SafeDewPoint – Acid dew point and corrosion sensors for dynamic waste heat recovery from steel mill flue gases

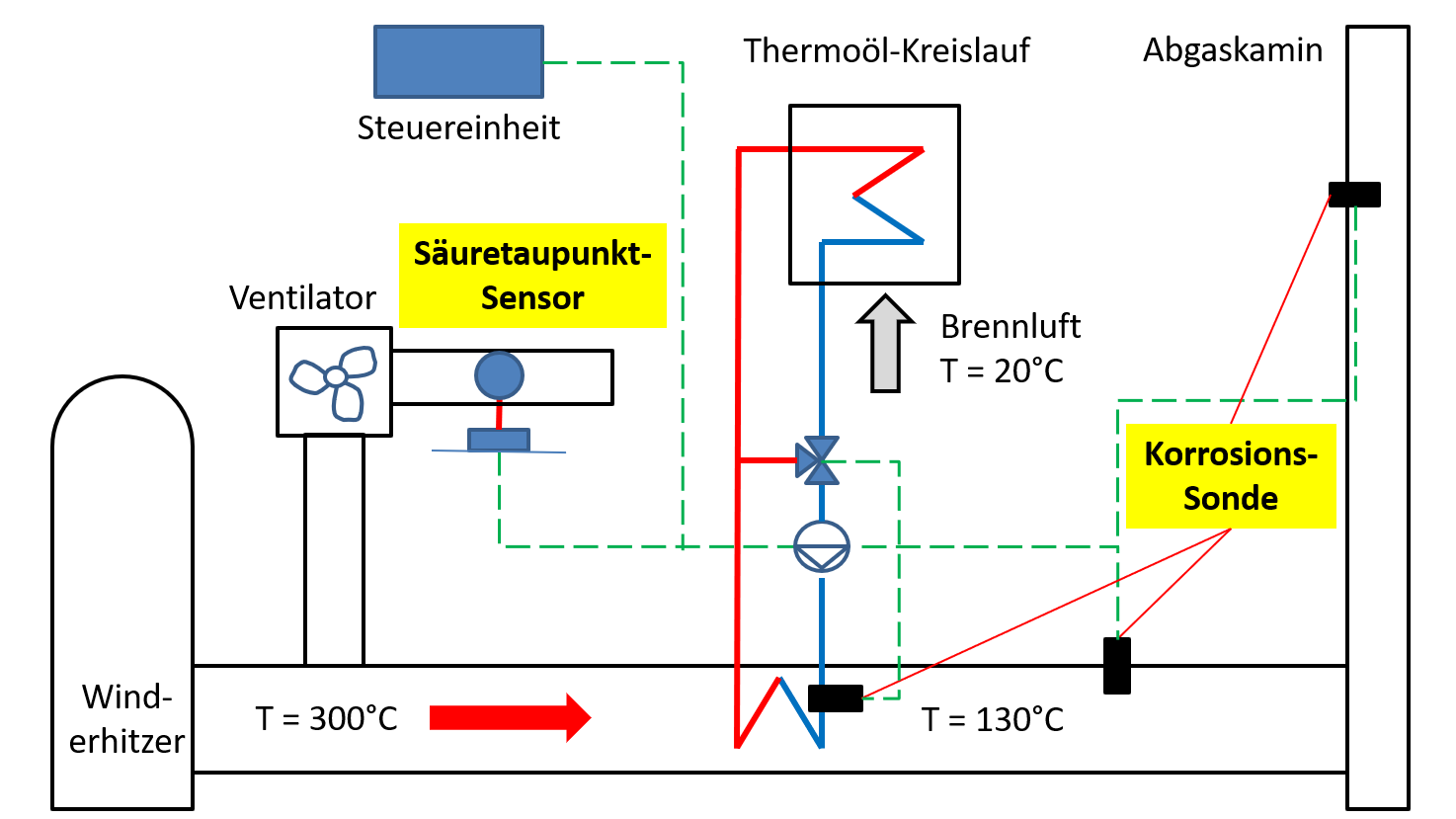

During combustion of steel mill gases acid dew point temperature varies strongly. SafeDewPoint aims to recover waste heat in hot blast stoves, power plants and reheating furnaces by dynamic adjustment of flue gas temperature above the acid dew point. This will be reached with a help of novel inline acid dew point sensor and corrosion probes. This system will enable direct reuse of up to 20% waste heat. The project addresses waste heat utilisation for the preheating of fuel gas, combustion air and boiler feed water. For EU it will result in a potential for savings of 107 million €/y or 3570 GWh/y and emission reduction of 720 ktCO2/y. It will support competitiveness and sustainability of European integrated steel plants.

Downloads

EUROCORR 2022 presentation paper, 28th August - 1st September 2022, Berlin/Germany

EUROCORR 2022 presentation Topic: Corrosion by Hot Gases and Combustion Products

partners

Funding reference

Your contact person

11 Dr.-Ing. Pavel Ivashechkin

+49 211 98492-321

Pavel.Ivashechkin_at_bfi.de