RekCarb 2 – Recrystallisation of Carbon containing Residuals to Graphene-Nano-Platelets

Initial situation:

The European Community is required by the European Commission's Circular Economy Action Plan to develop sustainable processes. This also applies to methane pyrolysis, which is used for H2 production without the direct generation of CO2, provided that the energy required for this comes from renewable sources. The same applies to the pyrolysis of plastics in plastic recycling processes, where monomers of the polymer used can be recovered. No utilisation in the sense of the circular economy has yet been established for the solid carbon product formed in both processes. However, these can be recycled in the melt recrystallisation process developed in RekCarb. Building on the positive results of the predecessor project ‘RekCarb’, in which the recrystallisation of amorphous to highly ordered graphitic carbon was successfully implemented, the technical development of melt recrystallisation is being driven forward.

Project targets:

To this end, melt recrystallisation will be implemented in a mini-plant, to improve process control and to produce graphene nano-platelets (GNP) in continuous operation. The use of medium-frequency technology will enable continuous cyclic operation and the volume of molten metal can be increased by a factor of 10 compared to the original test facility in the RekCarb predecessor project. Furthermore, a reliable mass and energy balance will be set up so that costs and expenditure for production can be estimated. In addition, the application of GNP in cement mixtures and conductive agent dispersions, for example, will be tested.

Innovative approaches:

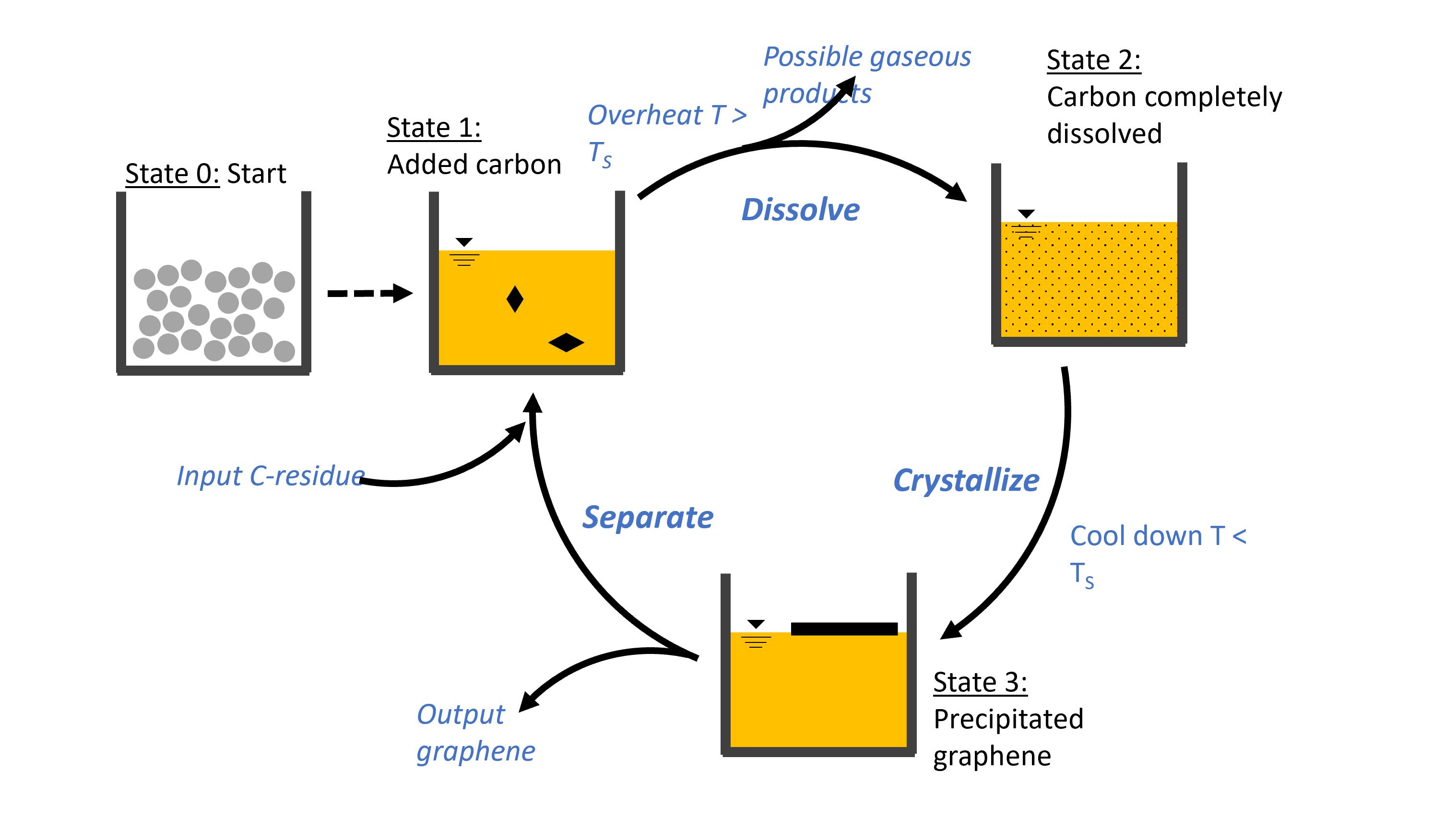

Melt recrystallisation is based on the dissolution of carbon in molten metal to break up the original structure of the carbon and form new graphite crystals. In order to produce GNP, the crystal growth of the formed graphene must be limited at the right time. To do this, the melt is gasified and the GNP formed can then be filtered out of the gas stream. The temperature and gas flow through the melt must be precisely controlled for successful realisation. The research project is therefore developing an optimised system technology in the form of a miniplant for melt recrystallisation.

Benefits for the industry:

SMEs specialising in the production of carbon nanomaterials will benefit considerably from the results. This is because the demand for carbon nanomaterials is constantly growing and at the same time there is a need for a sink for carbon residues.

partner

Funding reference

Your contact person

34 Simon Wölfelschneider, M.Sc.

+49 211 98492-221

simon.woelfelschneider_at_bfi.de