FluoridSelektiv - Process development for selective fluoride separation from industrial process water

Initial situation:

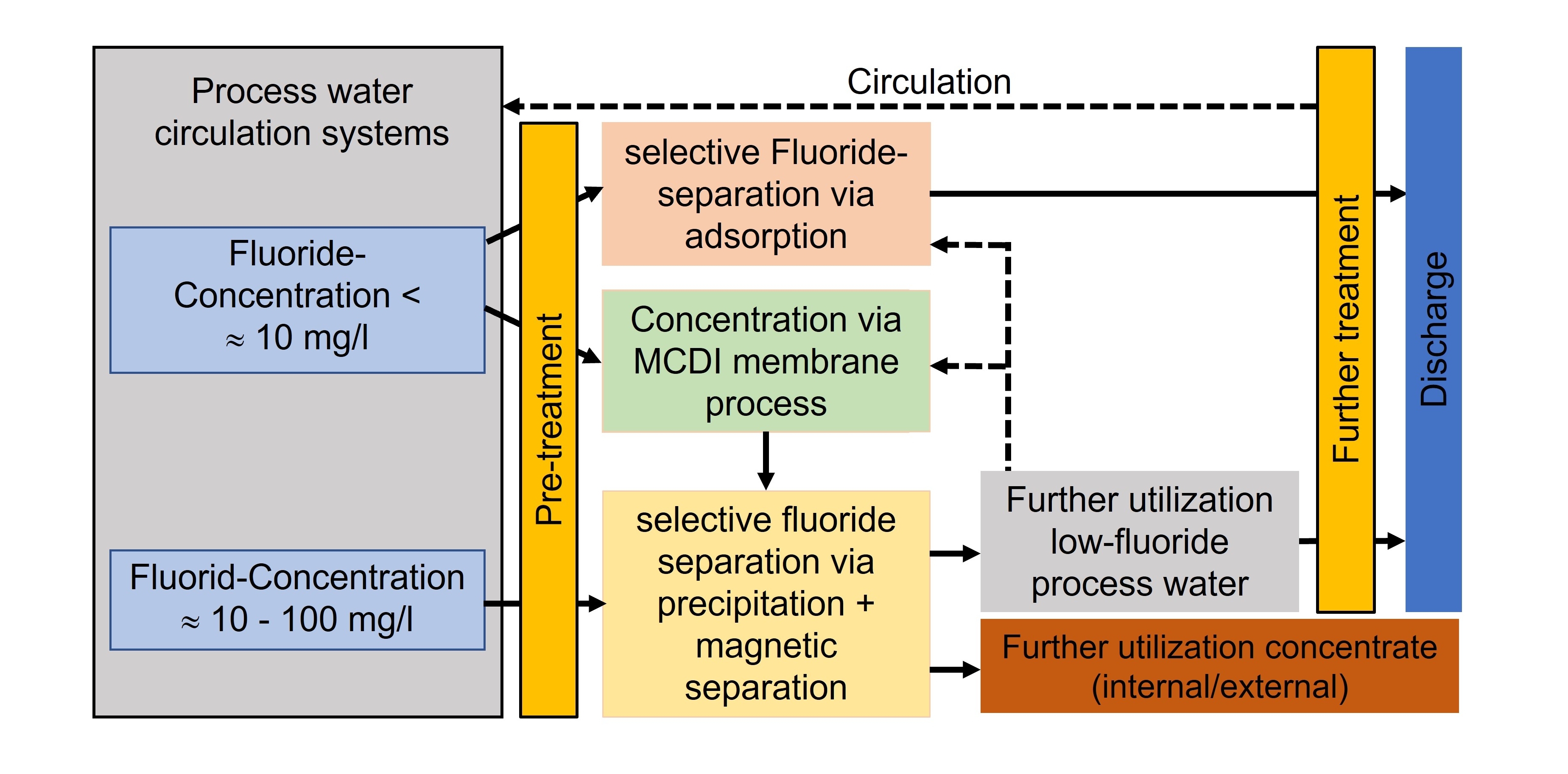

Process water from pig iron and steel production has fluoride contents of up to 100 mg/L. A selective separation of the fluoride is necessary and useful for derivation or circulation. If fluoride remains in the concentrate during process water desalination, it is often not usable and cannot be disposed of. The methods of selective adsorption and selective precipitation are suitable for effective fluoride separation.

Project targets:

- Development of selective fluoride separation from process water used in pig iron and steel production, differentiated according to fluoride contents of less than and greater than approx. 10 mg/L by means of adsorption and precipitation

- Reduction of disposal costs for concentrates by producing a usable fluoride concentrate

Innovative approaches:

- Adsorption

- Application of the process for concentrations below 10 mg fluoride/L

- Use of fluoride-selective adsorbers

- Selective precipitation with combined separation

- Application of the process for concentrations greater than 10 mg/L

- Concentration of process water less than 10 mg fluoride/L using MCDI (membrane-based capacitive deionisation)

- Use of a calcium-based by-product from the steel industry for precipitation

- Binding of the precipitated calcium fluoride to a magnetisable particle for efficient separation via a magnetic separator

- Purification and production of a usable fluoride concentrate

- Regeneration of the magnetic carrier particles

Benefits for the industry:

- Sustainability potential

- Avoidance of ‘mixed concentrates’ that have to be landfilled

- Use of calcium-based by-products from steel production and processing for fluoride precipitation

Benefits for the user:

- Improved circulation of process water through efficient and selective fluoride separation

Please feel free to contact us

- if you are the operator of a continuous casting plant

- if you want to selectively separate fluoride concentrations in the gas scrubbing water of the blast furnace

- if process water is to be desalinated and mixed concentrates are produced

Funding reference

FKZ 01IF23436N

Your contact person

23 Dr.-Ing. Matthias Werner

+49 211 98492-539

matthias.werner_at_bfi.de