NanoZunKonLub – Application of nanoparticle enhanced coatings for scale conditioning in die forging processes in order to optimize the tribological system

Situation:

- Scale formation of 1 to 2 % during reheating of the material for die forging process lead to material losses.

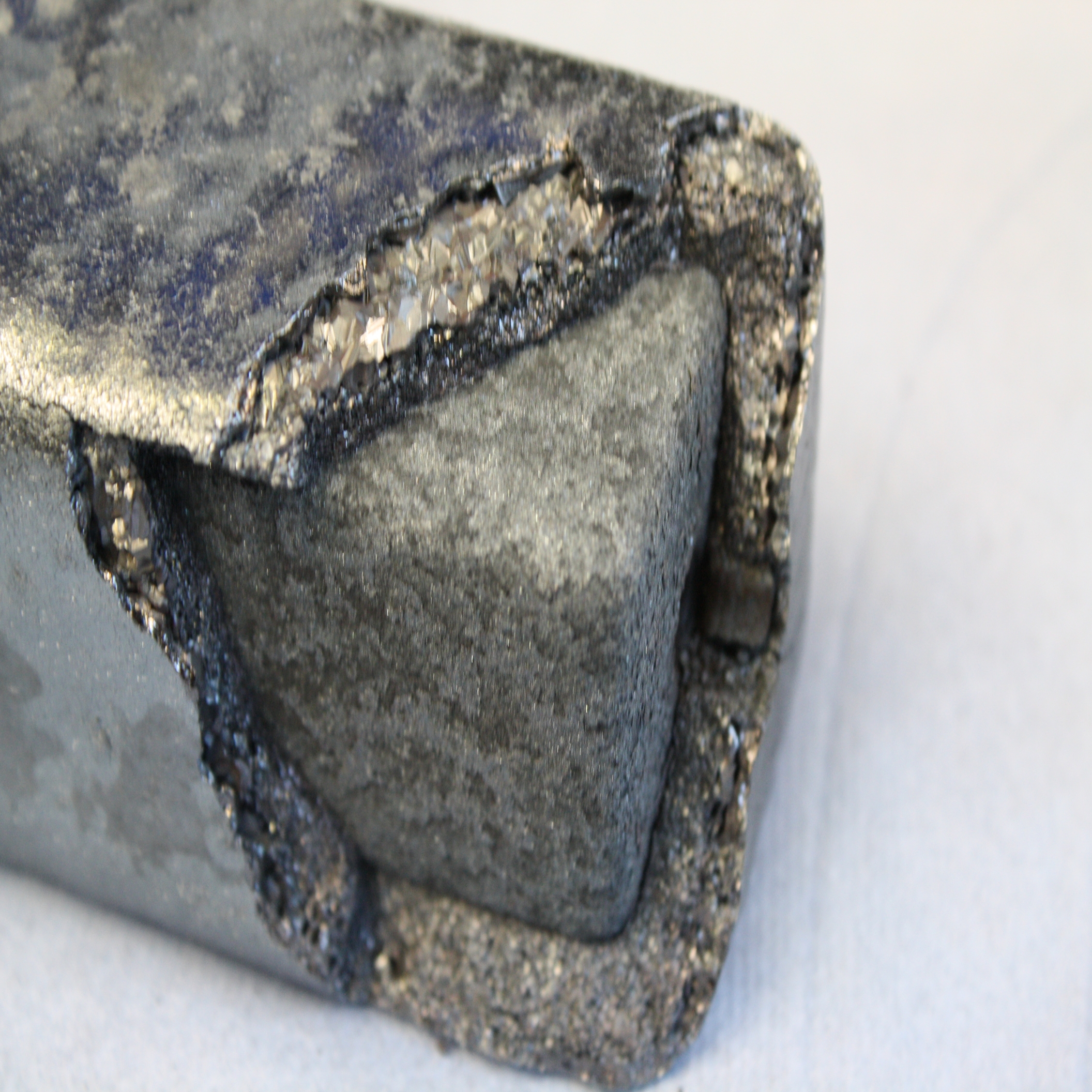

- Surface defects are caused by forged-in scale residues.

- Wear of dies is caused by highly abrasive properties of the scale.

Solution:

- Selection of suitable nanoparticles with properties to minimise scale formation and to condition the scale as a kind of lubricant.

- Screening of various coating concepts in lab scale and analysis of the amount of scale formed and the influence of the scale on the wear mechanisms of the dies.

- Analysis and validation of the interdependencies between coating and substrate.

- Conduction of industrial forging trials.

Operational benefit:

- Conditioning of scale in order to change its function and allow a utilisation of the conditioned scale as a kind of lubricant during first forming step.

- Minimisation of scale formation during inductive reheating by 30 %.

- Minimisation of the wear coefficient by 30 % and increase in service life of the dies (approx. doubled).

partners

Funding reference

13N12832 (BMBF)

Your contact person

6 Martin Wunde, M.Sc.

+49 211 98492-316

martin.wunde_at_bfi.de