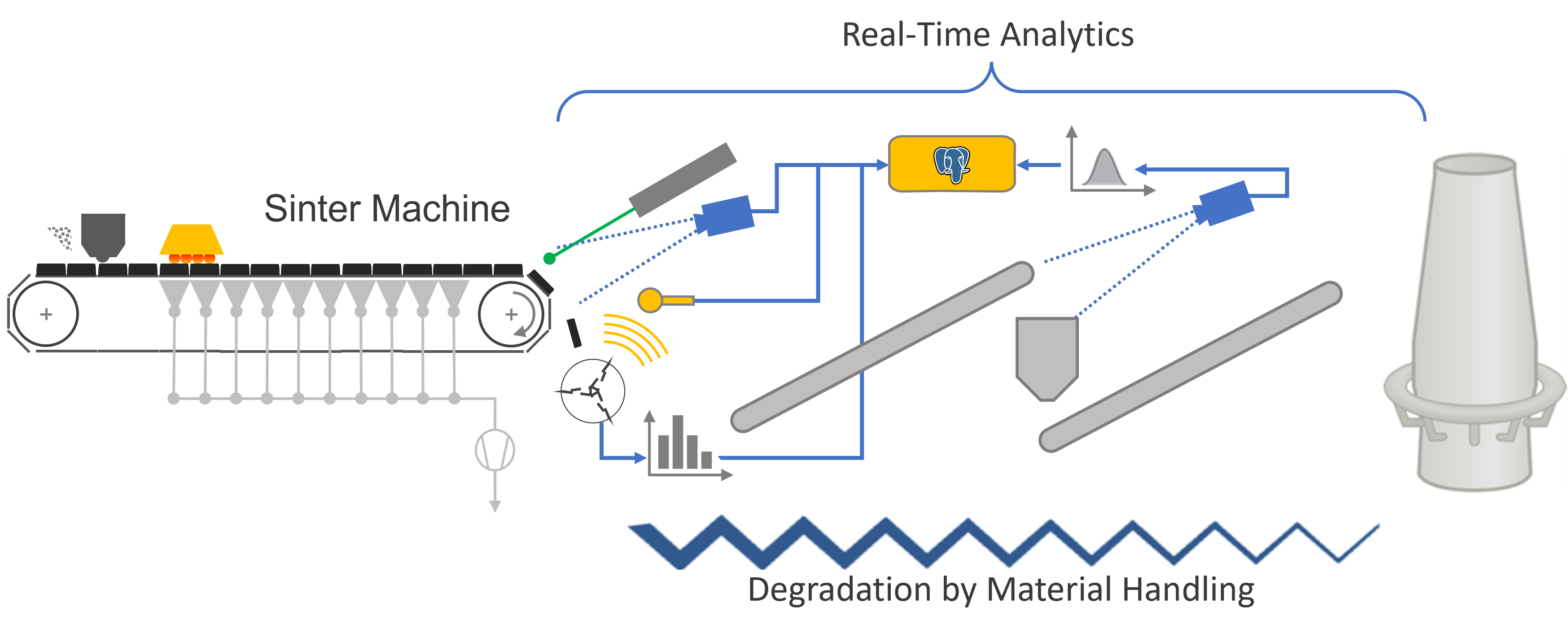

MinSiDeg - Minimisation of sinter degradation between sinter plant and blast furnace exploiting embedded real-time analytics

Initial situation:

- Fluctuation of sinter quality in time scales of minutes to several hours

- Detrimental influences of transport and storage procedures between sinter plant and blast furnace

Project targets:

- The Major objective of the project MinSiDeg from the economic and ecologic point of view is to decrease significantly costs and environmental impact at sinter plants and blast furnaces.

- From the technical point of view, major objective is to optimise the sinter quality along the production chain improving both, sinter plant and blast furnace operation.

Innovative approaches:

- Industrial real time monitoring of the physical aspects of sinter quality

- Development of new online methods for sinter quality determination

- Machine-supported decision support to optimize the sinter process in real time

Benefits for the industry:

- New knowledge on sinter breakage behaviour synthesized in innovative simulation methods

- New transport and storage technologies to decrease sinter degradation and segregation effects

- New online sinter quality measurement techniques

- Guidelines for a break-through in operational sinter quality monitoring

- Correlation of sinter quality with the blast furnace permeability

- Machine supported sinter quality control and maintenance by an embedded real-time assistance tool

Publications:

- E. Thienpont, T. Hauck, K. Walter, E. Schuster, R. Schwalbe, S. Wienströer, T. Kleinert, Application of Big Data approaches for model-based prediction of sinter quality indices,Conference proceedings, 6th ESTAD, Düsseldorf, Germany, 12th – 16th June 2023

- Thienpont, E.K., Hauck, T., Eroglu, T., Kleinert, T., Walter, K., New Measurement Techniques Describing the Sinter Process, Information Systems and Technologies, WorldCIST 2023, Lecture Notes in Networks and Systems, vol 802. Springer, 2024, pp.239-247, https://doi.org/10.1007/978-3-031-45651-0_24

- T. Hauck, K. Marx, T. Eroglu, E. Thienpont, S. Wienströer, R. Schwalbe, C. Hillmann, K. Walter, E. Schuster, C. Weichbold, M. Prenner, M. Denzel, M. Schatzl, C. Gruber, M. Thumfahrt, Minimise sinter degradation between sinter plant and blast furnace exploiting embedded real-time analytics (MinSiDeg), RFCS Grant No. 847285, Periodic Report 1&2, 2019-2023

- Denzel, Michael; Prenner, Michael, Minimierung des Sinterzerfalls mittels DEM, Berg Huettenmaenn Monatsheft,vol 166(2), pp.76-81, 2011

- Denzel, Michael Alexander, A Breakage Model for Discrete Element Simulations Applied to Iron Ore Sinter, PhD thesis, University of Leoben, 2023

- Denzel, Michael And Prenner, Michael And Sifferlinger, Nikolaus A., Development of an automated single particle impact tester for iron ore sinter, Minerals Engineering, vol 175, 2022

partners

Funding reference

Research Fund for Coal and Steel (RFCS) 2018, Nr. 847285

Your contact person

31 Dipl.-Ing. Emanuel Thienpont

+49 211 98492-387

emanuel.thienpont_at_bfi.de