H2loop - Sustainable decarbonisation of integrated steel plants by hydrogen production from chemical looping

Initial situation:

- The European steel industry faces the challenge of reducing its CO₂ emissions by 55% by 2030 and becoming climate neutral by 2050 without losing its competitiveness.

- All major European steel producers have published transformation roadmaps to meet the targets of the EU climate plan.

- The transition from the traditional blast furnace-converter route to more climate-friendly production processes requires gradual action and long-term planning.

- The growing importance of hydrogen as a future reducing agent places new demands on availability, infrastructure and economic efficiency.

- A major obstacle to decarbonisation could be the insufficient supply of low-cost, green hydrogen.

- In parallel with the transformation, steelworks must secure their economic performance while achieving CO₂ targets.

Project targets:

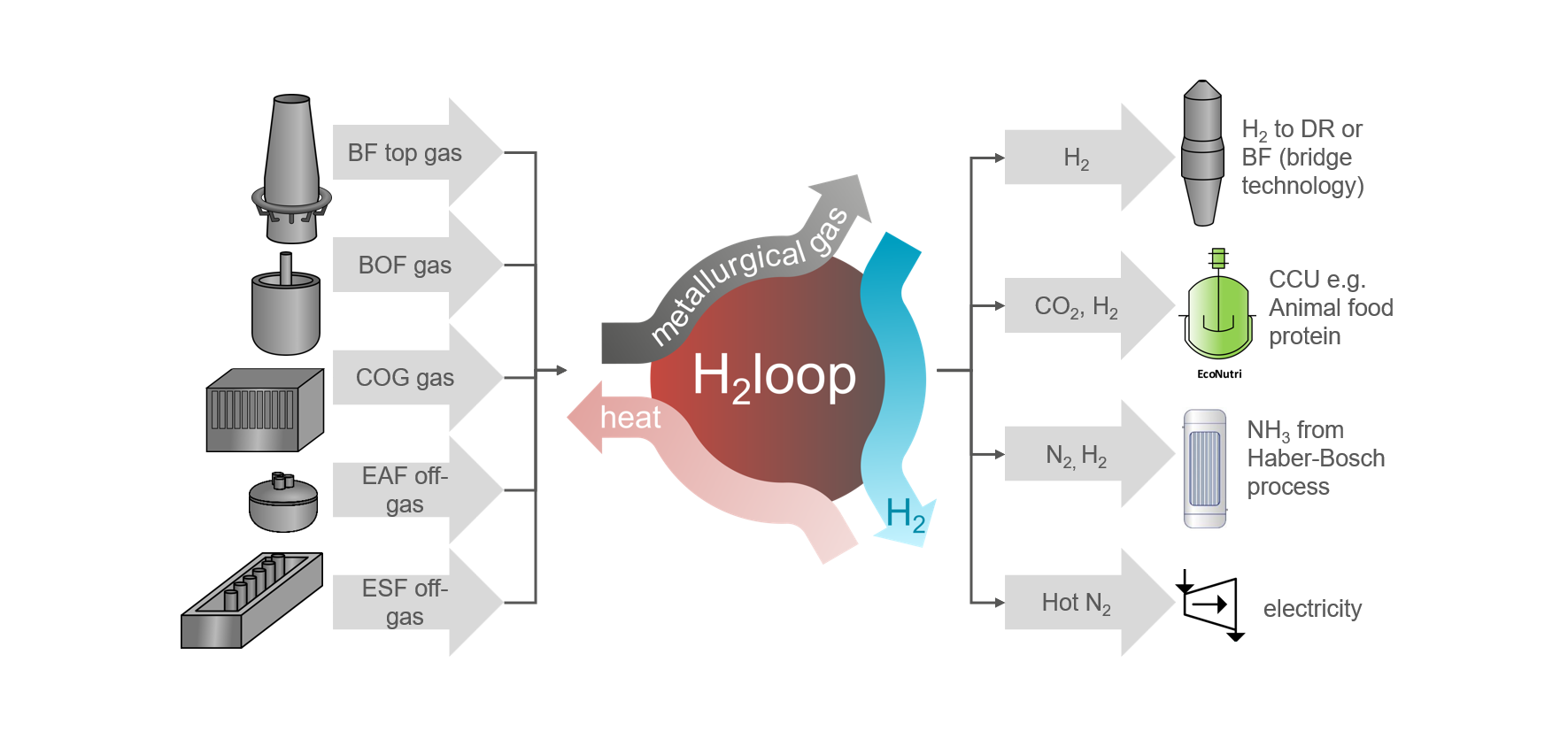

- Development and demonstration of an innovative chemical looping process (CLH) for efficient, emission-free and cost-effective hydrogen production from metallurgical gas streams in the steel industry.

- Utilisation and upgrading of existing process gases (e.g. blast furnace gas, converter gas) for the production of high-purity hydrogen (>99%) and valuable by-products such as CO₂/N₂-rich gases and usable process heat.

- Demonstration of the CLH process on an industrial scale with 24/7 operation, real-time control and AI-supported soft sensors for optimising efficiency and process monitoring.

- Modular oxygen carrier materials with high reactivity and long-term stability (> 10 years) for large-scale industrial use.

- Integrated concept of current and future steel mill structures (BF-BOF, DR-EAF) with fully integrated CLH process.

- Energy and economic analyses, including life cycle assessment (LCA), to evaluate resource efficiency and environmental benefits.

- Scale-up concept and business plan for the industrial implementation of the CLH process in the European steel industry.

Innovative approaches:

- Use of the chemical looping process (CLH) for highly efficient, emission-free hydrogen production from metallurgical process gases (e.g. from blast furnaces).

- Three-stage reaction process for reduction, hydrogen production and heat recovery, based on iron oxide as an oxygen carrier with high reactivity and stability.

- Integration of the CLH process into existing and future steelworks routes (BF-BOF, DR-EAF) to provide hydrogen, heat and CO₂-/N₂ streams for CCU/S applications.

- Prevention of carbon deposits through optimised temperature control and optional steam injection.

Benefits for the industry:

- Significant reduction in carbon footprint through the use and upgrading of metallurgical process gases to high-purity hydrogen, heat and CO₂/N₂ streams for CCU/S applications.

- Increased energy efficiency through chemical looping with an internal heat recovery system, significantly reducing external energy requirements.

- Increased resource efficiency through complete utilisation of the energy and material streams contained and avoidance of emissions from gas combustion.

- Flexible integration into existing and future production routes (BF-BOF, DR-EA) for the gradual decarbonisation of steel production.

- Creating new value-added potential by utilising by-products (e.g. CO₂ for chemical synthesis, waste heat for power generation) for maximum energy and resource efficiency.

- Ensuring a location-independent, resilient and economical hydrogen supply, thereby reducing dependence on external energy sources.

- Strengthening the competitiveness through emission-free, cost-efficient and digitally monitored on-site hydrogen production.

Further information:

Website: https://h2loop.eu/

LinkedIn: https://www.linkedin.com/company/h2loop-project/

partners

Funding reference

RFCS, project number: 101193354

Your contact person

25 Dr. Hauke Bartusch

+49 211 98492-282

hauke.bartusch_at_bfi.de