SunShine – Sustainable new casting and rolling process monitoring / sensoring approach aimed at proper surface quality and shape in flat and long products

Initial situation:

- Non-uniform in-mould solidification in long term and flat products can lead to shape and surface defects affecting as-cast quality and continuous production flow

- Decreasing the number on products which have to be scrapped due to defects would reduce the CO2 emissions significantly

Project targets:

- Identification of casting parameters which lead to product defects and of steel grade families which are mostly affected

- Development of AI / machine learning tools to identify correlations between casting parameters and defects

- Definition and application of recommendations and rules to predict and avoid the occurrence of defects

- Identification of optimal practices to obtain faster billets transfer to subsequent reheating furnace and welding before rolling

Innovative approaches:

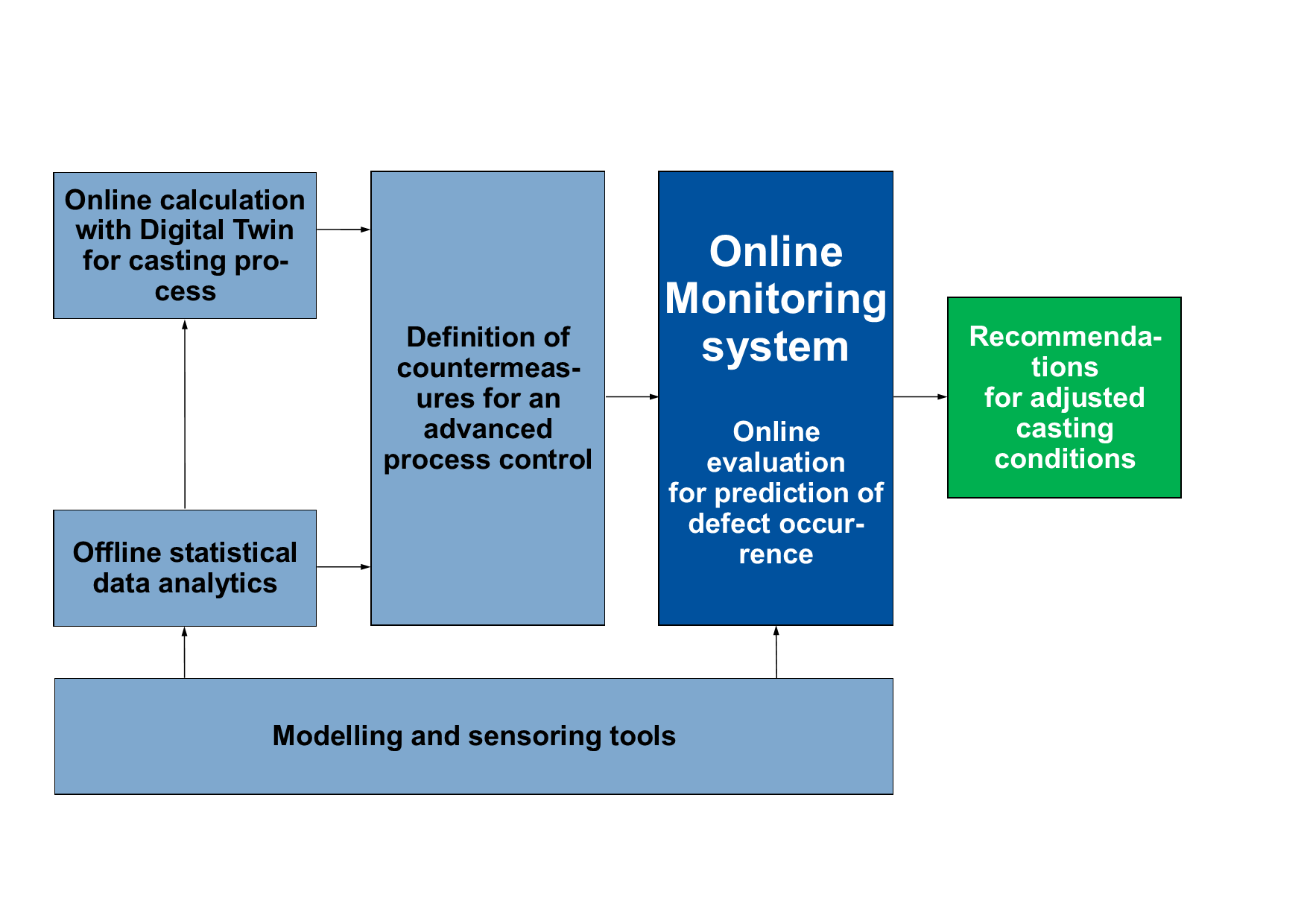

- Setup of simulation models for solidification and thermomechanical processes

- Installation and industrial test of different sensors for online assessment of casting conditions, for detection of defects and for online control of casting parameters

- Installation and long-term testing of prototypes on dedicated IIoT platforms

Benefits for the industry:

- Reduction of shape and surface defects occurrence in as-cast products

- Decrease of CO2 emissions due to reduction of scrapped material

- Energy savings and reduction of material losses due to improved connection between casting and rolling

- Increase of productivity

partners

Funding reference

RFCS 2023

Your contact person

49 Dr. Marc Köster

+49 211 98492-894

Marc.Koester_at_bfi.de