CO2 reduction and energy efficiency

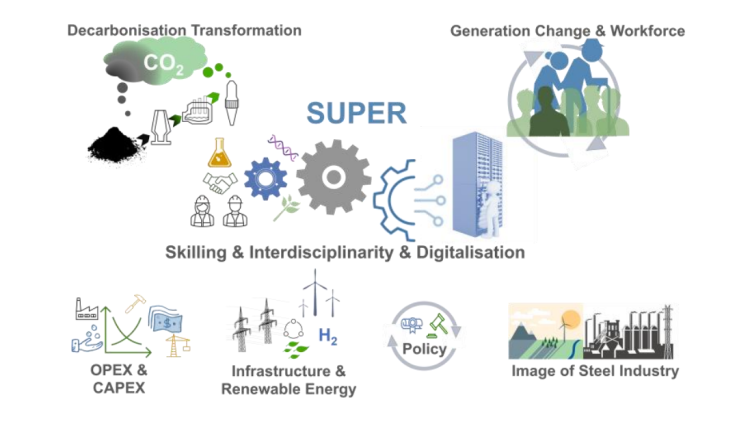

SUPER - Sustainable future steel production and people recruiting and skilling

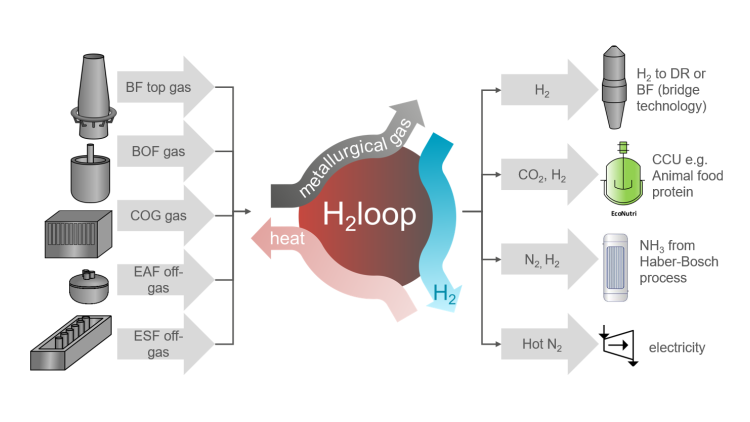

H2loop - Sustainable decarbonisation of integrated steel plants by hydrogen production from chemical looping

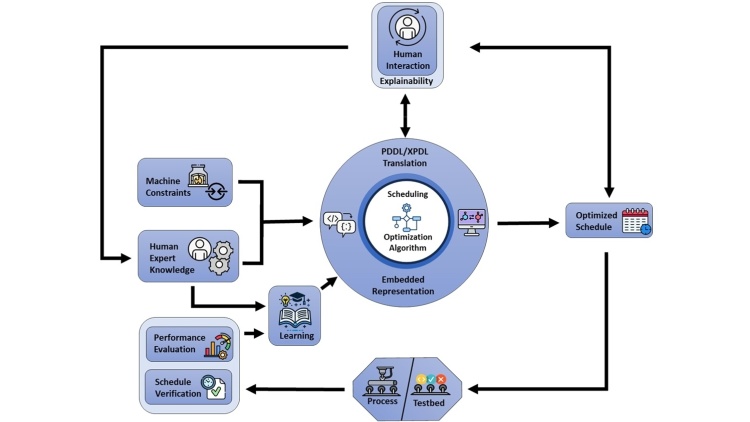

DeepScheduling - Explainable AI and Human-Centric Learning Solution Framework for Industrial Scheduling Optimization

Digitisation and process measurement technology

AgiFlex - Agent-based models minimizing carbon usage in flexible and efficient future integrated steelworks

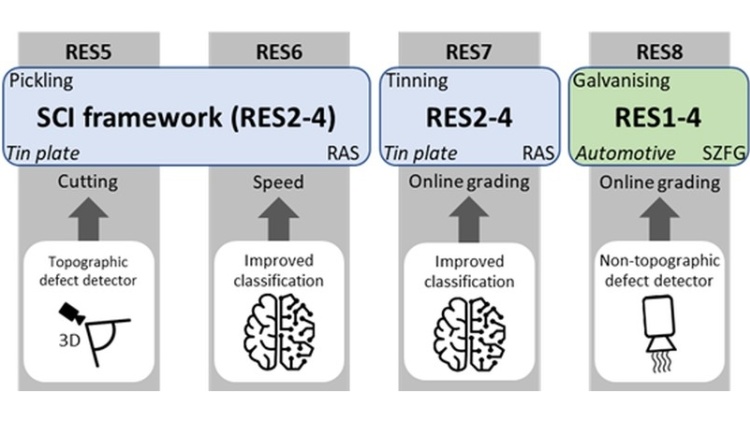

SufConInspect - Enabling zero-defect manufacturing for flat steel production by means of optimized inspection results and a new level of online surface quality control

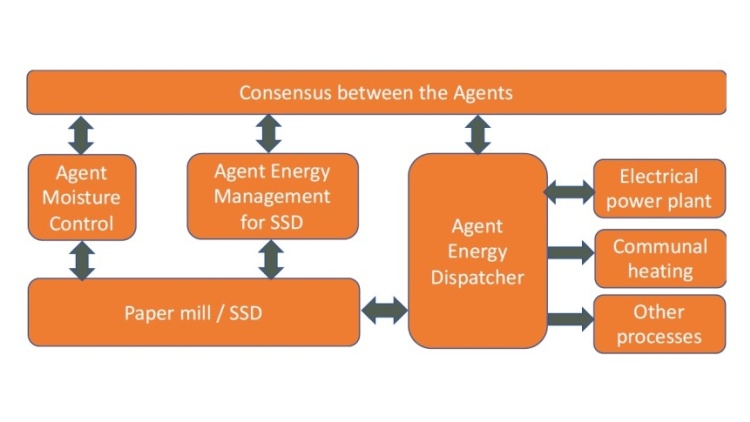

SteamDry - Superheated steam drying for sustainable and recyclable web-like materials

Circular economy

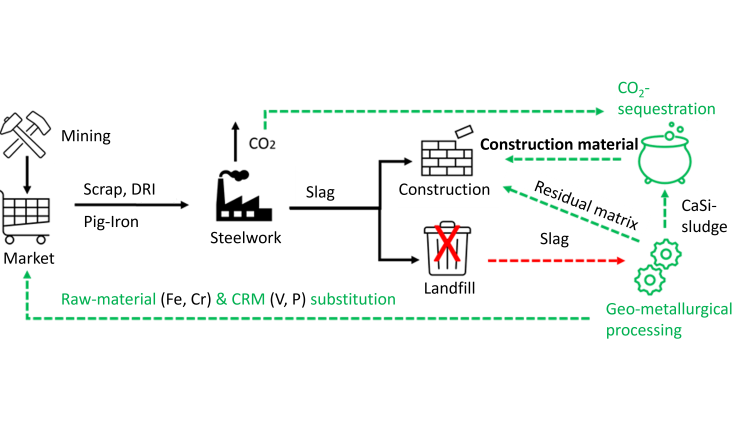

GeoCRM - Geometallurgical processing of steelmaking slag for recycling critical raw materials and CO2 binding

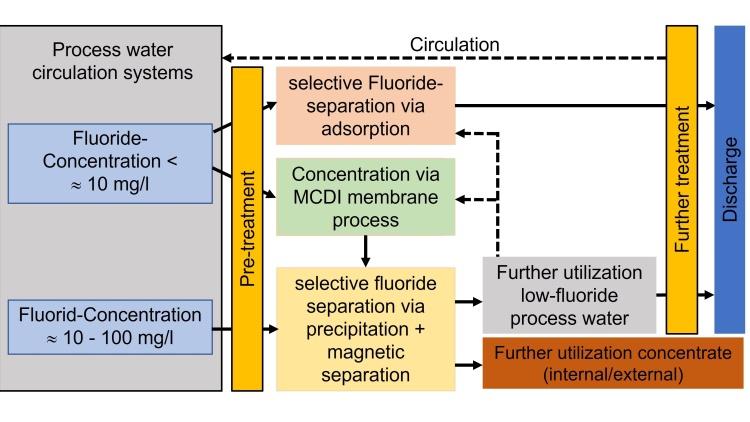

FluoridSelektiv - Process development for selective fluoride separation from industrial process water

ZinkAtline - Development of an atline measuring method for rapid analysis of the total zinc content in process water

Process optimisation

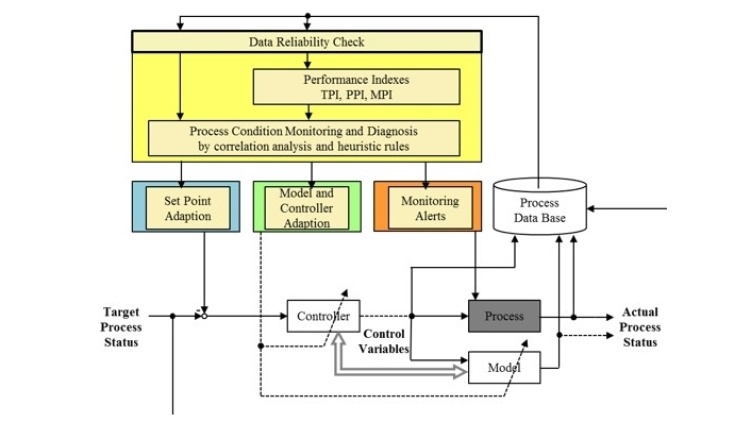

PerMonLiSt - Continuous performance monitoring and calibration of model and control functions for liquid steelmaking processes

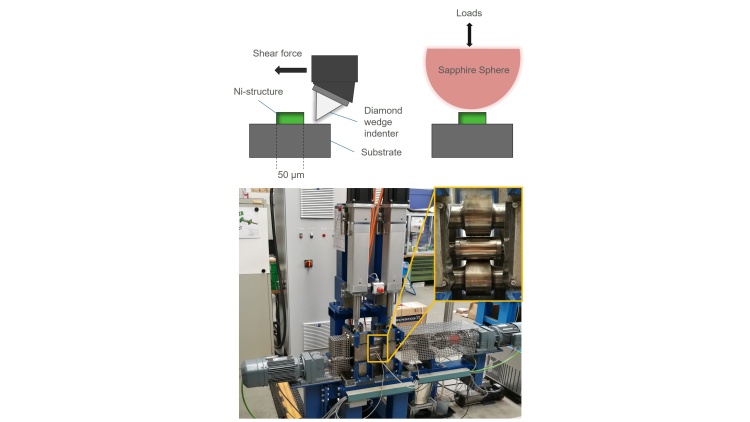

HydroPic - Analysis and control of hydrogen content during steelmaking