InnoKon – Innovative non-stick surface to increase the service life of oxygen lances on the converter

Initial situation:

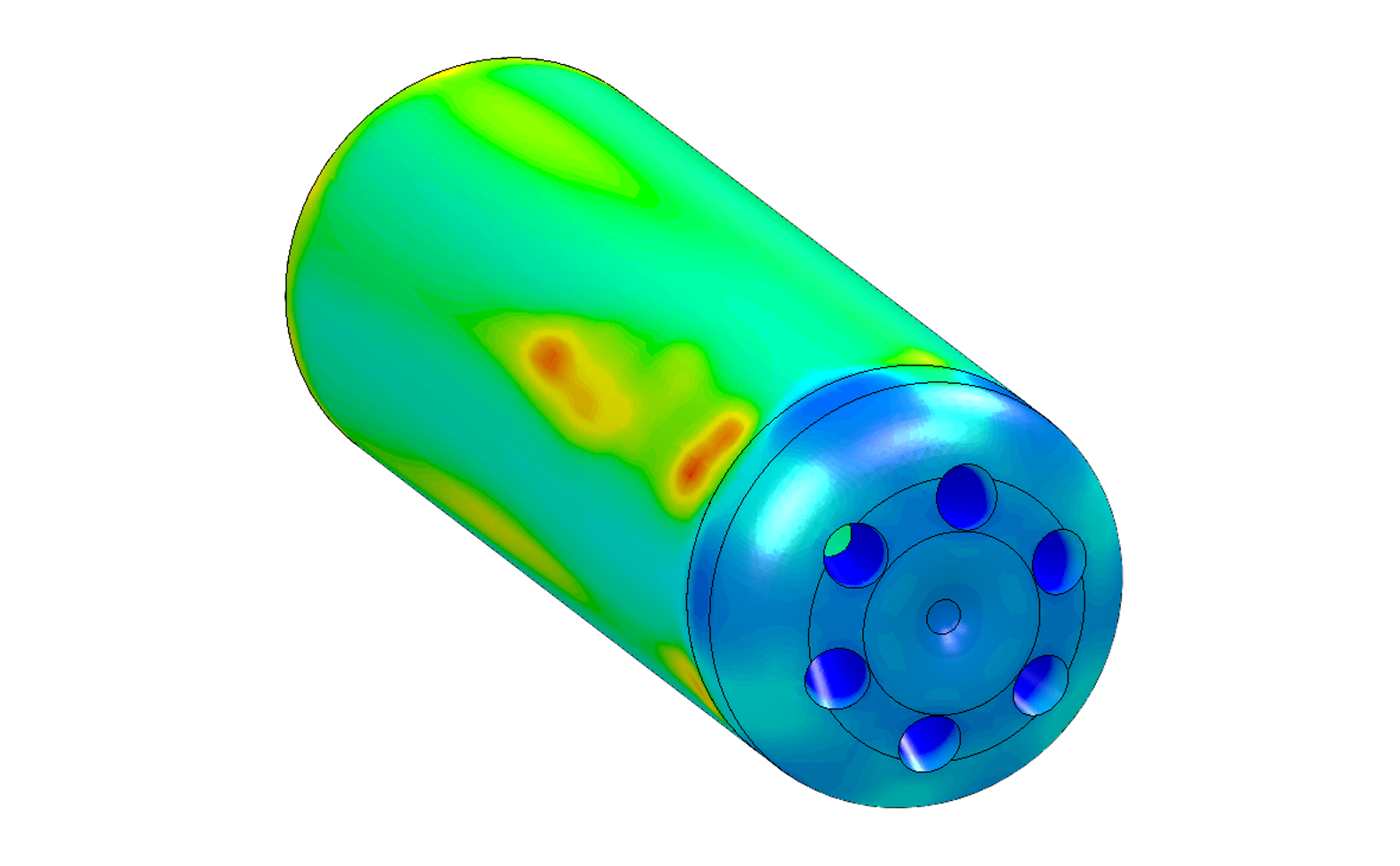

- In the converter process, oxygen is supplied via a high-pressure lance.

- This high-pressure and high-temperature process causes turbulence in the melt, causing drops of iron, slag, and steel to hit the lances and adhere to them.

- These deposits (called “bears”) are burned off over time - and with considerable energy expenditure - to keep the lance operational

Project targets:

- Development of a specially conditioned surface that allows iron, slag, and steel droplets to roll off, thereby increasing the operating time of the lances

Innovative approaches:

- Development and operational testing of a high-temperature-resistant coating in a technologically challenging process environment

Benefits for the industry:

- Increased service life of converter lances

- Reduced energy and time required for burning off lance bearings

- Economic advantages due to lower maintenance costs

Funding source: Federal Ministry for Economic Affairs and Climate Action

Duration: 01.10.2020 – 30.09.2024

partners

Funding reference

03EN2055A-D

Your contact person

18 Dr.-Ing. Andreas Queck

+49 211 98492-290

Andreas.Queck_at_bfi.de