Infire – Strategy to increase the hot strip rolling performance in terms of surface quality, final properties and reproducibility

Situation:

- Achieving high surface quality of hot rolled high strength steel strip and reproducible rolling results remains challenging:

- Primary scale residues and scale formed during rolling lead to surface impairments.

- Influences and interrelations of process conditions on product quality are poorly known.

- As steel grades with higher strength are demanded, hot rolling conditions change.

Solution:

- Adopting primary scale residues and finished strip monitoring systems for prognosis of scale defects.

- Investigation on sensitivity of the rolling result on process parameter.

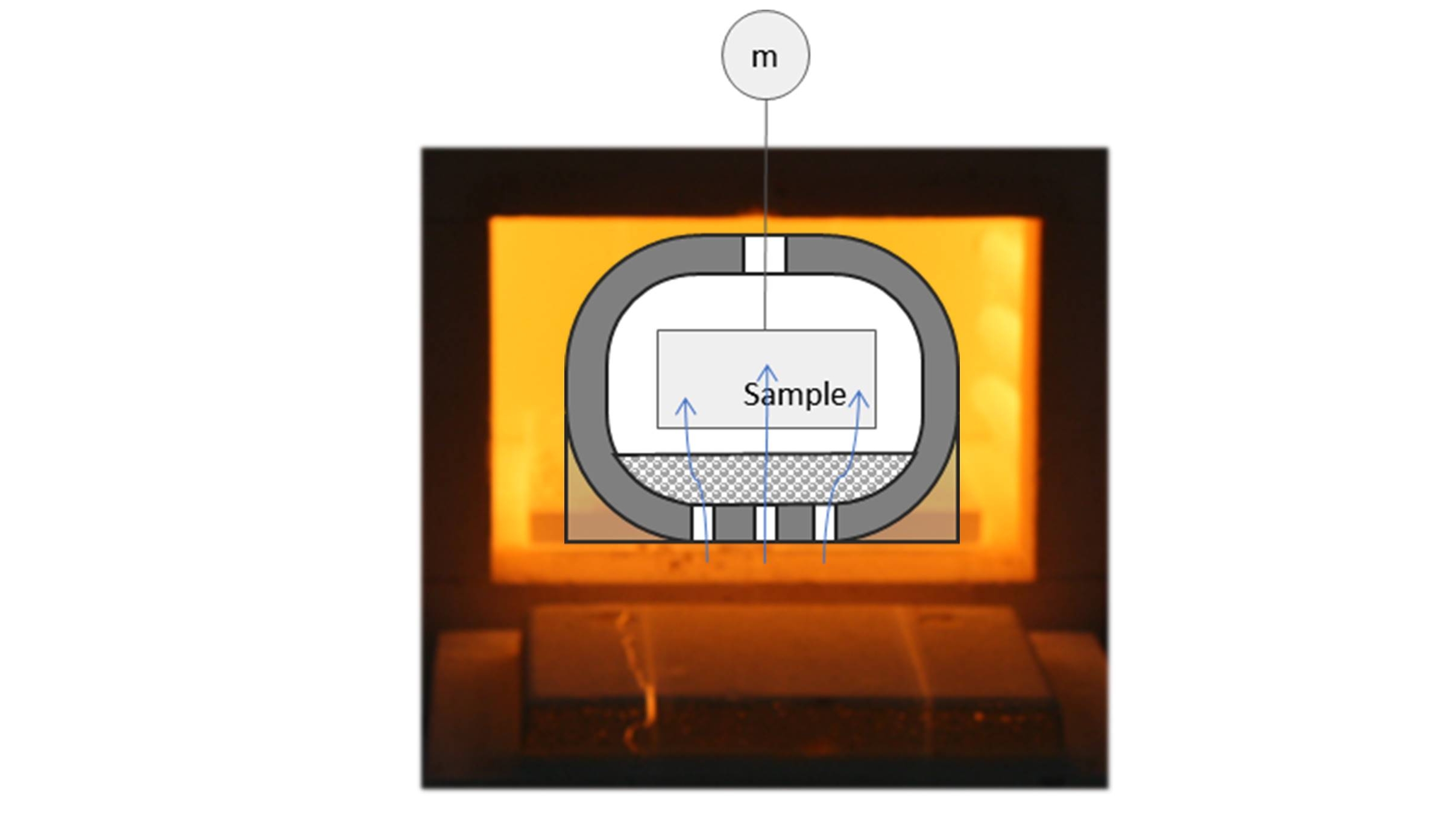

- Novel methods to control scale growth and fracture behaviour with the optimisation of rolling parameters as well as rolling actuators and application of oxide modifiers.

- Create a model to predict scale behaviour.

Operational benefit:

- Minimisation of effects of scale on the final surface texture and strip mechanical properties.

- Improvement of the surface quality of critical high alloyed steel grades by understanding and conditioning scale formation during rolling and cooling.

- Definition of the optimum rolling and cooling conditions for industrial application towards a significant improvement of the quality of the final product for high value added steels.

- Enabling existing plants to handle new kind of high strength steel grades in a more efficient and reproducible way.

partners

Funding reference

RFCS

Your contact person

6 Martin Wunde, M.Sc.

+49 211 98492-316

martin.wunde_at_bfi.de