Rolloilfree II - Transfer of aqueous oil free lubricants into steel cold rolling practice

Initial situation:

- Based on the preceding project RollOilFree, oil-free lubricants (OFL) were developed as substitute to the conventional oil-based lubricants in steel cold rolling. Pilot tests showed that it is possible to roll with comparable rolling forces and strip temperatures and to achieve the final strip thickness. The material produced could be further processed without any restrictions. However, the industrial cold rolling tests at high rolling speeds showed that higher rolling forces were required when the OFL was used instead of the O/W emulsions.

- The long-term stability of the OFL showed excellent properties. The OFL showed no corrosive potential on the equipment and the lubrication profile remained constant.

- The effort for maintenance and care can be considered reduced and therefore favorable compared to conventional O/W emulsions.

- Beside necessary process engineering efforts for the maintenance of OF’Ls, the lubricant monitoring needs to be adapted.

- The ecological evaluation regarding the impact on the global warming potential over the whole life cycle shows almost equal performances between OFL and o/w lubricants.

Project targets:

- Successful transfer of oil-free lubricants (OFL) into industrial practice with the support of the RollOilFree II pilot and demonstration project.

- Providing long-term stability of the adapted OFL’s.

- Adaptation of the rolling process engineering to the OFL’s specific characteristics.

- Guaranty of trouble-free further processing in the subsequent production steps.

- Providing of adapted technologies regarding OFL care, recycling and disposal.

Innovative approaches:

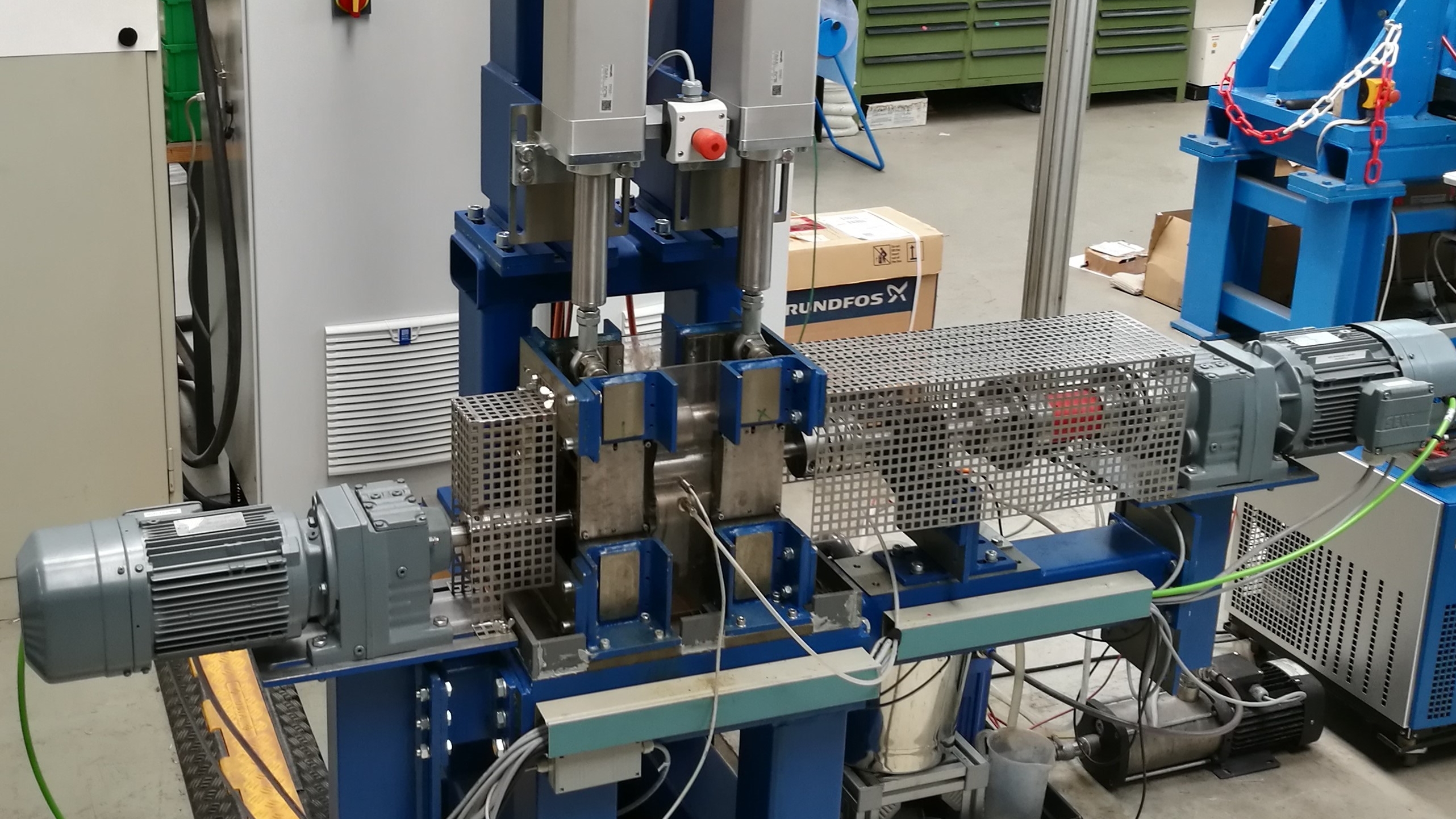

- Adaptation and optimisation of OFL’s to the specific cold rolling requirements (for the automobile and packaging industries) using various test methods.

- Development of online monitoring system for OFL’s.

Benefits for the industry:

- Increase of rolling performance and life time – reduction of cost

- Improvement of strip quality (e.g. improved surface cleanliness, reduced adhesion)

- Simplification of lubricant care (improved handling, reduction of costs)

- Relief of subsequent processes

- Saving of environmental ressources and improved safety and health aspects

- Active participation in the transformation of the energy-intensive steel-producing industry

Further information about the project: RollOilFree II

partners

Funding reference

RFCS 101112433

Your contact person

40 Dr. Delphine Rèche

+49 211 98492-895

delphine.reche_at_bfi.de