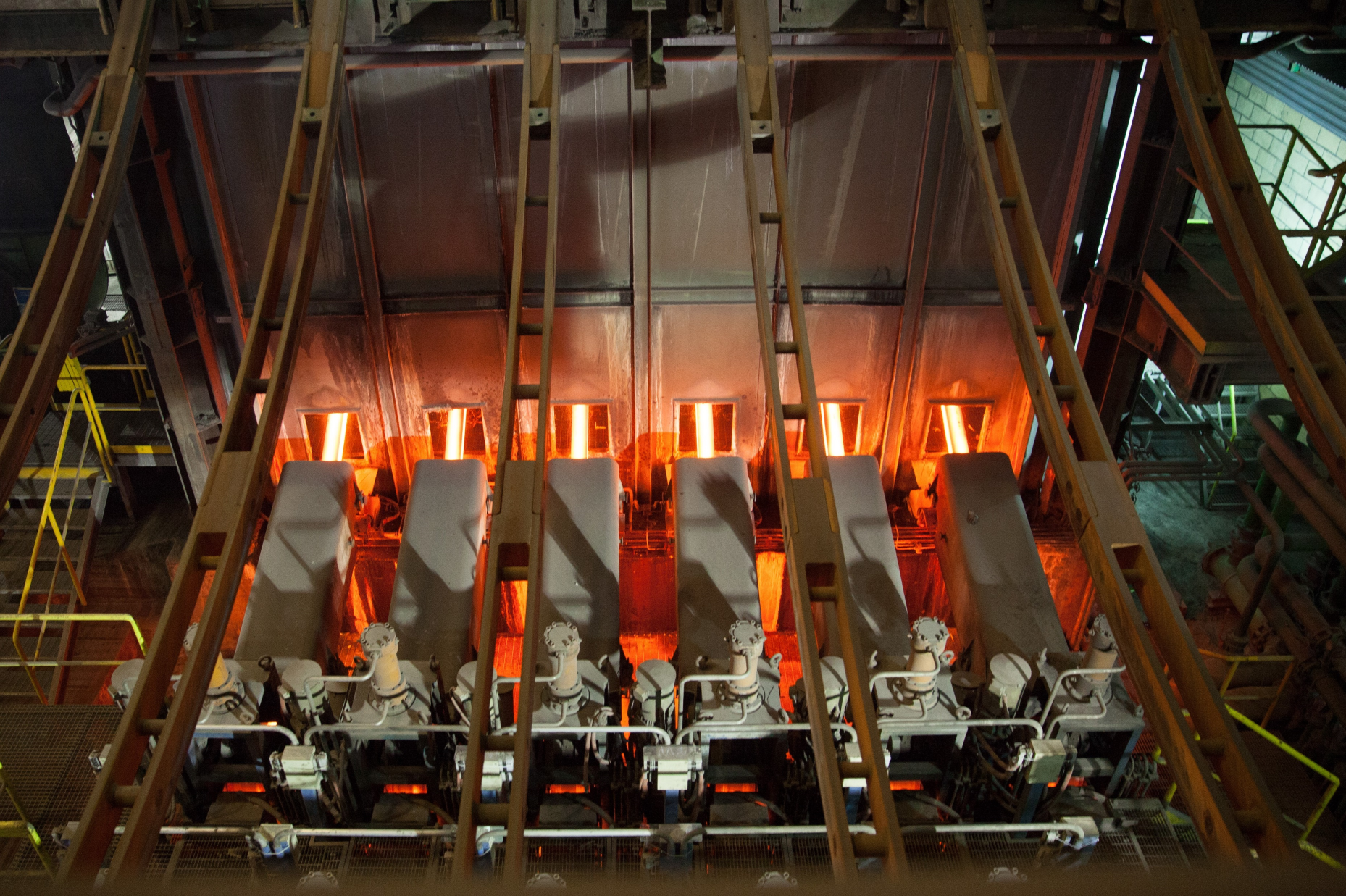

ConSolCast – Comprehensive modelling, monitoring and control of solidifcation for optimisation of continuous casting process

Initial situation:

- Safety, costs, productivity, yield, product quality and delivery on time are performance indicators of the casting process.

- A strand breakout is the event which has negative effect on all these indicators.

- New steel grades, increasing casting speeds and quality requirements of the customers raise the need for further improved monitoring, optimisation and control of the process to avoid such an event.

Project targets:

- Improved monitoring of the strand solidification during continuous casting processes

- Significantly reduced breakouts on a casting machine and surface defects on the strand

- Determination of optimised casting parameters for different steel types

- Provision of sufficient information for the casting operators to make proactive decisions regarding changes of casting conditions

Innovative approaches:

- Application of innovative measurement techniques at the mould and at the crater end position

- Mathematical modelling of temperature field and solidification front

- Auto-calibration procedures for boundary condition models using results from operational trials

- Dynamic control strategies for mould and spray water cooling based on predictive online models

- Alarm system regarding poor in-mould conditions and possible breakout events or surface defects

- Standardised methodology for breakout investigations, attended by improved casting procedures and casting machine adjustments

Benefits for the industry:

- Improved reliability and stability of the continuous casting process with (almost) eliminated breakouts

- Reliable achievement of the target values with respect to temperature profile, shell thickness and crater end and therefore improved confidence when casting new steel grades

- Improved quality in terms of the as-cast product

- Optimised operation of torch cutting behind crater end position

- Increased productivity of casting machine with minimisation of resources consumption

Please find further information in the article

Measurement and Model-Based Control of Solidification in Continuous Casting of Steel Billets

partners

Funding reference

RFCS 2017

Your contact person

49 Dr. Marc Köster

+49 211 98492-894

Marc.Koester_at_bfi.de