HyBeSt – Hybrid Heating in the steel industry

Initial situation

- Optimal use of renewable energy in industry poses major challenges to production flexibility.

- Synchronizing fluctuating energy supply and continuous production processes and quality requirements requires new approaches.

- Flexible use of electrical energy at thermoprocessing plants is increasingly in demand.

Project goals

- Development of a flexible, hybrid (fuel gas/electricity, preferably from renewable sources) heating solution for thermoprocessing plants.

Innovative approaches

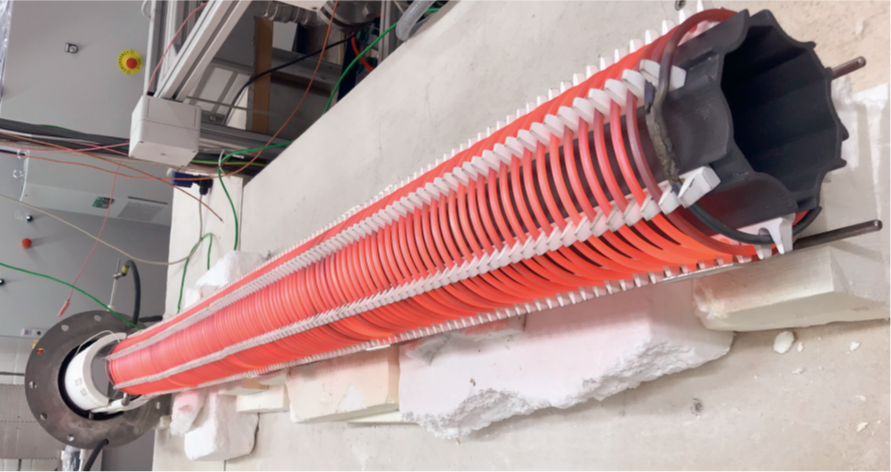

- First-time combination of fuel gas heating with electrical resistance heating in a hybrid radiant heating tube.

- Flexible use of the above energy sources in a heat treatment furnace in the steel industry.

- Use of the existing outer geometry of the radiant heating tube.

- Burner technology is simultaneously prepared for future operation with hydrogen or green fuel gas.

Possible benefits for the industry

- Energy-flexible heating of the thermoprocessing plant enables the use of different energy sources, depending on the cost situation, availability or grid efficiency.

- Marketing of energy flexibility as well as avoidance of CO2 emissions.

- Easy replacement of existing technology due to identical dimensions of the new system.

Funding source: German Federal Ministry of Education and Research (The joint project is a research project within the funded Kopernikus project SynErgie – Synchronized and energy-adaptive production technology for flexible alignment to a fluctuating energy supply)

Duration: 01.11.2019 – 30.06.2023

Funding reference

Förderkennzeichen: 03SFK3P0-2

Your contact person

18 Dr.-Ing. Andreas Queck

+49 211 98492-290

Andreas.Queck_at_bfi.de