SufConInspect - Enabling zero-defect manufacturing for flat steel production by means of optimized inspection results and a new level of online surface quality control

Initial situation:

Resource-efficiency and competitiveness are main aims of the European Green Deal transformation. In this global restructuring process yield improvement and reduction of waste aimed at by a zero-defect production are low-cost opportunities for European steel manufacturers to realize a more sustainable production.

Enabling zero-defect manufacturing for flat steel production requires an early detection of surface defects and a fast and adequate control action once a defect appears. Therefore, the European flat steel producers ultimately require automatic online surface quality control systems reacting to appearing surface defects in real-time. Indeed, modern steel production plants are equipped with a wide range of sophisticated control systems dynamically controlling measurable product properties like thickness or flatness, but referring to the state of the art for surface defects no comparable system exists.

Project targets:

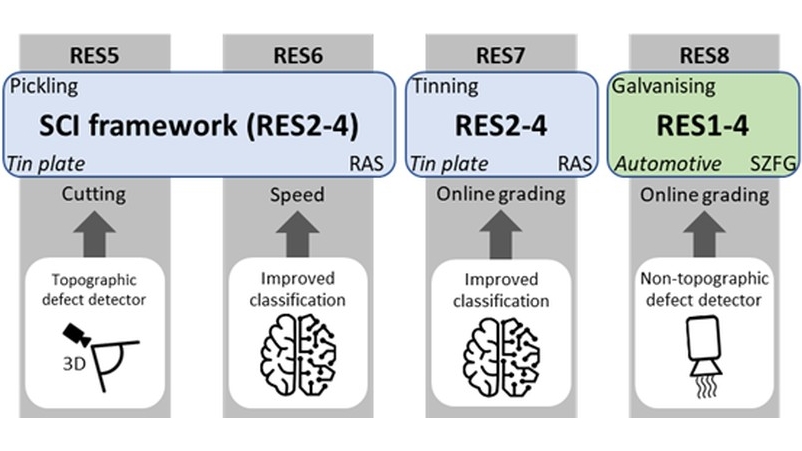

The SurfConInspect project aims to bolster the European steel industry with a distributed online control system providing precise quality information for robust control actions. Demonstrations in four industrial use-cases, focusing on tin-plate and automotive production include automated cutting control at a tin-plate pickling line, optimized process speed control based on coil scale affection and improved quality control at tinning and galvanizing lines through online grading and in-coil control actions.

Innovative approaches:

- Implementation of automated cutting control for heavy defects at a pickling line (PL) of tin-plate production to prevent strip breakages at subsequent processes.

- Optimized control of the process speed at the pickling line based on the scale affection of the individual coil.

- Improved quality control at tinning lines (TL) through the realization of online grading based on various surface defect types and generation of optimized in-coil control actions.

- Improved quality control at galvanizing lines (EGL) through the realization of online grading based on various surface defect types and generation of optimized in-coil control actions.

Benefits for the industry:

- Improved yield will lead to decrease in energy consumption, waste and CO2 emissions of European Steel Industry.

- Reduction of coil breaks and production losses will increase resource-efficiency and competitiveness of European steel manufacturers and leads to a more sustainable production.

- Reduction of customer claims will lead to a higher customer satisfaction, improving the image of the European Steel manufacturers and thus contribute to save costs.

- The reduction of coil breaks at tandem and continuous annealing lines will increase working safety due to lowering the risk of serious incidents.

- Easier and better supported decision-making processes will lead to improved working conditions of flat steel production line operators and a higher employee satisfaction.

Further informationen about the project:

partners

Funding reference

Your contact person

9 Dr. Jens Brandenburger

+49 211 98492-229

jens.brandenburger_at_bfi.de