GeoCRM - Geometallurgical processing of steelmaking slag for recycling critical raw materials and CO2 binding

Initial situation:

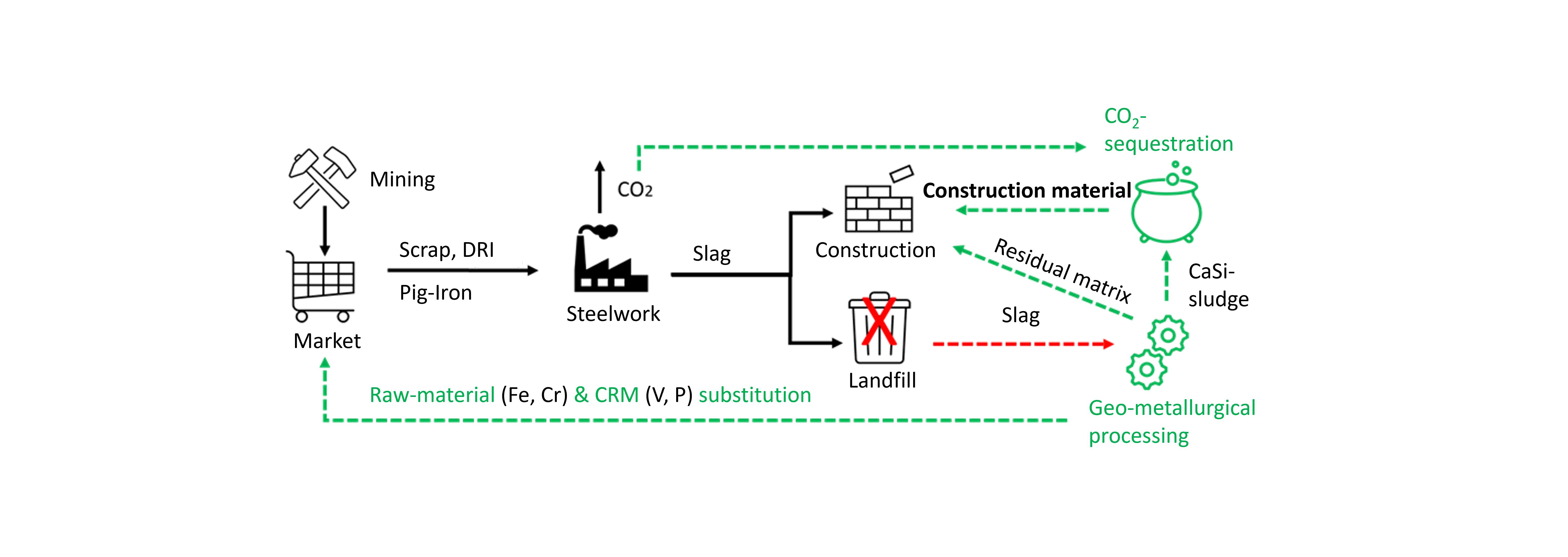

With an annual crude steel production of 37 Mt/a (2022), which corresponds to approximately 27% of European production, German steel manufacturing is an essential economic and material sector. Critical raw materials (CRM), such as vanadium and phosphorus, are contained both in the raw materials used (e.g. ores) and in slag, the largest by-product in terms of quantity. Slags fulfil important metallurgical tasks in the process, such as absorbing unwanted chemical compounds. Their composition is specifically adjusted for this purpose. From an ecological, economic and circular economy perspective, CRMs should be recovered from slag in the future. Particular attention is being paid to the development of key technologies for recycling the slag matrix and/or upgrading materials for other branches of production, such as aggregates in cement production.

Project targets:

The aim of the project is to develop a processing concept for the holistic recycling of steelworks slag. Based on a geometallurgical analysis, the concept allows the process route that enables the optimal recovery of iron oxide and critical raw materials such as phosphorus, vanadium and chromium to be determined. In addition, the remaining calcium silicate fraction is to be processed in a manner that it can be used for the permanent binding of CO2 and, at the same time, as a raw material for building materials.

Innovative approaches:

To this end, the raw materials, intermediate products and final concentrate and tailings fractions are examined using quantitative mineralogical methods. In addition to classic analyses of the chemical and mineralogical composition, this also includes investigations into the textural properties of the materials. Such parameters can be determined semi-automatically using microanalytical automated methods such as QEMSCAN, MLA or µXRF. This allows critical parameters for processing to be derived, such as the identification of valuable and waste mineral fractions, the distribution of valuable elements and the particle size of the individual mineral phases containing valuable elements. This information is used in the context of processing and metallurgy to establish a geometallurgical particle model. Based on this, processes can be specifically adapted to the material flows at hand and thus optimised.

Benefits for the industry:

The geometallurgical model of steelmaking slag based on the analysis of the slag allows us to predict which recycling route will enable the most optimal use of the slag. This can significantly reduce the landfill rate for slag and replace raw materials with recycled products.

Funded by:

Project Management:

partners

Funding reference

Your contact person

34 Simon Wölfelschneider, M.Sc.

+49 211 98492-221

simon.woelfelschneider_at_bfi.de