PerMonLiSt - Continuous performance monitoring and calibration of model and control functions for liquid steelmaking processes

Initial situation:

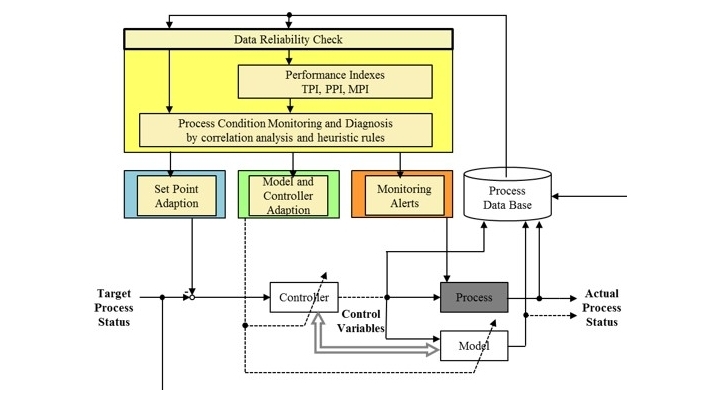

- Analytical process models are used as part of Level-2 automation for observation and control of steelmaking processes. Due to changes in the operation practices, the input materials or the produced qualities, the prediction accuracy of the models and the reliability of set-point calculations is deteriorated.

- For continuous monitoring of process performance, as well as model accuracy and adaptation of model and material parameters, appropriate analysis tools are missing. Thus, the reliability of process models within a Level-2 automation system is not permanently ensured.

Project targets:

- Continuous monitoring of cyclic and acyclic model input data with plausibility check.

- Development of algorithms for continuous monitoring of process as well as of model performance and accuracy.

- Detection of drift and other deviations which are caused by leaving the validation range of the models, e.g. due to changed operation practices or charge / input materials.

- Adaption of model and material parameters to bring accuracy of the models back to the required level (Self learning).

Innovative approaches:

Use of modern methods of control engineering to realize self-learning models even for processes for which only a few and spot measurements of the state variables are available.

Benefits for the industry:

- Extension of Level-2 automation systems by continuous monitoring of the process performance and accuracy of dynamic process models, to determine the reasons for deviation from the optimal performance of the process as well as of the models, and to identify model parameter adaptations to re-establish the required model accuracy.

- Improved achievement of process targets with higher resource efficiency.

partners

Funding reference

RFCS No. 709620

Your contact person

2 Dr. Bernd Kleimt

+49 211 98492-385

bernd.kleimt_at_bfi.de