MaxH2DR - Enrichment of Hydrogen in the direct reduction process

Hydrogen-powered direct reduction (DR) is the key technology for decarbonizing integrated steel plants. Natural gas-fired DR is well established in the industry, especially outside Europe. There is no experience with high H2 enrichment above 80%.

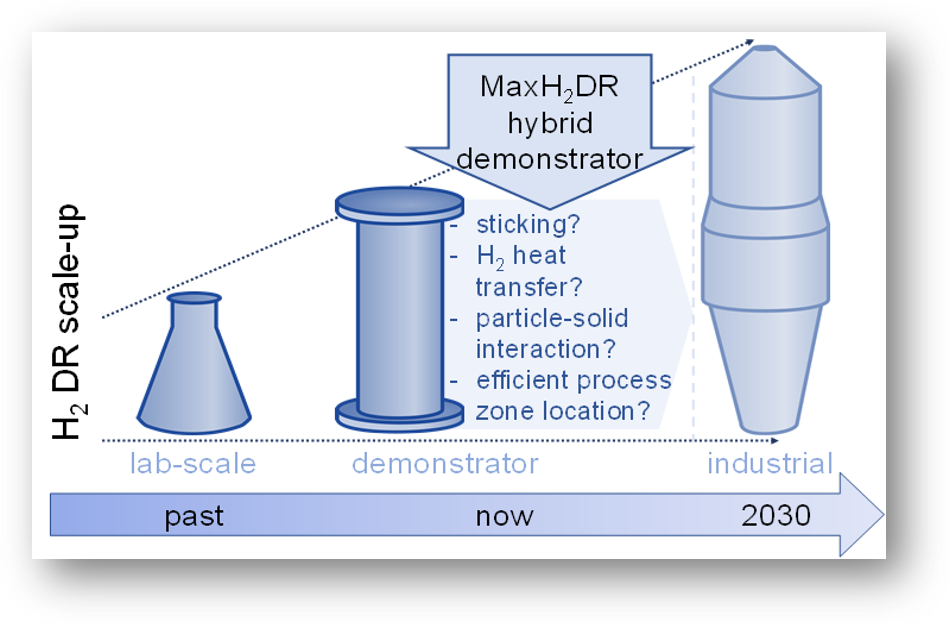

H2-based reduction is not a fundamental problem, but the overall processes are endothermic and the influences on morphology and effective kinetics are unknown. The properties and movement of the particles in the reactor are also unknown, and problems such as sticking cannot be ruled out. The temperature distribution and flows are likely to differ significantly from current processes. Reliable predictions are not yet possible, especially regarding local permeability, process stability, and product quality of industrial-size furnaces.

MaxH2DR provides missing knowledge and data on reduction processes. The determination of pellet properties under process conditions and the interaction of solid and gas flow in a physical demonstrator provides data for digital models, such as the key technology DEM-CFD. On this basis, the integration of the process into existing process chains is optimized. The simulation tools are combined into a toolkit that analyzes the effects of product properties on downstream processes as well as the effects on gas and energy consumption.

MaxH2DR is honoured with the Net-Zero Industries Award 2024!

partners

Funding reference

Your contact person

50 Thomas Piontek

+49 211 98492-258

Thomas.Piontek_at_bfi.de