TailoredZA - Tailored structure of multi-layer zinc alloy coatings to improve forming and corrosion protection properties

Initial situation:

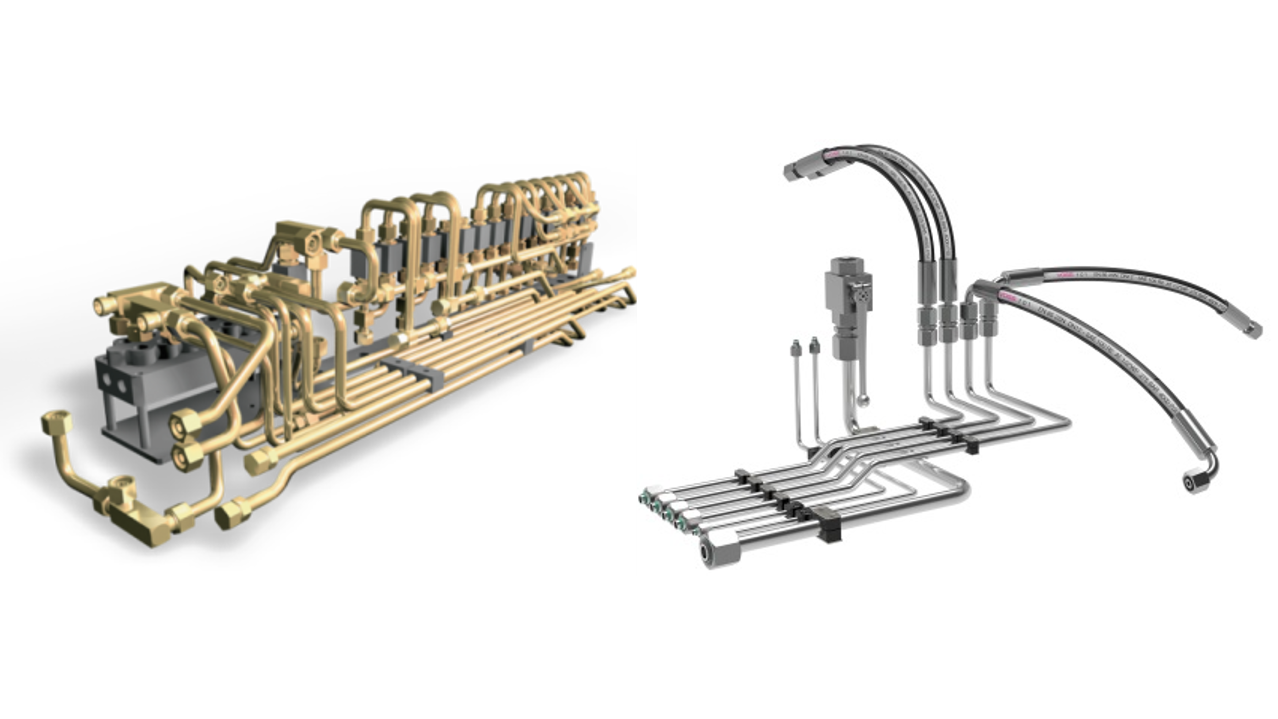

- Galvanised and passivated steel pipes are highly bent for many applications and are also cold-formed at the joints.

- At high degrees of deformation, the passivation layers can partially crack and the zinc layers can be damaged.

- Corrosion therefore occurs more frequently in the heavily deformed areas of the components and reduces their service life.

Project targets:

- Improvement of the ductility and corrosion resistance of the corrosion protection layers after mechanical stresses such as bending or flanging by electroplated zinc alloy layers with an innovative layer structure.

- Fundamental electrochemical investigations of zinc alloy deposition at high current densities.

- Research into multilayer zinc alloy coatings with an innovative coating structure and investigation of the application properties.

Innovative approaches:

- Use of the “concept of graded materials”: Optimization of stress states during forming and avoidance of crack formation through multi-layer or graded layer structure with an increase in ductility towards the substrate.

- Application of pulse plating techniques to improve the coating properties (ductility, corrosion resistance).

Benefits for the industry:

- Improved ductility and corrosion resistance of the coatings after mechanical load such as bending or flanging.

- Contribution to environmental compatibility by abandoning passivation containing chromium VI and cobalt.

partners

Funding reference

13XP5026D, gefördert vom BMBF

Your contact person

36 Dr. Andreas Bán

+49 211/98492-314

andreas.ban_at_bfi.de