SMARTER - Steam and gas network revamping for the steelworks of the future

Initial situation:

The steel industry is an Energy Intensive Industry and is therefore appointed as a major source of CO2 and other emissions. Every regulation originated from European or local government hits the steel industry to a great extend due to the extraordinary market situation combined with the dramatically lower environmental requirements of the competitors form outside the EU. To be able to produce at competitive prices, the EU Steel sector made and is making big efforts to improve energy efficiency by saving energy costs.

Steelworks transform, store, transmit and use various types of energy, where electricity, off- and by-product-gases and steam are among the most important ones. In order to comply with the goals of the Green Deal, steel producers constantly improve their networks and associated management practices in order to reduce the waste of resources and increase the overall efficiency.

Project targets:

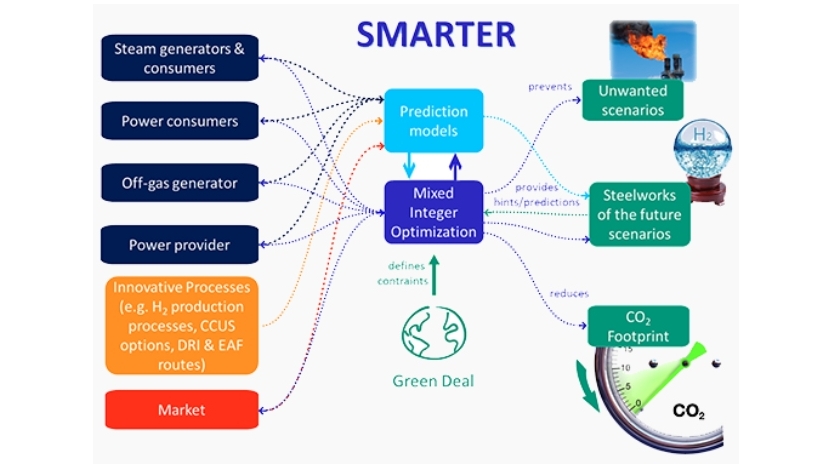

The project aims at optimising the management and the structure of the steam and gas networks inside integrated steelworks in the light of the future developments of the steel production. The availability of efficient and optimized gas and steam networks is fundamental for the optimal management of the steelworks of the future, such as it is for the more traditional one, where it is recognised as a fundamental element to reduce CO2 emissions, energy consumptions, and related costs. Therefore, structural modifications of the networks are considered together with innovative processes and production units, such as DRI/EAF route including natural gas and hydrogen exploitation, which can affect the behaviour of the networks.

Innovative approaches:

The innovative content of the project is based mainly on the following aspects:

- Considering changing plant configurations, as they are usually caused by updates, revamping and restructuring, is a central innovative core of SMARTER.

- Including possible integration scenarios of C-lean production units (e.g. DRI/EAF route including NG and hydrogen exploitation) among the above-mentioned changing plant configurations is also innovative, as it allows considering how such processes impact and can coexist with traditional ones in a future transition phase which is expected to have a not negligible duration. This also introduces a medium-long term perspective of exploitation and deployment of the research outcomes.

- Distributed real-time calculation of the optimization is novel and will be significant innovative aspect for the EU Steel Industry, as the project explores how such an approach can be put into practice.

- Speeding up the MI solution algorithm is innovative and a benefit also for the scientific community and other “users” solving MI problems.

- Rigorous application of latest machine learning technology, including Deep Echo State Networks and Physics-Informed Neural Networks allows a modelling that is not only data based, but essentially also applies physical principles.

- Introducing key communication elements like CO2 reduction, ecological energy distribution and reduction of waste as core targets for real technical optimization at a plant is a new stage of connecting EU research objectives into the innovation process.

Benefits for the industry:

- Reduction of CO2-Emissions.

- Reduction of maintenance costs due to a dedicated choice of preferred steam producers entailing a more continuous use of the steam producers with less power On/Off switching.

- Avoidance of natural gas driven steam production using best practice of flexible two-directional steam pipe junction between steelworks and power plant together with foreseen mixed integer optimization approach of SMARTER. Only the optimization of the overall network will deliver additional benefits for this completely new steam pipe junction which will be erected end of 2021.

- Increase of regenerative production of electricity by blast furnace off-gas by avoiding production of unnecessary steam amounts.

- Optimization of energy usage considering market prices and energy availability.

- Reduction of noise emissions by uncontrolled steam emissions due to missing forecast and missing optimization of steam mass flows in the network

- Future developments in regenerative energy technologies like hydrogen in steel production will be covered as well by adaption of the modular approach of the optimization.

partners

Funding reference

Your contact person

46 Dr. Andreas Wolff

+49 211 98492 250

andreas.wolff_at_bfi.de