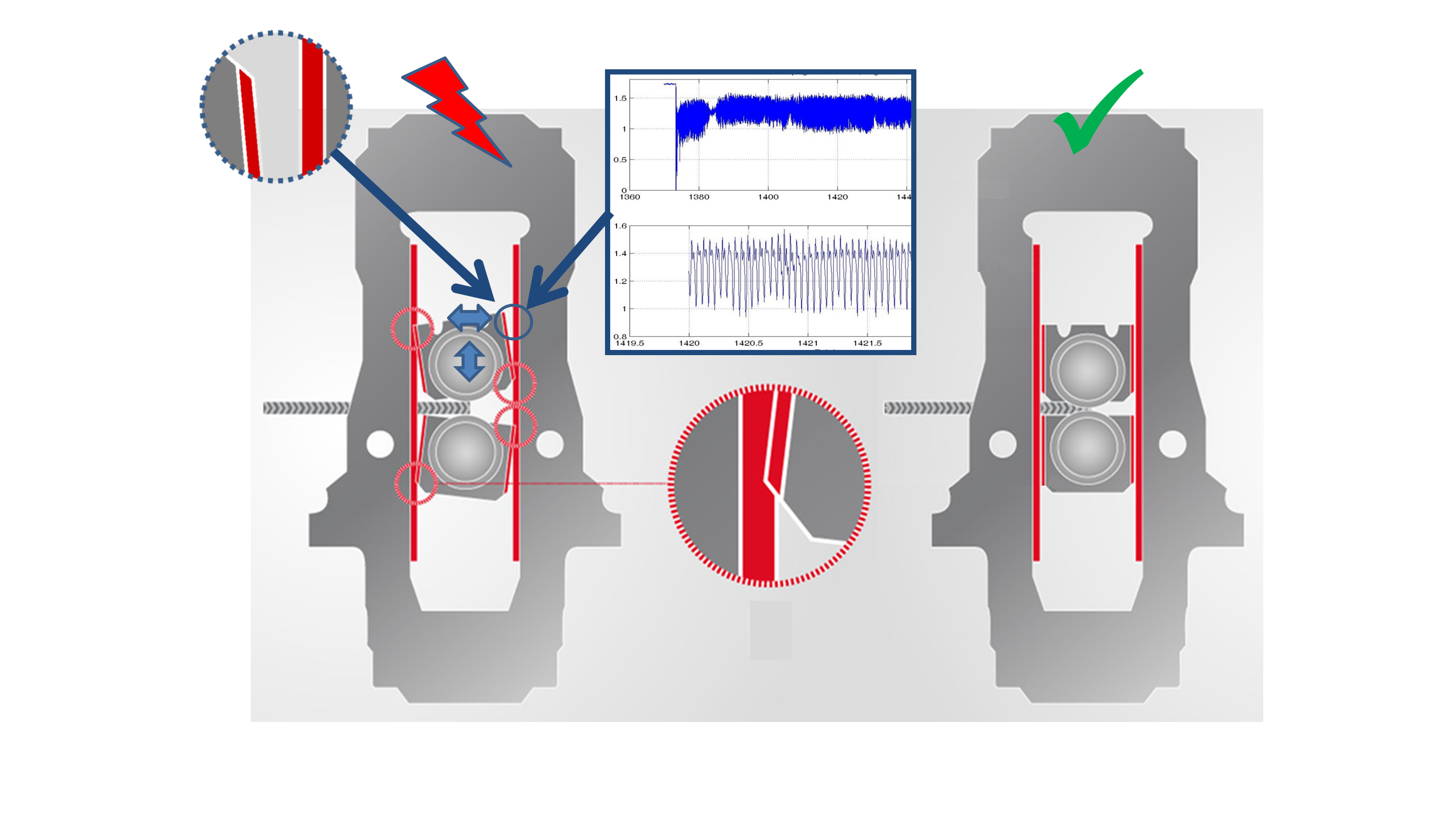

With more and more need for high-strength-steel the rolling-mills have to be expanded to deal with the resulting higher rolling-forces. An effect of this is the greater constriction of the rolling-stand. Therefore the flat-bearings, guiding the chocks, have to be designed thinner to avoid clamping. On the other hand, while rolling lower-strength-steel, these thinner flat-bearings cause worse guidance of the rolls, higher wear and greater oscillation tendency that allows self-excited vibrations to build up a high magnitude. This effect is known as chattering and can cause strip-breakage. A common reaction to this is to lower the speed of the rolling-mill which results in a reduced productivity of the plant.

In response to this trend a new adaptive flat-bearing was developed. The expected benefits of the new adaptive flat-bearing are on-line adaptation of a minimal bearing-gap, on-line adjustment of the roll-offset, dumping of self-excited vibrations and a possible use as an additional flatness-actuator.

Aims of the project:

- Better process-guiding for all Strengths.

- Minor oscillation tendency.

- Dumping of chattering vibrations without the need of speed reduction.

- Minor wear due to more parallel planes inside the bearing-gap.

Steps to carry out the project:

- Initial setup.

- Development of needed controls.

- Test of expected benefits.

Benefits for the industrial partner:

- Higher productivity due to the avoiding of speed-reduction.

- Lower maintenance costs.

partners

Funding reference

Your contact person

42 Moritz Loos, M.Sc.

+49 211 98492-242

moritz.loos_at_bfi.de