OpConDigiCast - Digital Twin Technology for Comprehensive Simulation, Optimization and Control of Continuous Steel Casting Process

Initial situation:

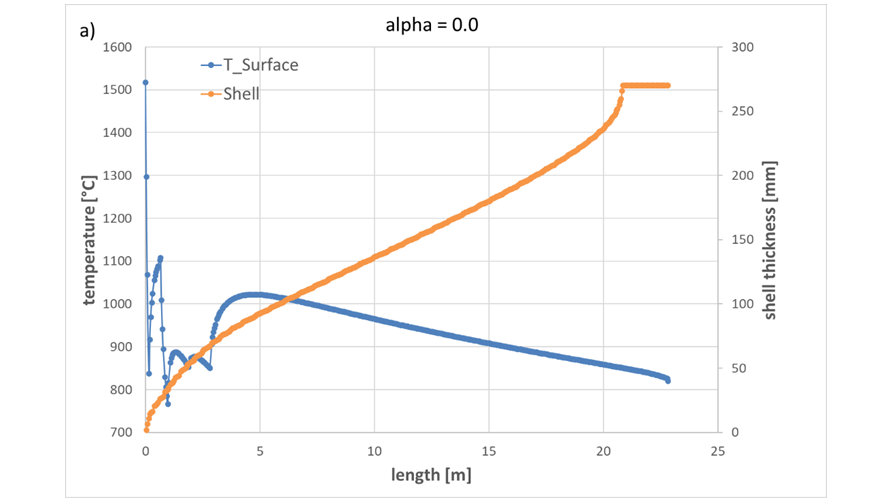

- Semi-finished products manufactured for quality steel grades by continuous casting require precise control of the operating parameters that affect the cooling rate and solidification in order to avoid defects such as cracking at high productivity

- This requires an expanded knowledge base of the complex, mutually influencing processes of mass and heat transport, solidification and thermomechanics that occur during casting

Project targets:

- Development of a digital twin for the continuous casting process of round blooms based on a corresponding comprehensive simulation model

Innovative approaches:

- Validation of the digital twin by evaluating operational campaigns with fibre optical temperature measurements in the mould of a round bloom continuous casting plant

- Virtual experiments with the digital twin to create data-based metamodels of the continuous casting process, which serve to extend simplified dynamic online process models as well as directly for online process monitoring and control

Benefits for the industry:

- Improved transparency and reproducibility of the continuous casting process

- Optimization of operating parameters

- Improved assurance of the required product quality with maximum productivity

- Higher output of steel semi-finished products with lower costs and environmental impact

partners

Funding reference

ZIM / EUREKA

Your contact person

49 Dr. Marc Köster

+49 211 98492-894

Marc.Koester_at_bfi.de