FOMTM – Application of fibre optical thermal monitoring at CC-billet and slab mould for improved process control and product quality

Initial situation:

- The initial solidification of the molten steel is important for determining the quality of the cast product

- Rim formation can have severe damaging impact on the surface of the solidifying strand

- Currently no regular use of thermal mould monitoring for tube moulds for long product casting

Project targets:

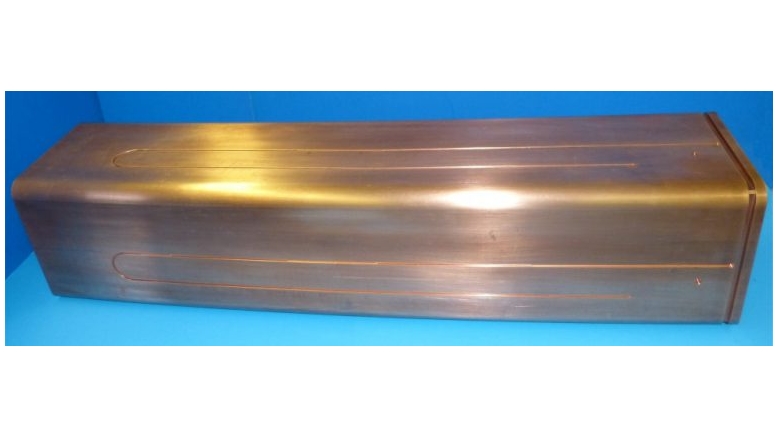

- Design of an fibre optic temperature sensor (FOTS)

- Realisation and installation of pilot FOTS system

- Industrial trials on the caster with pilot FOTS system and the developed analysing software

- Data elaboration and rules, tuning of the system, industrial transferability, suggestion for standards

Innovative approaches:

- Develop and operate a better control of initial solidification at meniscus level

- Further develop fibre optical mould temperature sensors for multiple use

- Operate the system under industrial practise at a billet and slab mould

Benefits for the industry:

- Enhance surface quality of as-cast products

partner

Funding reference

RFSP-CT-2012-00007

Your contact person

49 Dr. Marc Köster

+49 211 98492-894

Marc.Koester_at_bfi.de