SteamDry - Superheated steam drying for sustainable and recyclable web-like materials

Initial situation:

Drying is the most energy intensive unit operation in every paper and board production line. Superheated steam drying technology enables significant reduction of energy used in drying. This is possible due to almost complete recovery of supplied latent heat which is not possible for drying technology used today on production lines. As shown in previous research, a theoretical energy savings potential up to 80% can be reached. This will lead to equal or higher CO2 emission-savings, depending on the primary energy used for electricity production.

Project targets:

The SteamDry project aims to significantly decrease energy consumption and CO2 emissions in the paper and board manufacturing industry by showcasing a concept that achieves a remarkable 60% energy savings in thermal drying and 40% energy savings on a production line, with the potential for up to 100% CO2 emission reduction.

Innovative approaches:

- Development of a digital twin based on a fast surrogate model of a compressor, steam cleaner, heat exchanger, compressor, auxiliary units, and dryer. This twin-platform is used to simulate the control and management strategy.

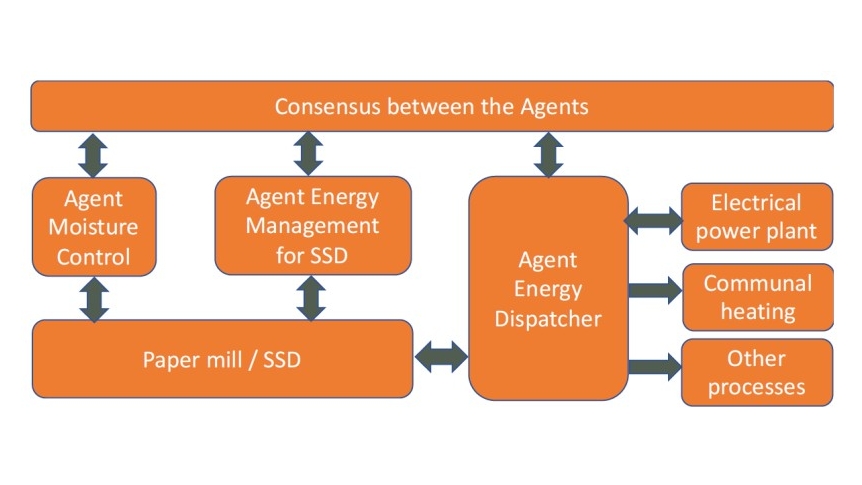

- Design an IT architecture to support the distributed agent structure. It will be selected from earlier research and development e.g. from earlier Horizon Europe (HE) projects and adapted to process industry.

- Development of model- and data-driven reinforcement learning control for the dryer (aim stabilisation of process, optimal operating, energy) and distributed data-driven Artificial Intelligence (AI) based energy management system of the overall process based on multiagent reinforcement learning.

- Development of a data and/or model driven AI based anomaly detection system for the paper mill e.g. for early detect fouling for heat exchanger and triggering counter measurements.

Benefits for the industry:

- Long-Term Impact:

In the long term, the SteamDry project anticipates substantial energy savings, estimating a potential of 127 terawatt-hours (TWh) or 6 billion euros annually for paper and board manufacturers in Europe. The global annual energy savings potential amounts to 870 TWh, nearly seven times that of Europe's savings and market potential combined. - Competitiveness and Resilience:

Enhancing the competitiveness of the paper industry is essential for job retention and economic sustainability. Reducing the climate impact of paper and board manufacturing fosters resilience in rural communities, where a significant portion of production units is situated. This, in turn, augments companies' capabilities to invest and operate efficiently, contributing to overall economic and environmental sustainability. - Unlocking Opportunities:

The developed solution is versatile, capable of installation on existing infrastructure or new-built machines with low CAPEX and OPEX, thereby opening new opportunities for technology suppliers and providing cost savings for users. The SteamDry concept is expected to enable technology suppliers to boost their revenue by an estimated 230-345 million euros annually in Europe.

partners

Funding reference

Your contact person

48 Alexander Dunayvitser, M.Sc.

+49 211 984-92-609

alexander.dunayvitser_at_bfi.de