SUSTAINTAP – Blast furnace sustained tapping practice

Blast furnace sustained tapping practice

Initial situation:

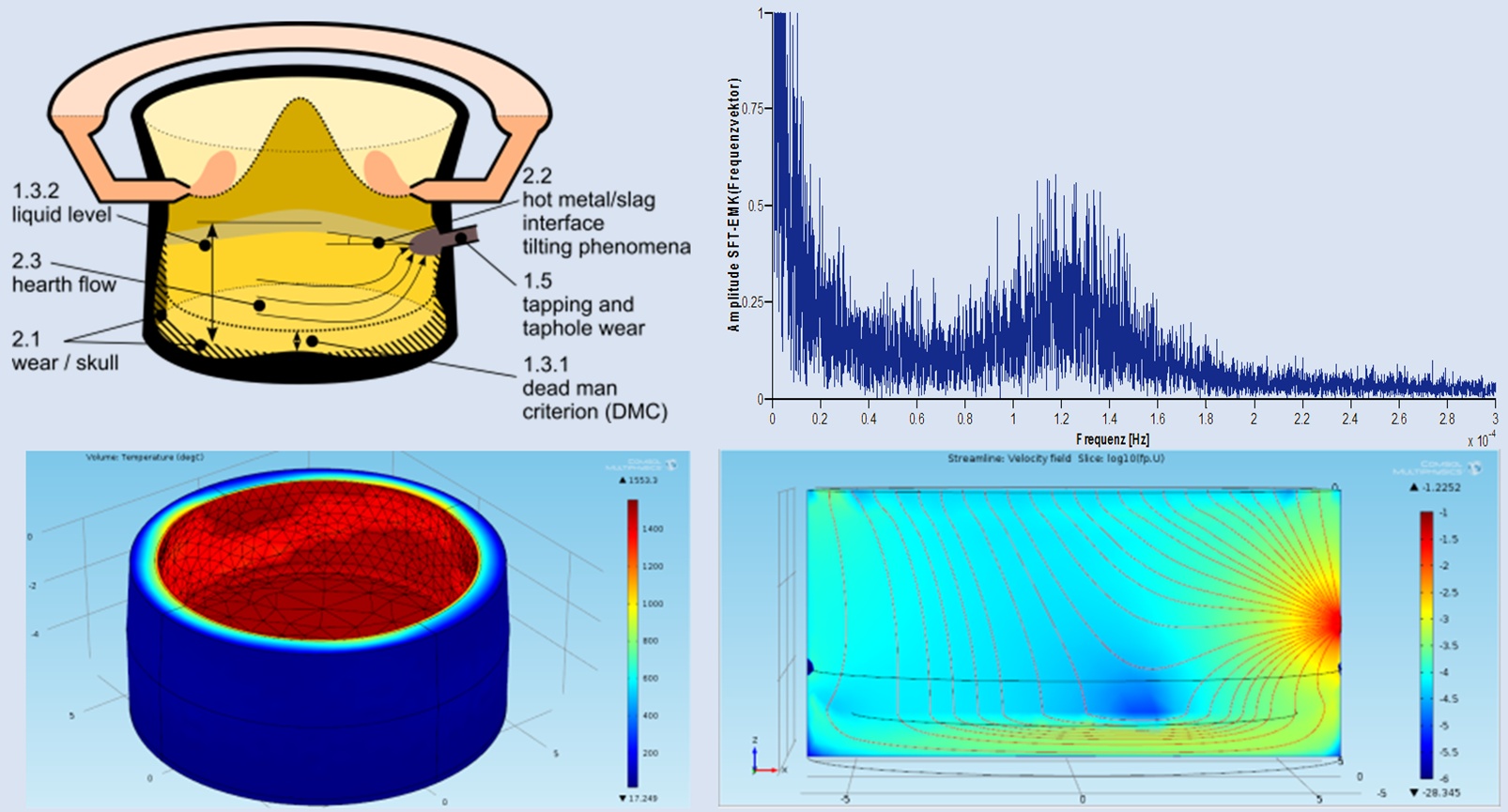

- Unknown position and voidage of the dead man.

- Uncertainty concerning liquid levels of iron and slag.

- Hearth wear calculated only in 2D sections.

- Influence of hearth flow on wear calculations.

Work topics in the project:

- Estimation of position and voidage of the dead man from operational data.

- Estimation of liquid levels from EMF data.

- Calculation of the hearth wear under consideration of the hearth flow and dead man properties.

Expected results

- Online models for liquid levels and dead man state.

- 3D hearth wear model.

- 3D hearth flow model as well as models of the iron – slag interface tilting and tap hole flow.

partners

Funding reference

RFCS-CT-2012-00001

Your contact person

7 Dr. Thorsten Hauck

+49 211 98492-301

thorsten.hauck_at_bfi.de