The BFI

For more than 50 years we have been proposing and developing solutions to meet your current and future challenges. We see ourselves as your research partner, putting our special expertise and long experience at your service in translating new findings into industrial practice.

As a non-profit research institute we maintain close contacts with the process industry.

Current construction progress of our direct reduction pilot plant

Follow the progress of the construction of our direct reduction pilot plant: The embedded video is updated regularly and clearly documents the individual construction phases – from the preparatory measures to the commissioning of the plant.

The construction of the direct reduction pilot plant lays the foundation for supporting industrial, climate-neutral steel production in Duisburg. Together with the ‘DRI smelter’ research project, the pilot plants will simulate future steel production and answer key technical questions about the safe and trouble-free operation of large-scale industrial plants.

Many thanks to the Federal Ministry for Economic Affairs and Energy for funding this important real-world laboratory ‘H2Stahl’ for the transformation of the German steel industry.

Check our website regularly to see the next milestones.

Further information about the project:

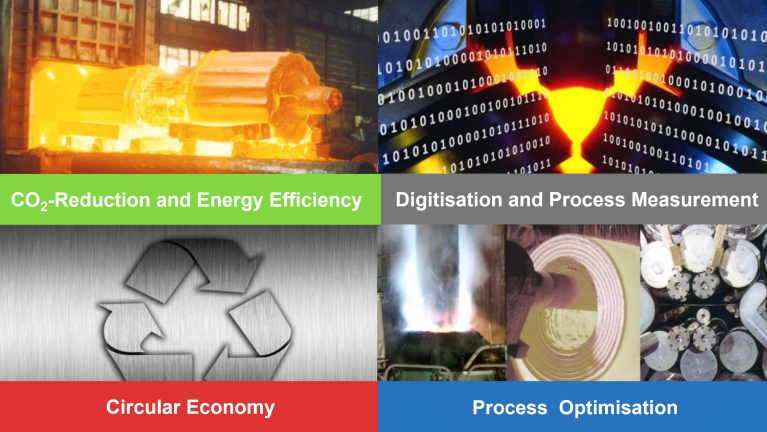

Core compentencies

The BFI focuses on four key areas that are of outstanding importance for the entire steel and process industry. In order to actively help shape the present and future, we not only react to developments, but also drive them forward across all departments in the four key areas. This is how innovative ideas become concrete applications and knowledge becomes economic performance.

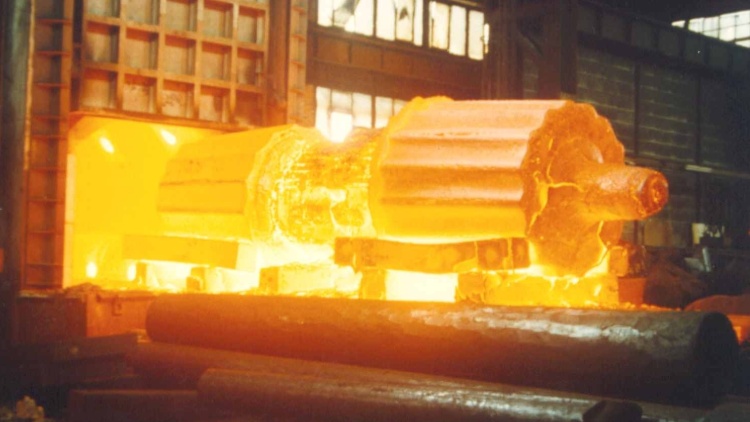

CO2 reduction and energy efficiency

Reducing energy requirements and emissions such as CO2 are important political climate targets that we want to achieve together with the process industry and plant engineering through new solutions.

Digitisation and process measurement technology

Supporting the implementation of end-to-end digitalisation in the process industry is important to us. The development of innovative process measurement technology forms the basis for this in many areas.

Circular economy

Material efficiency and recycling of solid and liquid operating materials as well as residual and recyclable materials are the basis for sustainable development in Europe. We work with you to develop cost-effective solutions for your business.

Process optimisation

We develop optimisation potential for you in individual operational processes and process chains and focus on resource efficiency, quality, productivity, cost-effectiveness and environmental aspects.

News

Construction of our DR pilot plant starts

Save the date: BFI Colloquium on 29 April 2026

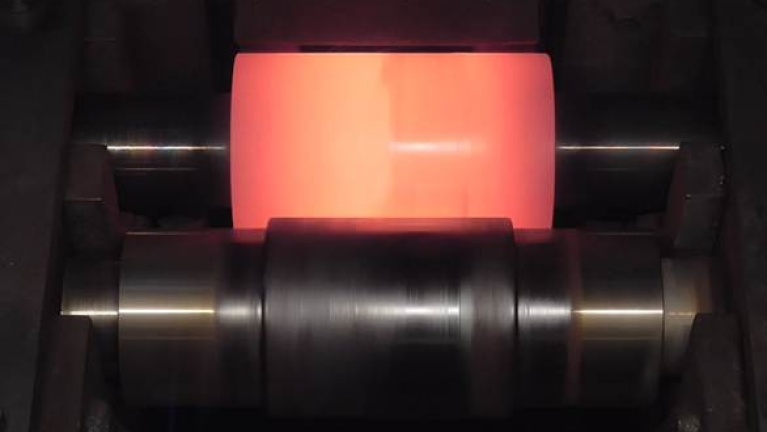

Pulsed Hydrogen Injection into the Blast Furnace Shaft (H2II)

Comprehensive Upgrade of the Two-Cylinder Hot-Wear Test Rig

Start of the research project “GeoCRM”