TriboSim - Experimental and simulative evaluation of wear on roll coatings

Initial situation:

- Increased wear on work rolls due to increased use of ultra-high-strength steels in automotive production

- Use of toxic and carcinogenic chromic acid for wear-reducing hard chrome plating of rolls

- Costly plant trials required for the development of new roll coatings

Project targets:

- Development of an experimental and numerical method for the evaluation of wear protection coatings for forming tools under the specific process parameters of cold rolling of steel strip

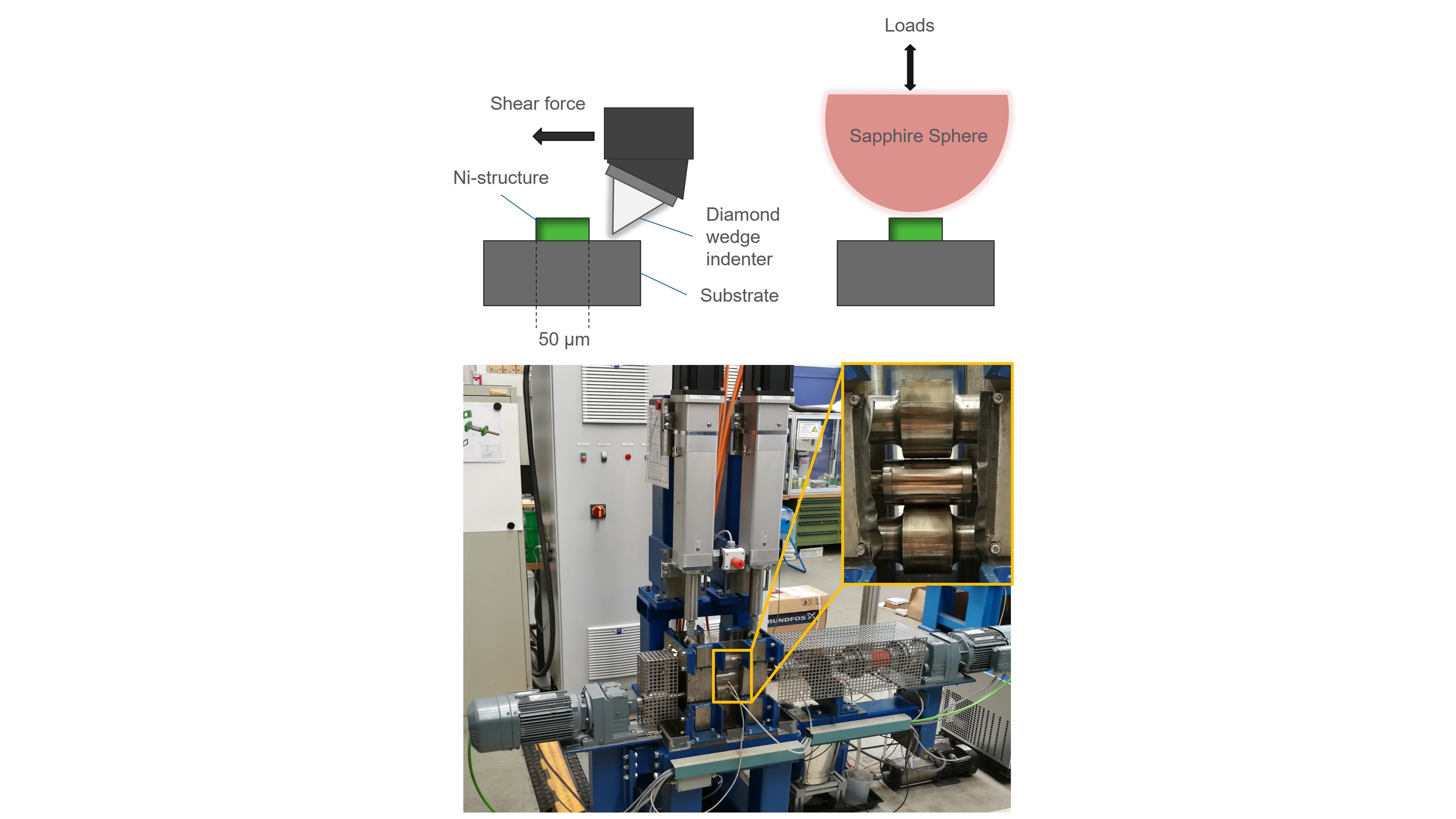

- Development of new micro-testing methods for cyclic loading and quantitative determination of the adhesive strength of metallic coatings

- Numerical simulation of layer failure under the specific conditions of cold rolling (project part of the Institute of Metal Forming of the RWTH Aachen University)

- Process-related investigation of coating wear and evaluation of the simulation tool in a

- 3-roller wear test rig

Innovative approaches:

- First-time determination of adhesive shear strength by shearing of chemically deposited nickel microstructures using a nanoindenter

- Development of process models at macro and meso level for estimating the delamination risk of work rolls coatings (project part of the Institute of Metal Forming of the RWTH Aachen University)

Benefits for the industry:

- Optimization of wear protection e. g. by adapting the coating/roll material

- Extending the service life of the rolls and increasing the surface quality of the strip

- Improved and REACH-compliant coatings

partner

Funding reference

IGF-No. 20238 N/1

Your contact person

36 Dr. Andreas Bán

+49 211/98492-314

andreas.ban_at_bfi.de