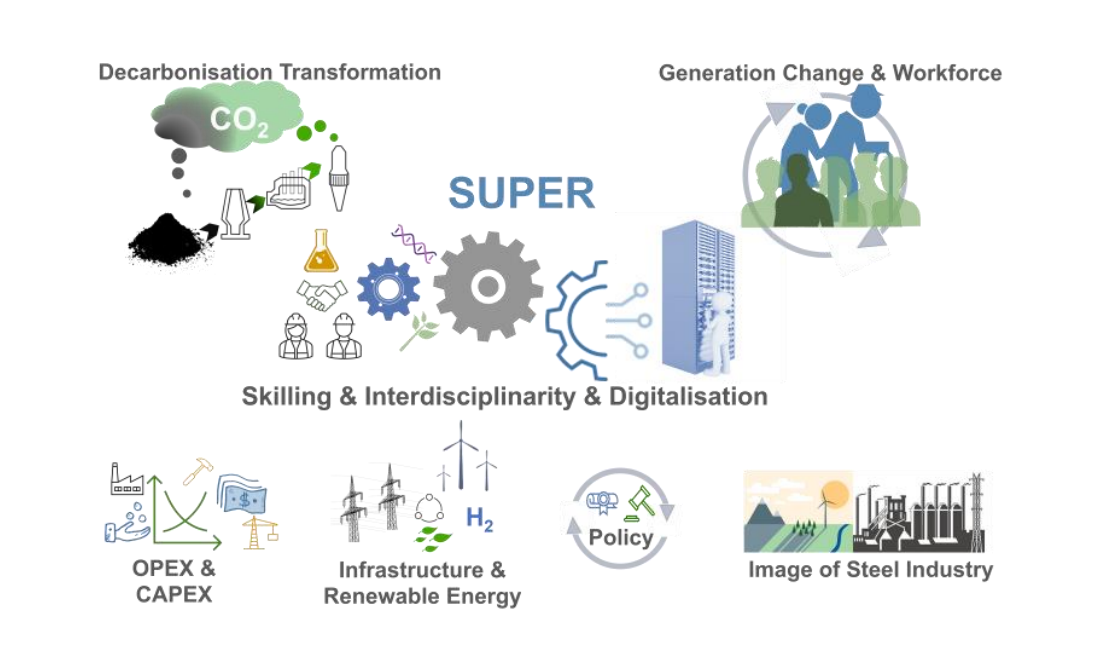

SUPER - Sustainable future steel production and people recruiting and skilling

Initial situation:

- The European steel industry is facing a dual transformation: the decarbonisation of production processes and demographic change within the workforce.

- Comprehensive technological adjustments are necessary to achieve European climate targets, including new processes, plant concepts and alternative energy sources.

- At the same time, the upcoming generational change is leading to a loss of experiential knowledge, while the recruitment of qualified young talent is becoming increasingly important.

- The industry is therefore faced with the task of increasing its attractiveness and highlighting its potential as a key driver of a climate-neutral industry.

- Parallel to the ecological transformation, the digitalisation of production and value chains is advancing: sensor technology, data analysis and AI-based systems require new skills and adapted working methods.

- Both developments (decarbonisation and digitalisation) require new strategies, targeted training measures and investments under challenging economic conditions.

Project targets:

- Supporting the decarbonisation of the European steel industry by building, promoting and disseminating knowledge about new technology pathways, processes and use scenarios.

- Defining four key technology routes for low-carbon steel production and developing nine decarbonisation scenarios for 2050, taking into account energy and raw material requirements.

- Promoting the transformation of the world of work through targeted recruitment and training measures, in particular to attract young talent, with a special focus on equality and sustainability.

- Workshops, surveys, webinars and a practice-oriented training event (‘RACE’) to strengthen interest in the industry and impart knowledge in a practical manner.

- Digital communication and dissemination channels (website, LinkedIn) for continuous knowledge transfer, networking and visibility of project results.

- Recommendations for action and political initiatives to better link decarbonisation and the transformation of the world of work through increased interdisciplinary cooperation.

Innovative approaches:

- Development of a systematic methodology for identifying, evaluating and integrating promising decarbonisation technologies along the entire steel value chain.

- Development and continuous updating of technology roadmaps and transformation scenarios (2030, 2040, 2050) based on current research results, stakeholder surveys and framework condition analyses.

- Integration of technological, economic and infrastructural framework conditions, such as the availability of hydrogen, electricity and scrap, into dynamic scenario analyses for strategic decision support.

- Use of a multidisciplinary, data-driven approach to rapidly update existing models and promote synergies between industry, research and politics.

Benefits for the industry:

- Identification and evaluation of current and future decarbonisation technologies along the entire steel value chain for the further development of existing technology and transformation scenarios.

- Support for strategic investment decisions through reliable industrial future scenarios up to 2050, taking into account technological maturity, energy requirements and economic conditions.

- Strengthening competitiveness through new decision-making and management approaches for cross-sector coupling of energy and industrial systems.

- Improving recruitment and training by introducing the ‘RACE’ concept in the steel industry and by evaluating and further developing existing training programmes (e.g. Steelmaster, Eurosteelmaster).

- Increasing the attractiveness and image of the steel industry among young talent through practice-oriented training, events and targeted communication measures.

- Supporting the transformation towards a digital, climate-neutral and socially sustainable ‘Steel Industry 5.0’ by combining technological, qualification and political recommendations for action.

Further information:

Project Website: https://www.project-super.eu/

LinkedIn: https://www.linkedin.com/company/project-super/

partners

Funding reference

RFCS, Projektnummer: 101216382

Your contact person

61 Jonas van Bracht

+49 211 98492-282

jonas.van-bracht_at_bfi.de