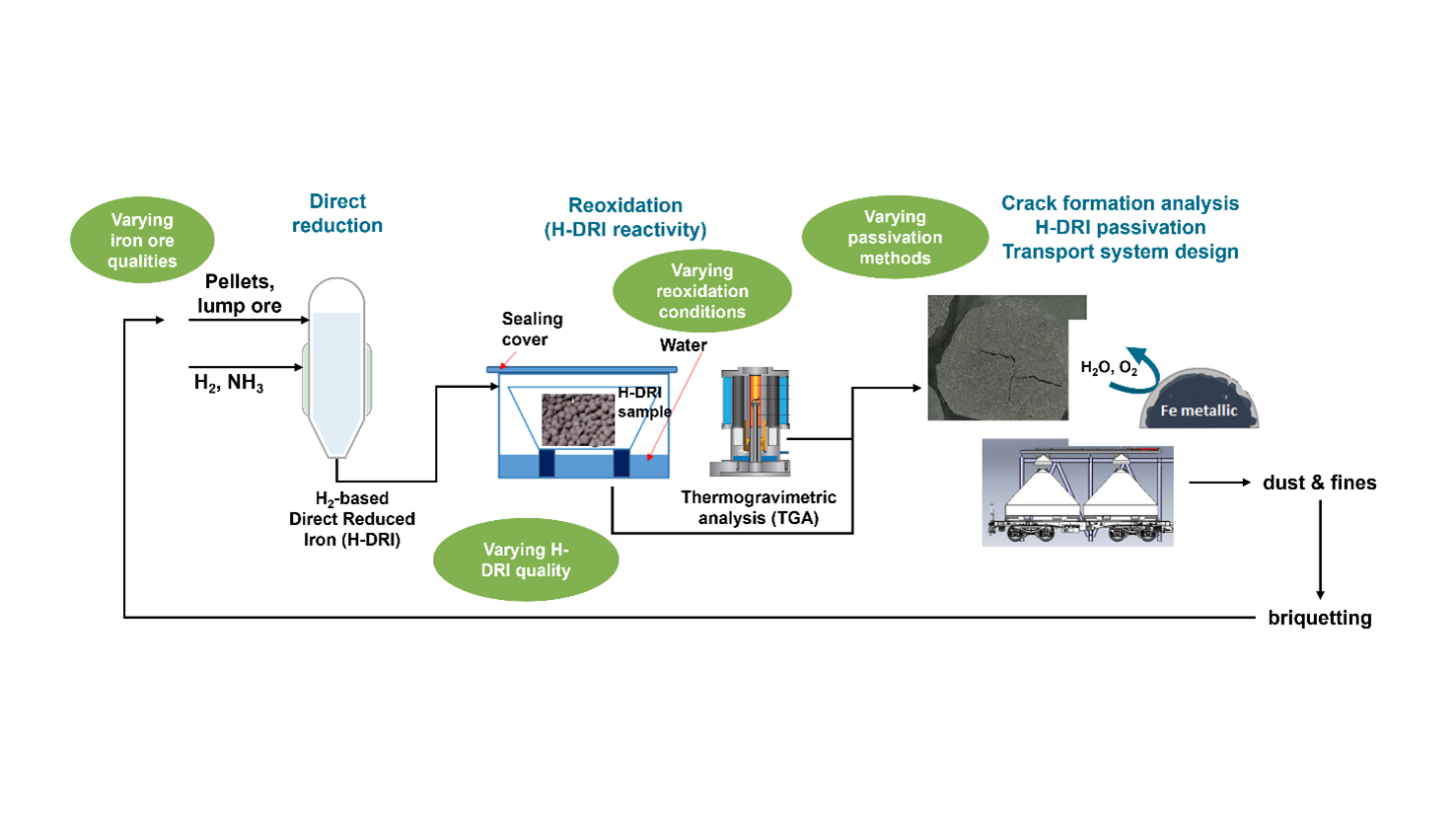

Safe H-DRI - Safe transport of DRI from H2-based direct reduction considering quality-related H-DRI reactivity, stability, the efficiency of passivation methods and health and recycling aspects

©Safe H-DRI project consortium

©Safe H-DRI project consortiumInitial situation:

The project focuses on overcoming key challenges in the safe handling, transport and storage of H-DRI and minimizing risks such as self-heating, ignition and explosions. By researching innovative passivation methods and the reuse of H-DRI fines, safety, sustainability and efficiency shall be improved throughout the steelmaking value chain.

Project targets:

- Development of innovative solutions to handle H-DRI produced using hydrogen.

- Development of methods for the reuse of H-DRI fines

- Contribute to positioning the EU steel industry as a global leader in low-carbon technologies.

Innovative approaches:

BFI has the following innovative tasks in the project:

- Investigation of different iron ore qualities for production of H-DRI pellets (reduction)

- Agglomeration of selected fines feedstock to produce small-scale, pellet-sized samples

- Passivation trials in the hot state e.g. by carburisation with carbonaceous gases

- H-DRI high temperature reoxidation trials in lab/technical scale at different temperatures and inertisation conditions

Benefits for the industry:

- The efficiency of passivation methods to prevent hazards and risks from reoxidation (self-heating, ignition, local explosions) during transport and related handling will be quantified.

- The innovative knowledge regarding H-DRI behaviour will contribute to an updated transport system standardization and extend existing or new transport guidelines.

Further information about the project:

Project duration: 1.10.2024 bis 31.03.2028

Funded by:

Funding reference

RFCS Project Nr. 101150482

Your contact persons

56 Alexa Kala, B.Eng.

+49 211 984-92-225

alexa.kala_at_bfi.de

37 Dr. Ralf Wolters

+49 211/98492-573

ralf.wolters_at_bfi.de